Riverway sludge treatment system and method

A river sludge and treatment system technology, applied in sludge treatment, water/sludge/sewage treatment, dehydration/drying/thickened sludge treatment, etc., can solve the problem of small space on the dredging ship site and achieve the purpose of preventing sediment Settlement, the effect of ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

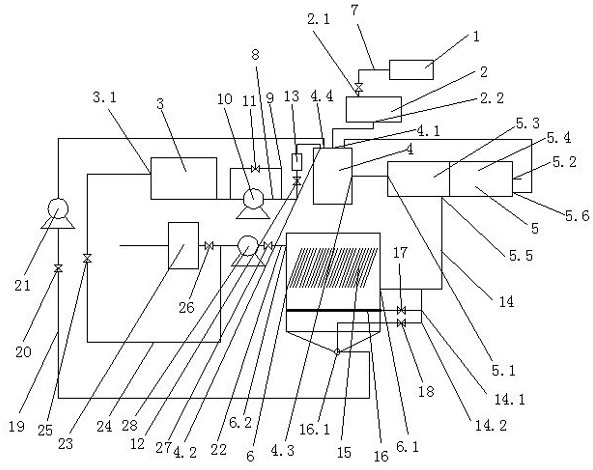

[0023] Embodiment 1: as figure 1 As shown, a river channel sludge treatment system includes a dredging ship 1, a grid machine 2, a dosing device 3, a mixing tank 4, a solid-liquid separator 5, a sedimentation tank 6, and the output pipe 7 of the dredging ship 1 is connected to the grid The material inlet 2.1 of the grid machine, the material outlet 2.2 of the grid machine are connected to the material inlet 4.1 of the mixing tank, the dosing device 3 is connected to the dosing port 4.2 of the mixing tank through the dosing pipe 8, and the dosing pipe 8 is provided with a dosing return pipe 9, The dosing pipe 8 is provided with a dosing pump 10, the dosing return pipe 9 is connected to both ends of the dosing pump 10, the dosing return pipe 9 is provided with a No. 4 valve 11, the dosing return pipe 9 and the dosing pipe 8 No. 5 valve 12 and flowmeter 13 are arranged in turn on the dosing pipe 8 at the dosing port 4.2 of the mixing tank between the connecting points, the materi...

Embodiment 2

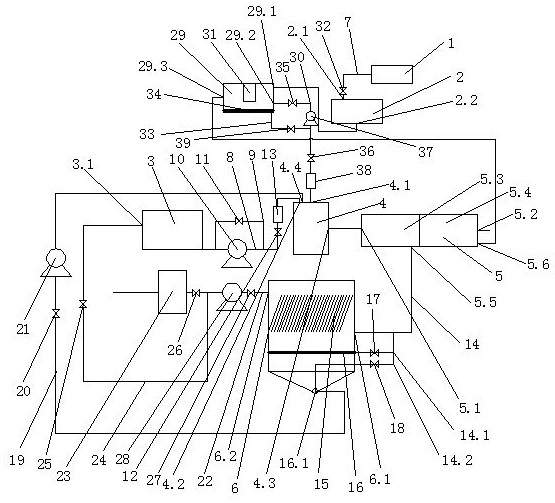

[0024] Embodiment 2: as figure 2As shown, a river channel sludge treatment system includes a dredging ship 1, a grid machine 2, a dosing device 3, a mixing tank 4, a solid-liquid separator 5, a sedimentation tank 6, and the output pipe 7 of the dredging ship 1 is connected to the grid The grid machine material inlet 2.1, a buffer tank 29 is arranged between the grid machine 2 and the mixing tank 4, the grid machine material outlet 2.2 is connected with the buffer tank material inlet 29.1, and the buffer tank material outlet 29.2 passes through the second pipeline 30 and the mixing tank material The inlet 4.1 is connected; the buffer tank 29 is provided with a liquid level gauge 31, and the output pipe 7 is provided with an output valve 32; the solid-liquid separator 5 is a multi-stage elliptical stacked solid-liquid separator 5, and the solid-liquid separator 5 separates the solid-liquid The two sections from the machine material inlet 5.1 to the sludge outlet 5.2 of the soli...

Embodiment 3

[0025] Embodiment 3: A river channel sludge treatment method, the river channel sludge is transported to the grid machine 2, and the sludge intercepted by the grid machine 2 enters the mixing tank 4; in the mixing tank 4, the flocculation agent is added through the dosing device 3 to flocculate Coagulation of chemicals and sludge; after coagulation, it enters the solid-liquid separator 5 for separation, and the separation is divided into two stages. The first stage is the concentration section 5.3, and the second stage is the pressing section 5.4. The concentrated water in the concentration section 5.3 passes through the sedimentation tank 6 for precipitation After discharge, the squeezed water in the squeezing section 5.4 flows back to the mixing tank 4 for further separation, and the mud cake separated by the solid-liquid separator 5 is discharged.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com