Processing method of small-caliber coil room-temperature tensile sample

A technology for tensile specimens and processing methods, which is applied in the field of tensile testing, can solve problems such as increasing the difficulty of clamping, difficulty in paralleling the two ends, and affecting the accuracy of results, so as to avoid difficulties in clamping operations, avoid test failures, and ensure accuracy sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

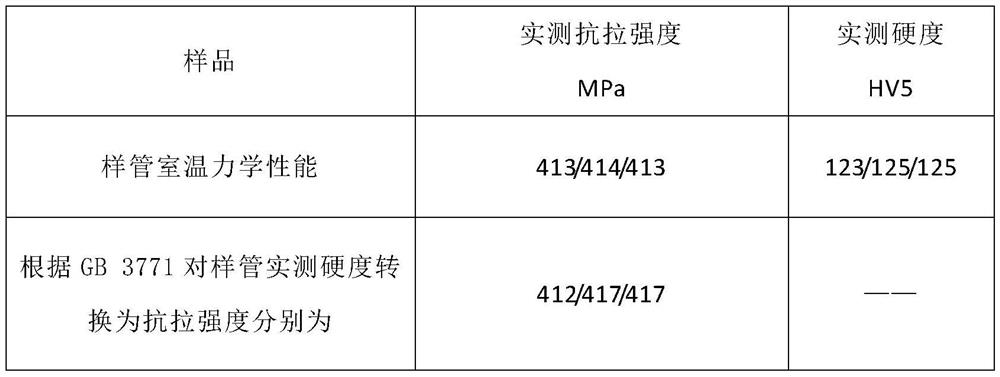

Embodiment 1

[0018] Select the H68 brass cold coil with a specification of Φ33×1.35mm to prepare the sample for room temperature tensile test. The processing method of the sample during the tensile test includes the following steps:

[0019] Step 1. Cut a section of sample tube with a length of 800mm from the coiled tube, mark point A and point B with a marker pen in the length direction of the sample tube, the length between point A and point B is 200mm, and the length between point A and point B The sample tube is used as the section to be tested, and the center angle corresponding to the sample tube between point A and point B is 150°;

[0020] Step 2. Straighten the sample tubes on the left side of point A and the right side of point B. The straightening speed is 3m / min. The other end must be supported to ensure that the section to be tested is not deformed;

[0021] Step 3. Cut the left and right straightening sections, and keep the clamping length required for the test, and the clam...

Embodiment 2

[0027] Select the H65 brass cold coil with a specification of Φ6×1mm to prepare the sample for room temperature tensile test. The processing method of the sample during the tensile test includes the following steps:

[0028] Step 1. Cut a section of sample tube with a length of 600mm from the coiled tube, mark point A and point B with a marker pen in the length direction of the sample tube, the length between point A and point B is 150mm, and the length between point A and point B The sample tube is used as the section to be tested, and the center angle corresponding to the sample tube between point A and point B is 175°;

[0029] Step 2. Straighten the sample tubes on the left side of point A and the right side of point B. The straightening speed is 1 / min. The other end must be supported to ensure that the section to be tested is not deformed;

[0030] Step 3. Cut the left and right straightening sections, and keep the clamping length required for the test, and the clamping ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com