Multi-fault shear wave velocity testing system for geotechnical model test

A geotechnical model and testing system technology, which is applied to the analysis of solids, instruments, and materials using sonic/ultrasonic/infrasonic waves. It can solve the problems of difficulty in accurate measurement of shear wave velocity, and achieve the effect of reducing test costs and avoiding interference.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

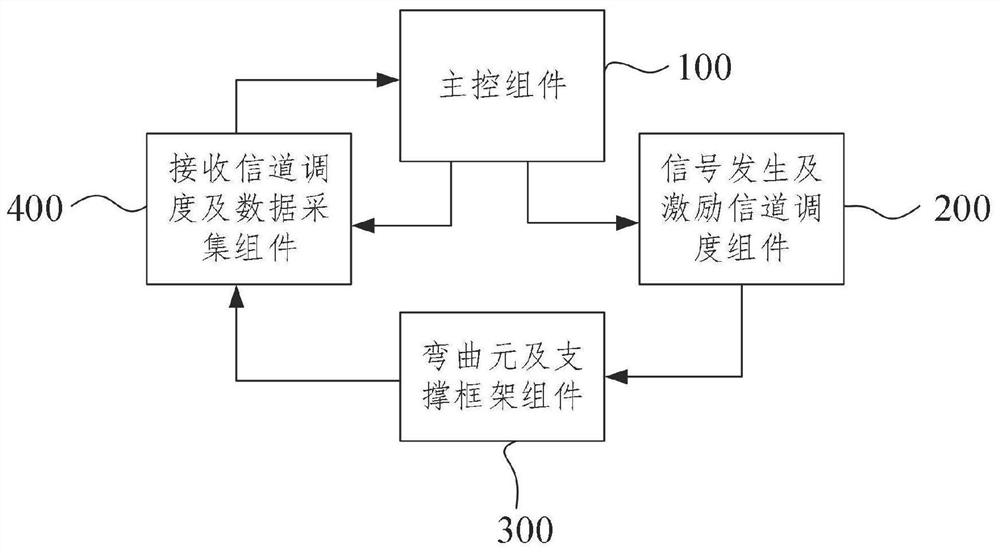

[0034] Such as figure 1 As shown, a multi-fault shear wave velocity testing system for geotechnical model tests in this embodiment includes a main control component 100, a signal generation and excitation channel scheduling component 200, a bending element and a supporting frame component 300, and a receiving channel scheduling component and the data acquisition component 400, the main control component 100 is electrically connected to the signal generation and excitation channel scheduling component 200 and the receiving channel scheduling and data acquisition component 400, the signal generation and excitation channel scheduling component 200 is electrically connected to the bending element and the support frame component 300, The bending element and the supporting frame assembly 300 are electrically connected to the receiving channel scheduling and data collection assembly 400 .

[0035] The technical effect achieved by this embodiment is: through a multi-fault shear wave ...

Embodiment 2

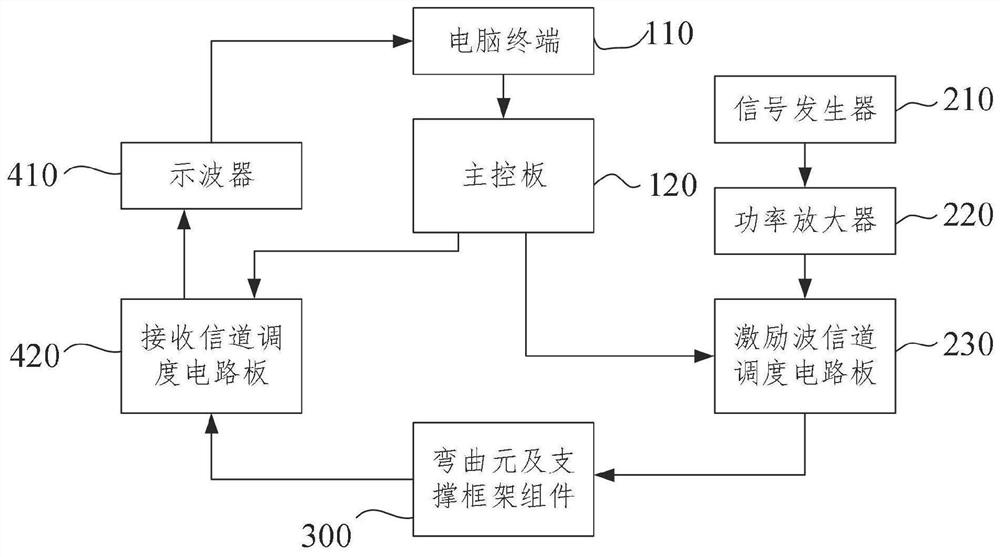

[0037] Such as Figure 2 to Figure 5 As shown, a multi-fault shear wave velocity testing system for geotechnical model tests in this embodiment includes all the technical features in Embodiment 1. In addition, the main control assembly 100 includes a computer terminal 110 and a main control Board 120, the computer terminal 110 is electrically connected with the main control board 120, the main control assembly 100 is used to realize the control of the excitation channel, the receiving channel and the control of the data acquisition system, and the main control board 120 is an Arduino board; in this embodiment , the main control component 100 also includes Arduino control software and PicoScope control software.

[0038] Secondly, the signal generation and excitation channel scheduling component 200 includes a signal generator 210, a power amplifier 220, and an excitation wave channel scheduling circuit board 230. The multiple groups of single-pulse electrical signals continuou...

Embodiment 3

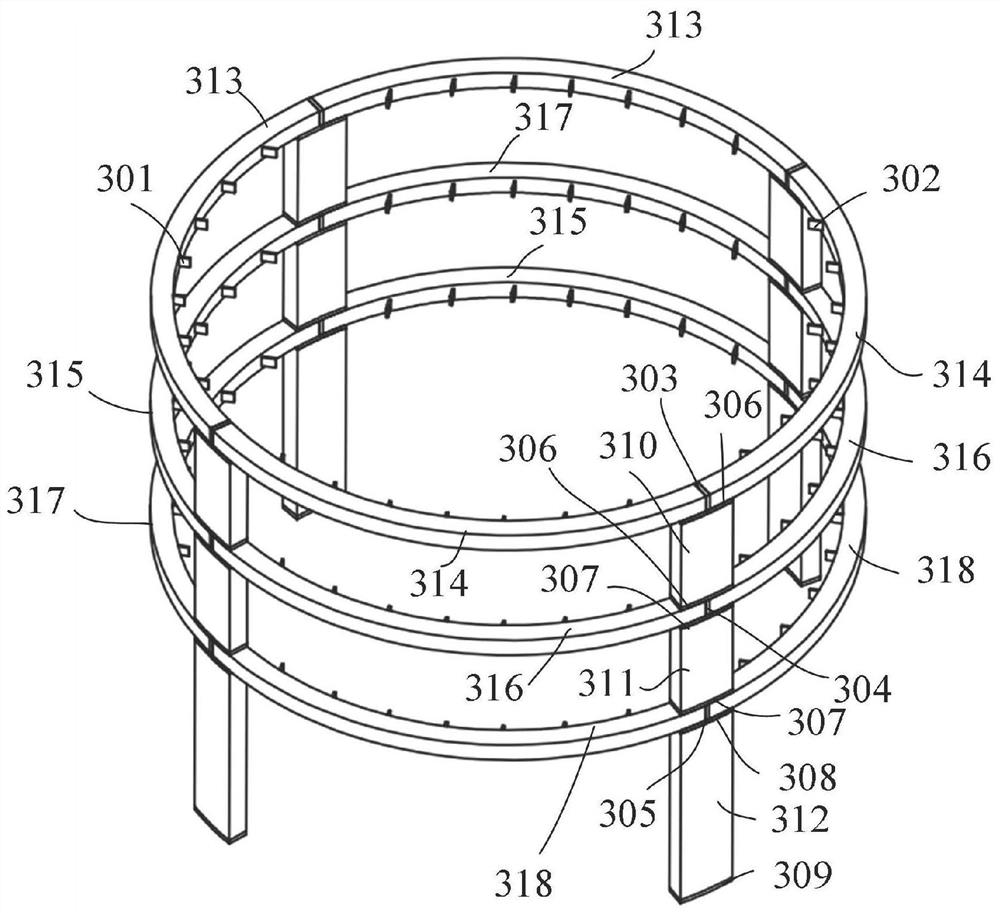

[0047] Such as Figure 6 As shown, a multi-fault shear wave velocity testing system for geotechnical model tests in this embodiment includes all the technical features in Example 2, and in addition, it also includes a model box for the model pile penetration test As an example, before making the model, the bending element and the supporting frame assembly 300 are arranged in the model box, and the center line of the bending element and the supporting frame assembly 300 coincides with the penetration center line of the model pile; after that, the sand rain method is used to make the model , according to the pile penetration speed, preset the excitation channel and the receiving channel scheduling program to ensure that the transmission of each transmitter 301 and the corresponding signal acquisition of the receiver 302 are completed in sequence when the specified penetration depth is reached. After the test is completed, based on the acquisition The multi-section shear wave vel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com