Electric heating furnace temperature control method based on improved fuzzy Smith-PID

A kind of temperature control method, technology of electric heating furnace

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further explained below in conjunction with the accompanying drawings.

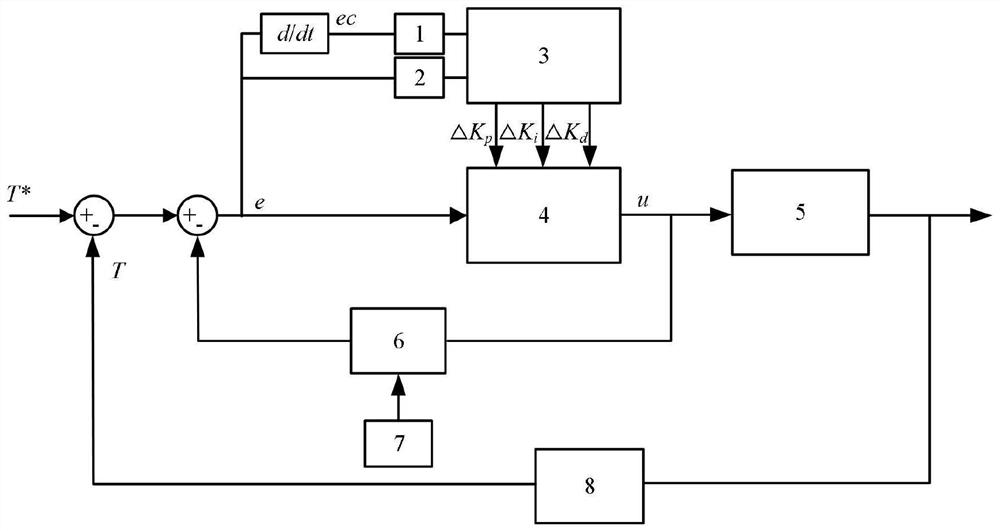

[0033] An improved fuzzy Smith-PID based electric heating furnace temperature control method is based on the system such as figure 1 As shown, it includes temperature deviation change rate quantization factor 1, temperature deviation quantization factor 2, fuzzy controller 3, PID controller 4, electric heating furnace 5, improved Smith predictor 6, nine-point controller 7, temperature sensor 8 .

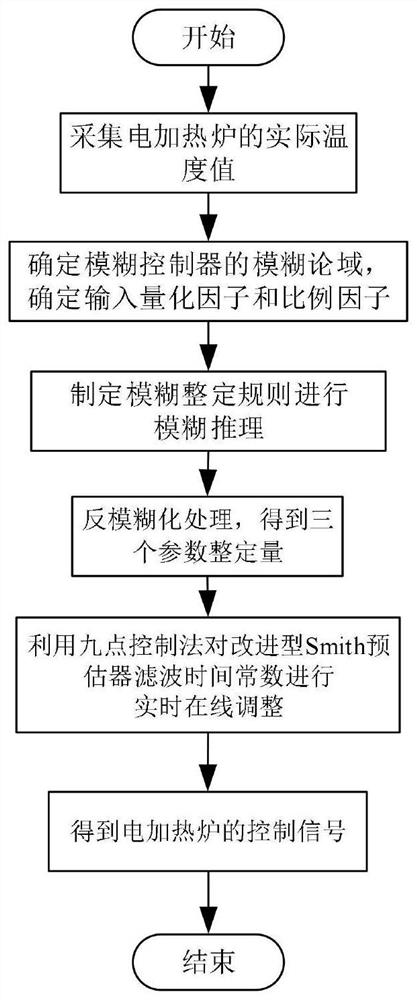

[0034] Such as figure 2 As shown, the method includes the following steps:

[0035] Step 1: Determine the input quantity of the fuzzy controller:

[0036] The actual temperature of the electric heating furnace is collected by the temperature sensor, and the actual temperature value is compared with the given value to obtain the temperature deviation e and the change rate ec of the deviation, which are used as the input of the fuzzy controller.

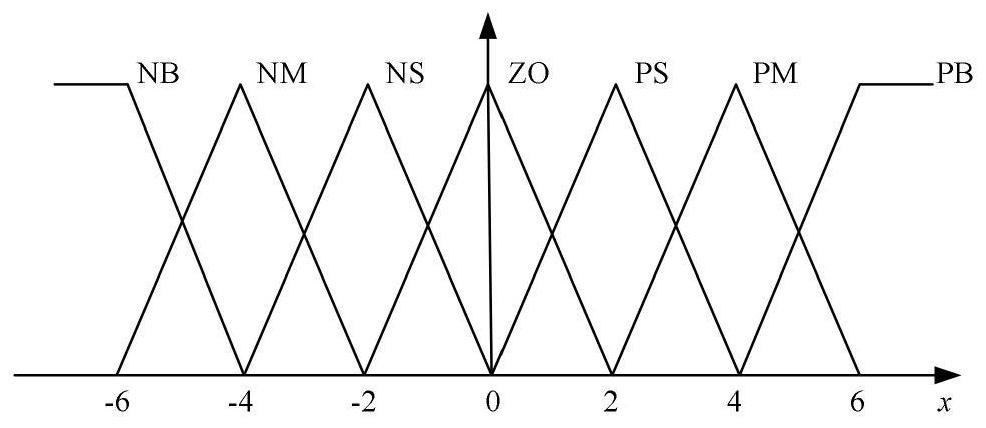

[0037] Step 2: Design the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com