Multi-winding laminated claw-pole motor

A claw-pole motor, multi-winding technology, applied to the shape/style/structure of winding conductors, electrical components, electromechanical devices, etc. Efficiency and power factor improvement, good self-starting capability, and the effect of simplified rotor structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

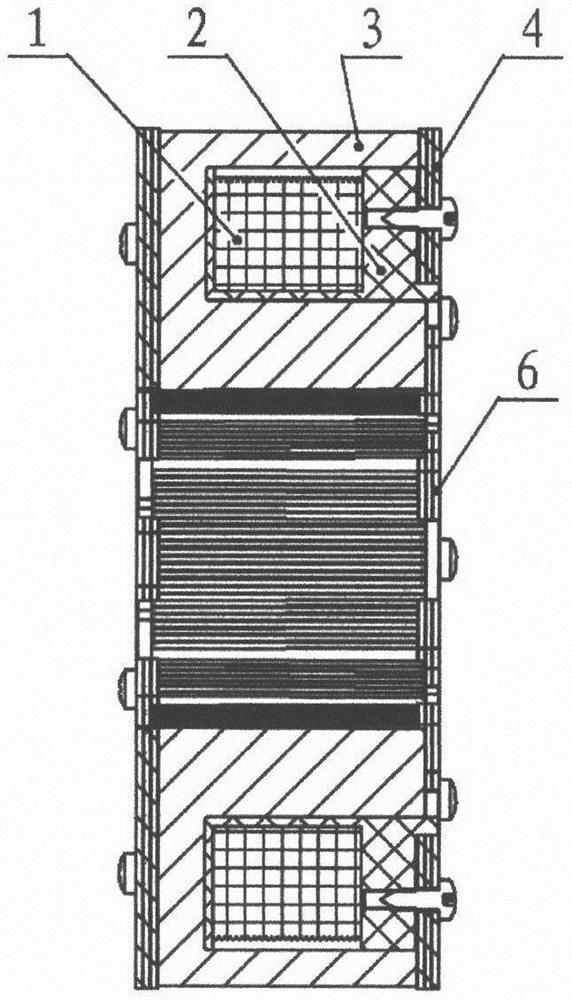

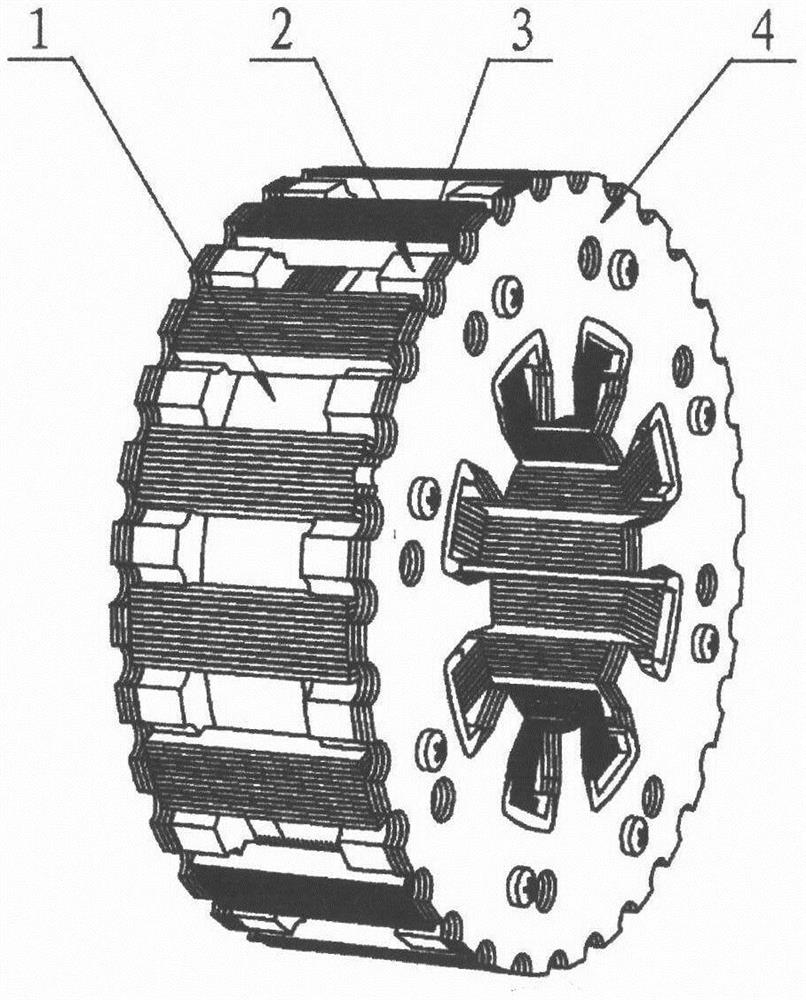

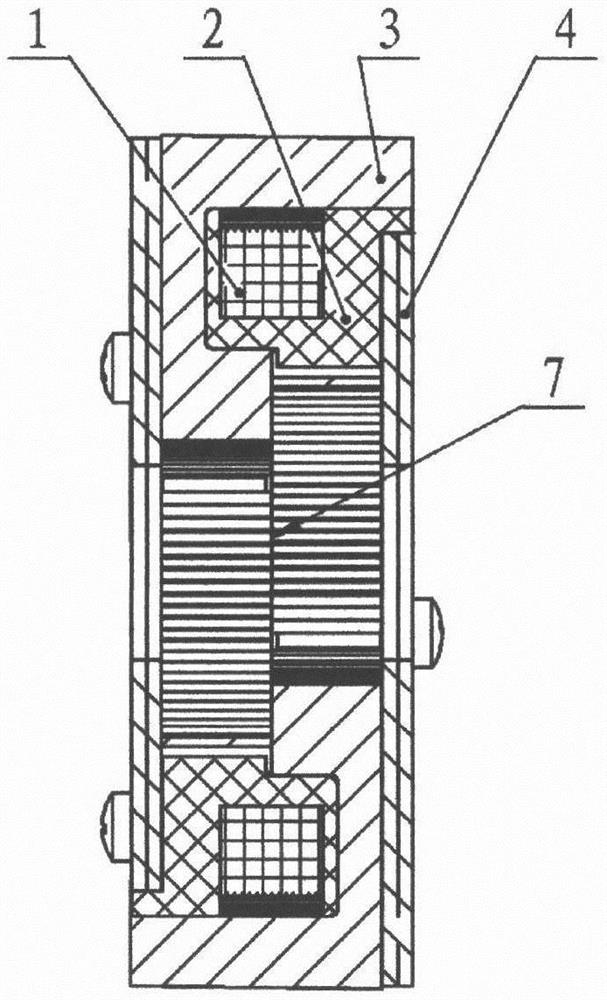

[0021] figure 1 , figure 2 It is a cross-sectional view and a three-dimensional view of the single winding combination of the inner rotor motor of the present invention. The coil (1) is wound on the skeleton (2). Since the skeleton (2) is an open structure, the winding is very convenient and efficient. The skeleton (2) uses engineering Made of plastic, on the one hand, it can improve the insulation level of the winding (1), and on the other hand, it can also provide installation support for the laminated claw poles (3). Multiple sets of laminated claw poles (3) are respectively installed into the skeleton (2) from both ends ), the two groups of laminated end plates (4) are respectively attached to the laminated claw poles (3), and are fixed on the two ends of the frame (2) to form a single winding combination (5). When working, the permanent magnet inner rotor is placed in the inner cavity of the motor stator, and the flux chain direction is: N pole of the permanent magnet i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com