Circulating desanding device for sewage treatment

A sewage treatment and inclined plate technology, applied in separation methods, filtration separation, chemical instruments and methods, etc., can solve the problems of low filtration efficiency, insignificant effect, inconvenient collection of gravel, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

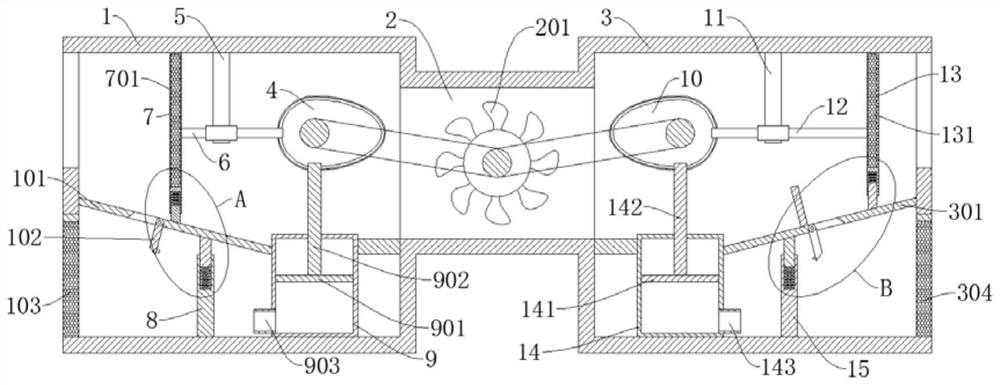

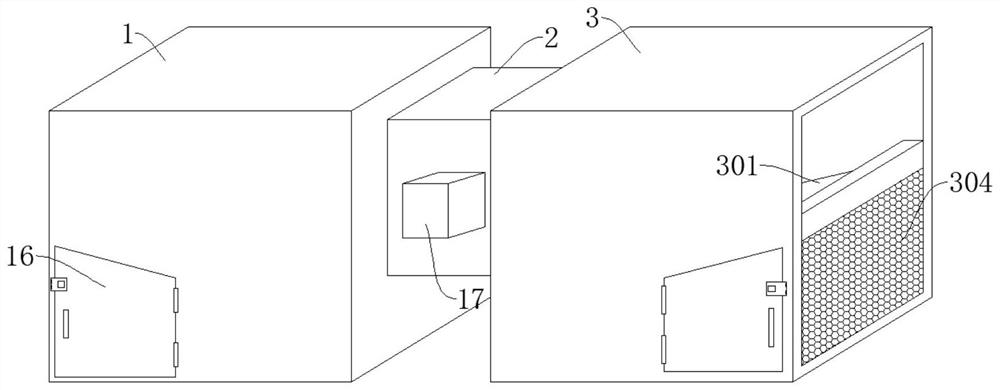

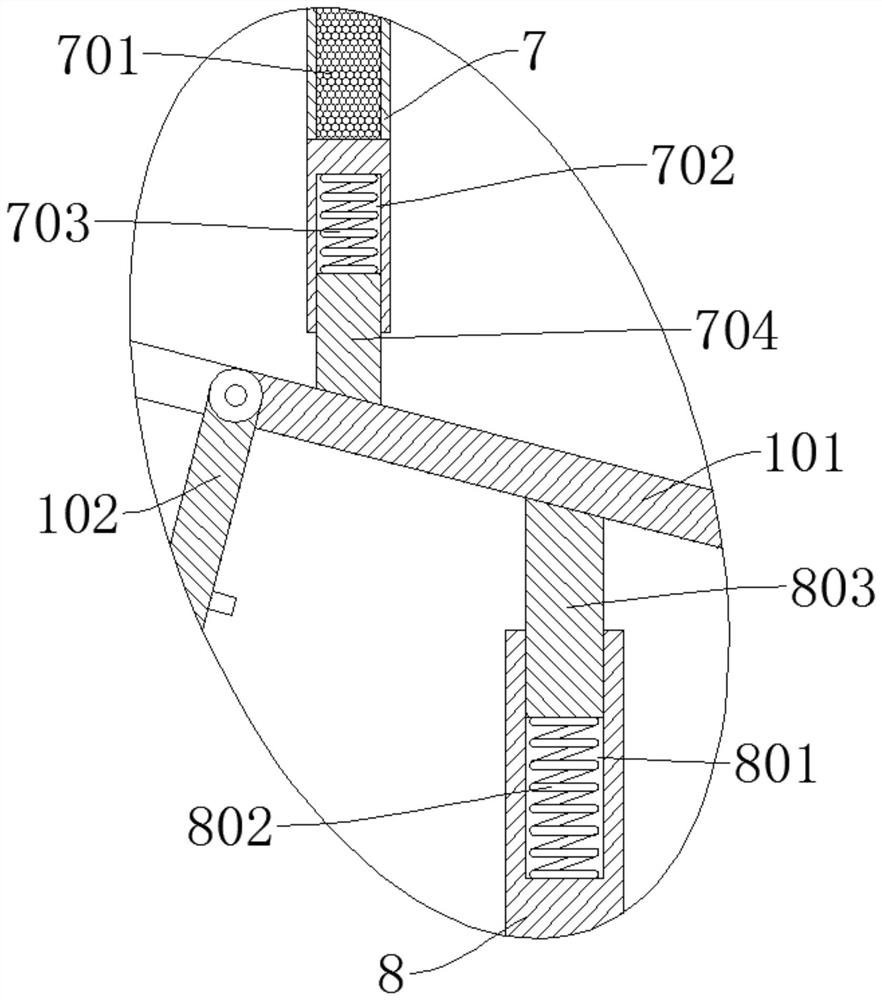

[0037] refer to Figure 1-7 , a kind of circulating sand removal device for sewage treatment, comprising a first sand removal chamber 1, a pressurization chamber 2, the first sand removal chamber 1, and a pressurization chamber 2, characterized in that the first sand removal chamber 1 and the pressurization chamber 2 Fixed connection, the impeller 201 is rotatably connected in the pressurization chamber 2, the first desanding chamber 1 is provided with a water inlet, the first desandering chamber 1 is rotatably connected with the first cam 4, and the first desandering chamber 1 is fixed The first slant plate 101 is connected, the first sand collecting chamber is arranged under the first slant plate 101, the first sieve plate 7 is slidably connected above the first slant plate 101, and the first sieve plate 7 is provided with a first filter screen 701 The end of the first sieve plate 7 close to the first inclined plate 101 is provided with a first chute 702, the first chute 702...

Embodiment 2

[0040] refer to Figure 1-7 , a kind of circulating desanding device for sewage treatment, which is basically the same as embodiment 1, furthermore, it also includes a second desandering chamber 3, which is fixedly connected to the pressurization chamber 2 away from the first desandering chamber One end of the chamber 1, the second desander chamber 3 is provided with a water outlet, the second desander chamber 3 is rotatably connected with a second cam 10, and the second desander chamber 3 is fixedly connected with a second inclined plate 301, the second The second sieve plate 13 is slidably connected to the inclined plate 301, the second sieve plate 13 is provided with a third filter screen 131, the second sieve plate 13 is provided with a third chute 132 near the end of the second inclined plate 301, and the third sieve plate 13 is provided with a third chute 132. A third sealing plate 133 is slidably connected in the chute 132, and one end of the third sealing plate 133 loc...

Embodiment 3

[0043] refer to Figure 1-7 , a circulating desanding device for sewage treatment, which is basically the same as Embodiment 1, furthermore, the side edges of the first cam 4 and the second cam 10 are provided with slide rails 401, the first push rod 6, the first connecting Rod 902, the second push rod 12, the second connecting rod 142 are all provided with pulley 904 near one end of first cam 4 or second cam 10, and pulley 904 is matched with slide rail 401, and the setting of pulley 904, slide rail 401 is convenient. The first push rod 6 , the first connecting rod 902 , the second push rod 12 , the second connecting rod 142 slide relative to the first cam 4 and the second cam 10 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com