Condensation warm air chimney mixed flue gas whitening system

An external mixing and flue gas technology, applied in the field of flue gas whitening, can solve the problems of poor heat transfer performance, small heat transfer area, large equipment, etc., and achieve the effects of low operating cost, low investment and light weight.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

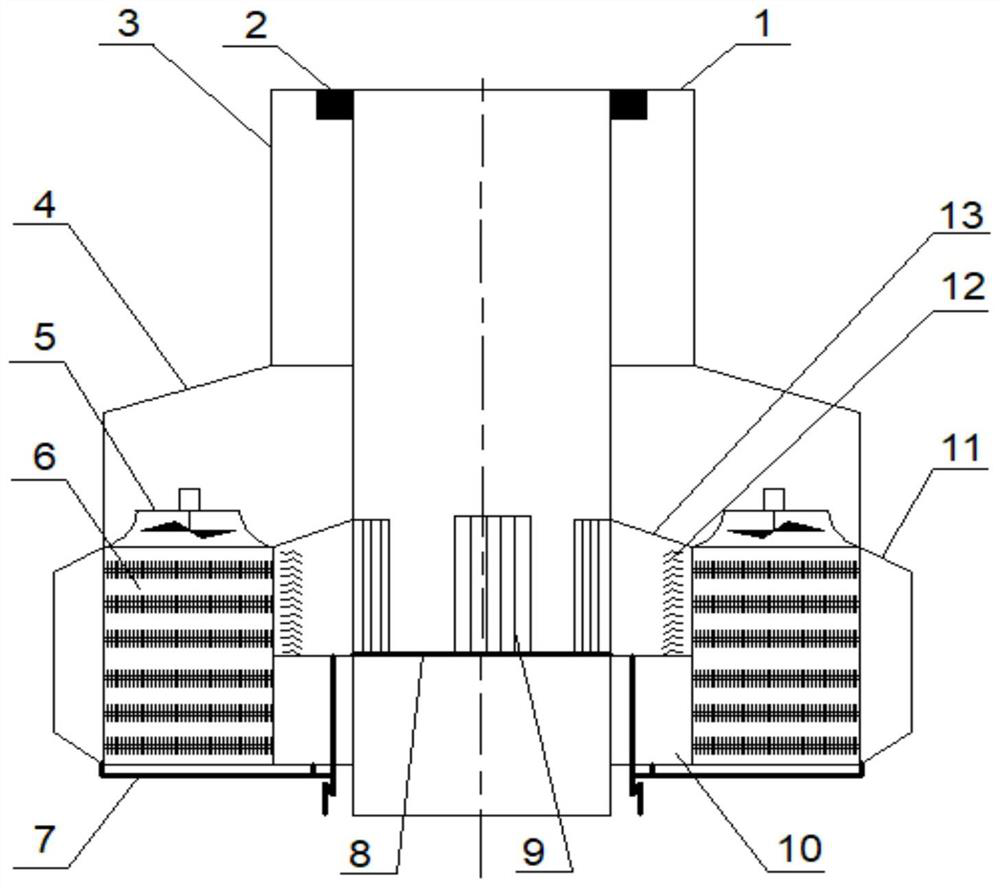

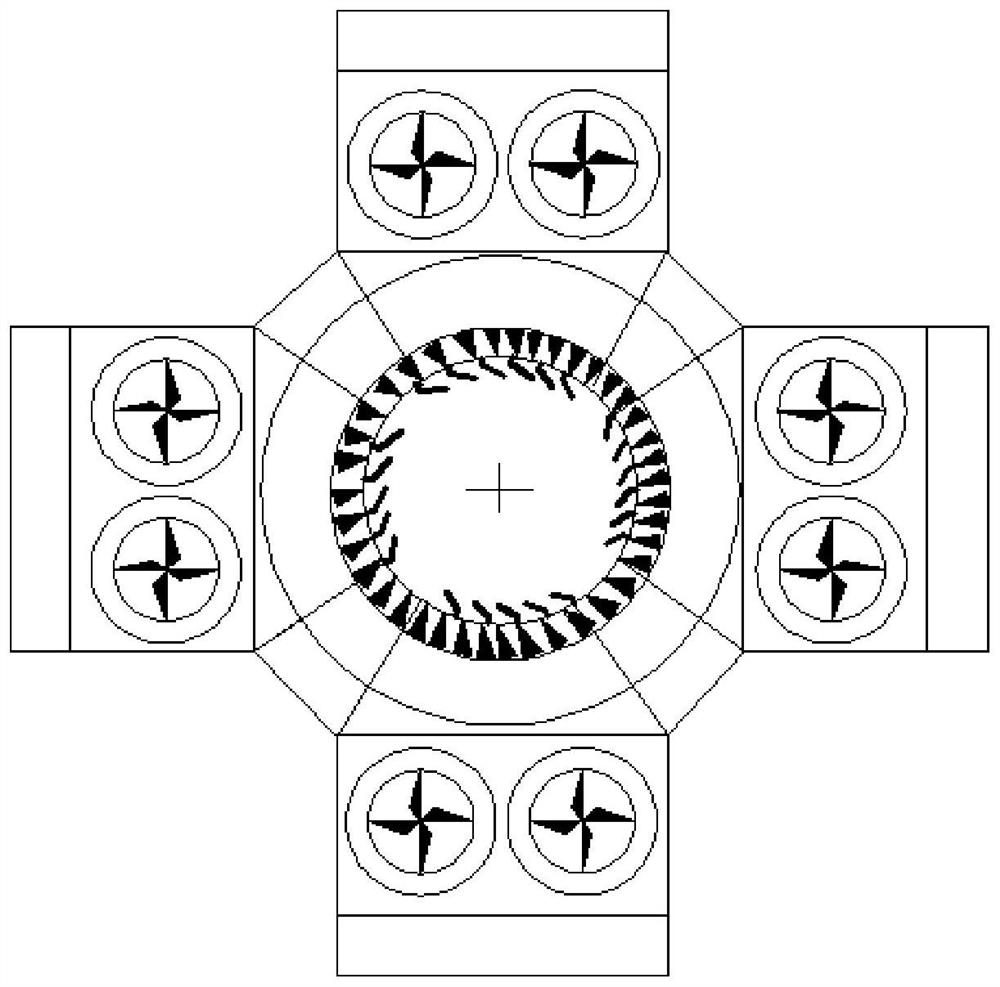

[0019] like Figure 1-Figure 2 As shown, the present invention consists of a chimney 1, a swirl ring 2, a warm air cylinder 3, a warm air chamber 4, a fan 5, an air-cooled condenser 6, a drain pipe 7, a chimney partition plate 8, a deflector plate 9, and a smoke outlet interface 10. Composed of steering cover 11, demister 12, and smoke return interface 13.

[0020] The chimney 1 is partitioned by the chimney partition plate 8, and four windows are opened on the upper and lower sides, respectively connected to the flue gas outlet interface 10, the flue gas return interface 13, and the air-cooled condenser 6. Four air-cooled condensers 6 are symmetrically arranged, with stainless steel-aluminum finned tubes as heat exchange elements, and the upper and lower processes are connected by a steering cover 11 .

[0021] The flue gas flows and condens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com