Limestone slurry preparation system and limestone slurry preparation method

A limestone slurry and preparation system technology, which is applied in the field of limestone slurry preparation system, can solve the problems affecting the atomization effect of the spray layer of the slurry circulating pump, the wear of the spray layer pipeline and nozzle, and the increase of the maintenance workload of the unit, so as to shorten the Downtime maintenance time, maintenance residence time, and cost-saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

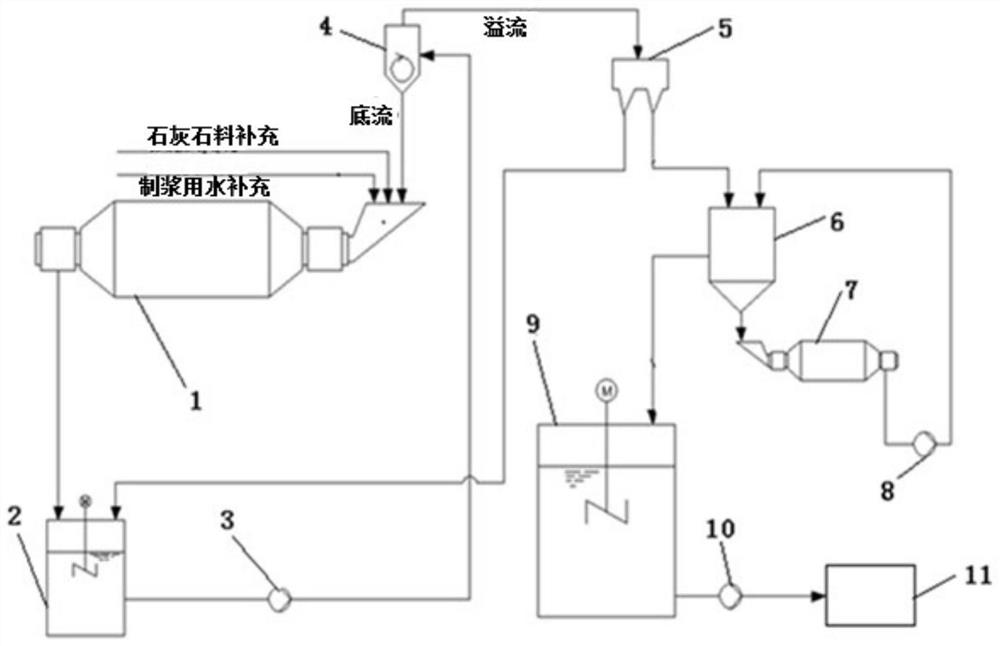

[0019] A limestone slurry preparation system of the present invention, such as figure 1 As shown, it includes primary wet ball mill 1, limestone and pulping water are replenished through the inlet of primary wet ball mill 1, and the outlet of primary wet ball mill 1 is connected to recirculation tank 2; recirculation tank 2 swirls with limestone slurry through slurry circulation pump 3 The bottom flow port of the limestone slurry cyclone 4 is connected to the inlet of the primary wet ball mill 1, the overflow port of the limestone slurry cyclone 4 is connected to the distributor 5, the distributor 5 is connected to the recirculation box 2, and the distributor 5 is also connected to The inlet of the secondary separator 6, the bottom outlet of the secondary separator 6 is connected to the inlet of the secondary wet ball mill 7, the outl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com