A kind of preparation method of functional calcium carbonate

A technology of functional calcium carbonate and heavy calcium, applied in the direction of calcium carbonate/strontium/barium, chemical instruments and methods, calcium/strontium/barium compounds, etc., can solve the problems of high energy consumption, high oil absorption value, and complicated composite methods , to achieve the effect of reducing energy consumption and equipment wear, reducing production energy consumption and cost, and improving stability and controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

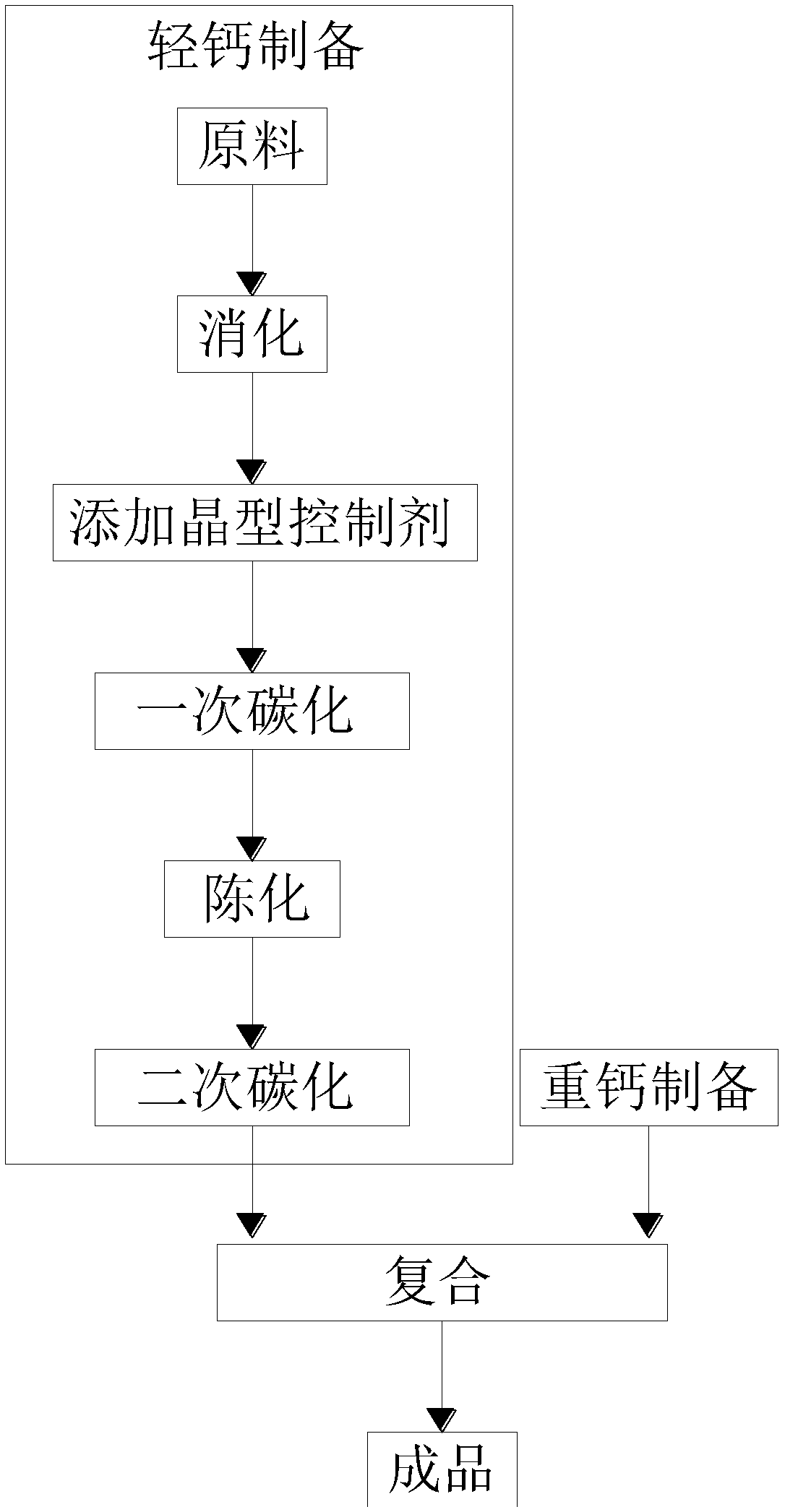

[0036] Such as Figure 1~5 Shown, the preparation method of a kind of functional calcium carbonate that the present invention proposes may further comprise the steps:

[0037] Preparation of heavy calcium: crush and grind the raw material calcite or wollastonite;

[0038] Preparation of light calcium: prepare light calcium according to the crystal form and particle size of heavy calcium;

[0039] Compounding: put the prepared 1-10 parts of heavy calcium and 100 parts of light calcium into the compounding tank and stir evenly;

[0040] Finished product: The compounded product is dehydrated and dried to make a finished product.

[0041] Described light calcium preparation step is specifically,

[0042] Digestion: Digest the raw material calcium oxide and water at a ratio of 1:8;

[0043] Add crystal form control agent: After digestion is completed, add the corresponding crystal form control agent to the slurry according to the heavy calcium crystal form, and stir well;

[0...

Embodiment 1

[0056]The raw material calcite or wollastonite is crushed and ground until it is made into heavy calcium with a particle size of 1200 mesh. Put calcium oxide into water according to the ratio of calcium oxide to water 1:8 for digestion treatment, then add crystal form control agent to the digested slurry and stir well, the added amount is 0.1% of the added amount of calcium oxide. After stirring well, the primary carbonization starts, and the primary carbonization stops when the pH value of the slurry reaches 8.5, and then the slurry is placed in the slurry storage tank for aging. The aging time is 4 hours, and then the secondary carbonization of the slurry is carried out. Stop when the pH value reaches 7.0, and the preparation of light calcium is completed. Among them, the slurry needs to be stirred at a constant speed during the primary carbonization and secondary carbonization, the stirring speed is 100 rpm, the carbonization temperature is 65°, and the carbonization time i...

Embodiment 2

[0059] The raw material calcite or wollastonite is crushed and ground until it is made into heavy calcium with a particle size of 1200 mesh. Put calcium oxide into water according to the ratio of calcium oxide to water 1:8 for digestion treatment, then add crystal form control agent to the digested slurry and stir well, the added amount is 0.2% of the added amount of calcium oxide. After stirring well, the primary carbonization starts, and the primary carbonization stops when the pH value of the slurry reaches 8.5, and then the slurry is placed in the slurry storage tank for aging. The aging time is 4 hours, and then the secondary carbonization of the slurry is carried out. Stop when the pH value reaches 7.0, and the preparation of light calcium is completed. Among them, the slurry needs to be stirred at a constant speed during the primary carbonization and secondary carbonization, the stirring speed is 100 rpm, the carbonization temperature is 65°, and the carbonization time ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size distribution | aaaaa | aaaaa |

| particle size distribution | aaaaa | aaaaa |

| particle size distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com