A kind of preparation method of graphene-aluminum mixed powder

A graphene and mixed powder technology, applied in chemical instruments and methods, carbon compounds, metal processing equipment, etc., can solve problems such as uneven dispersion of graphene, graphene damage, etc., and achieve difficult desorption and separation, and finished products have a high degree of dispersion. , the effect of promoting intermolecular interactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

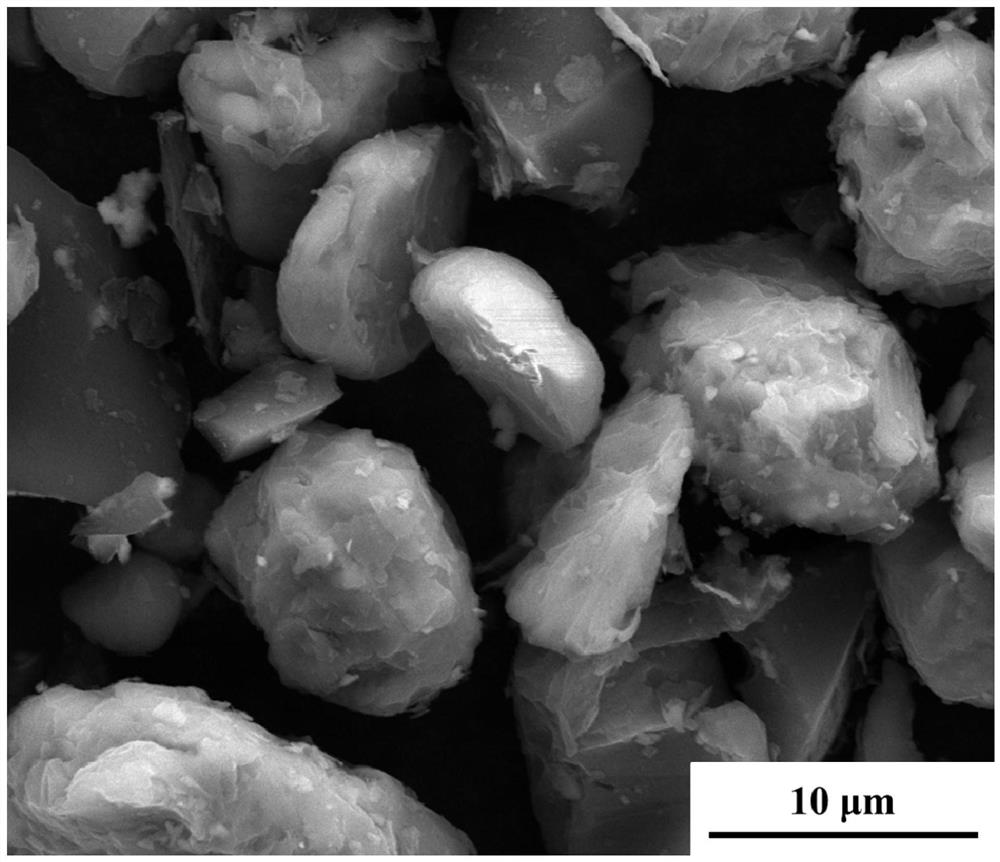

Image

Examples

specific Embodiment approach 1

[0019] Specific embodiment one: present embodiment graphene-aluminum mixed powder preparation method is finished according to the following steps:

[0020] 1. Weighing: Weigh graphene and aluminum metal powders respectively according to mass fraction;

[0021] 2. Graphene pretreatment: add the graphene weighed in step 1 into an ammonia solution, and stir under ultrasonic conditions to obtain a pretreated graphene solution;

[0022] 3. Aluminum metal powder pretreatment: add the aluminum metal powder weighed in step 1 into the tin chloride solution, and stir under ultrasonic conditions to obtain a pretreated aluminum metal powder solution;

[0023] 4. Mixing:

[0024] Mix the pretreated graphene solution in step 2 and the pretreated aluminum metal powder solution in step 3, and stir under ultrasonic conditions to obtain a graphene-aluminum dispersion;

[0025] 5. Filter and dry the graphene-aluminum dispersion obtained in step 4 to obtain a graphene-aluminum mixed powder, whi...

specific Embodiment approach 2

[0031] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is: when graphene and aluminum metal powder are weighed respectively by mass fraction in step 1, the mass fraction of graphene is 0.1~5%, and the balance is aluminum metal powder.

specific Embodiment approach 3

[0032] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: NH in the ammonia solution described in step two 3 ·H 2 The mass fraction of O is 5-30%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| bending strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com