Axle box guide pillar positioning type three-axis welding self-guiding radial wagon bogie

A railway freight car, positioning technology, applied in the direction of bogie, railway car body parts, axle box installation, etc., can solve the problems of eccentric brake shoe wear, serious wear, excessive self-weight, etc., and achieve simple mechanical structure and high transmission efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

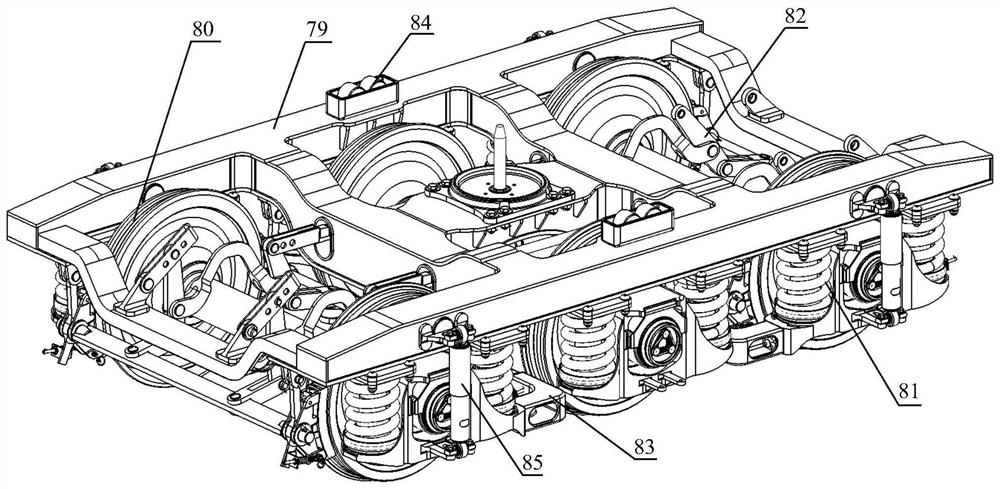

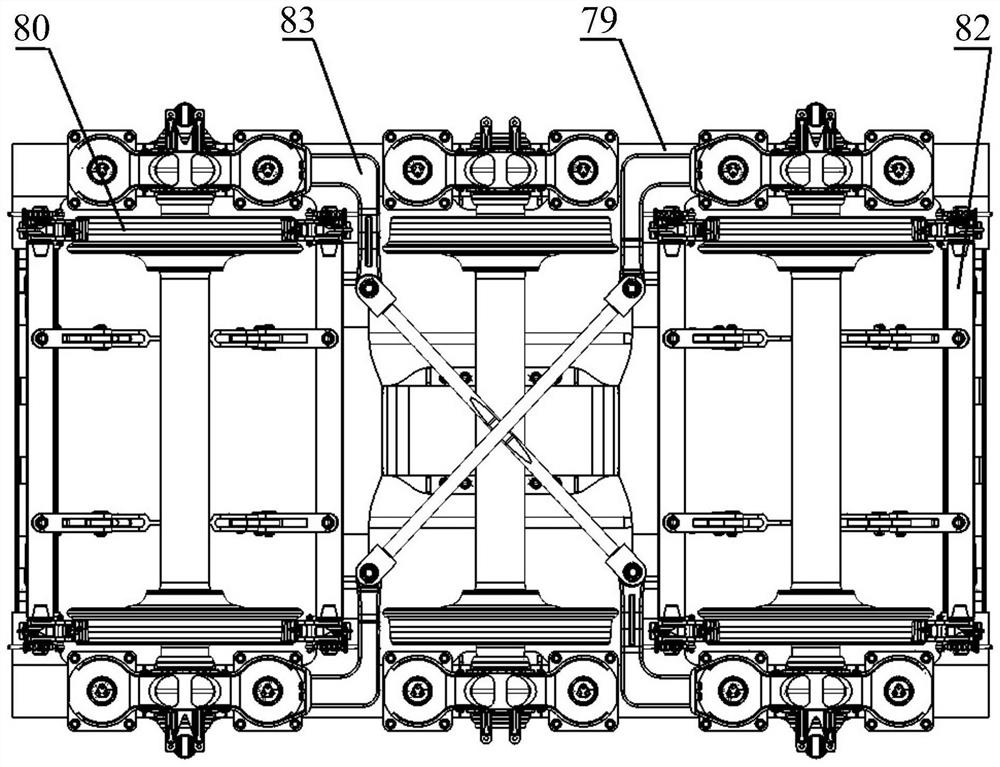

[0089] Such as figure 1 and figure 2 The illustrated three-axis welded self-guiding radial railway freight car bogie with axle box guide column positioning type includes a frame 79, three sets of wheel set assemblies 80 matched with the frame 79, and the two ends of the main shaft of the wheel set assembly 80 are They are all matched with an axle box suspension device 81, and also include a basic brake device 82 for braking the wheel set assembly 80. The main shafts of the wheel set assemblies 80 on both sides are end shafts, and the two end shafts correspond to The four axle box suspension devices 81 are connected by a cross connection device 83, and a vertical hydraulic damping device 85 is installed between the four axle box suspension devices 81 corresponding to the two end shafts and the frame 79; Clearance side bearings 84 are all set on both sides along the track direction on the 79.

[0090] The wheel rim of the wheel set assembly 80 located in the middle is thinner...

Embodiment 2

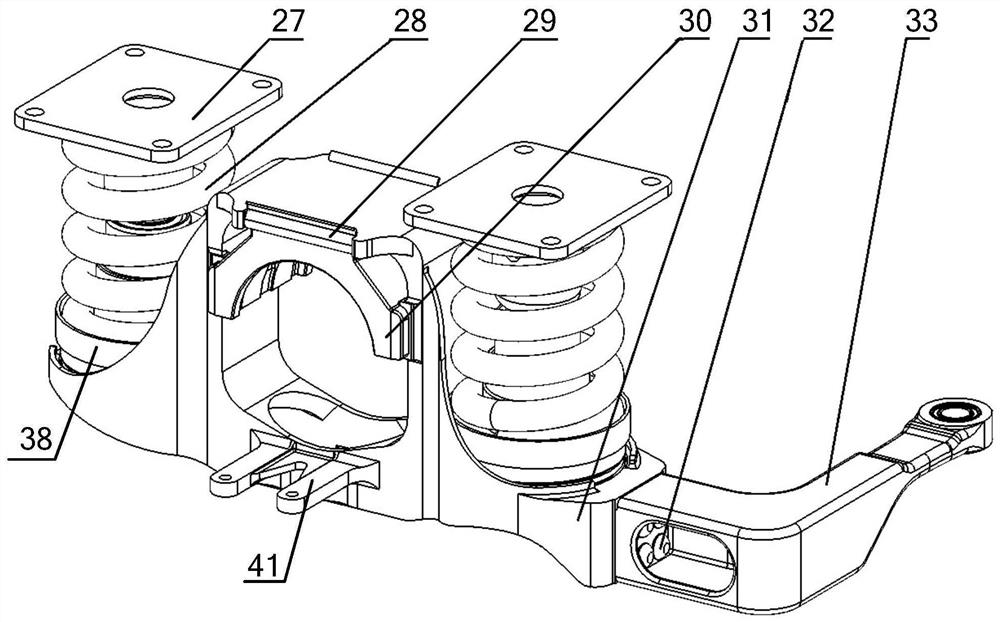

[0096] On the basis of Embodiment 1, the axle box suspension device 81 is as Figure 3 ~ Figure 4 As shown, it includes an axle box 31 for cooperating with rolling bearings, and an axle box spring 28 matched with the axle box 31. The bearing saddle 30 is detachably connected to the axle box 31, and the axle box 31 and the bearing saddle 30 are jointly formed. In the installation part of the rolling bearing, a number of wear plates 29 are installed on the top of the bearing saddle 30; it also includes a guide post assembly arranged on both sides of the axle box 31, and the axle box spring 28 is located in the guide post assembly assembly. The guide post assembly assembly includes a guide post assembly 27 for installation on the welding frame, a guide post assembly 34 fixed below the guide post assembly 27, an elastic positioning sleeve 35 fixed below the guide post assembly 34; It includes a positioning seat composition 40 located on the axle box 31, an annular buffer pad 39 is...

Embodiment 3

[0104] On the basis of Embodiment 1, the foundation braking device such as Figure 5 ~ Figure 10 As shown, the two-side brake shoe suspension brake is adopted for the two-end wheel sets, the plate beam type brake beam double-rod structure, and the middle wheel set has no brake. specific:

[0105] Including plate beam type brake beam 1, fixed lever fulcrum 2, fixed lever 3, bow tie rod 4, middle lever 5, straight tie rod 6, floating lever 7, brake shoe head automatic adjustment device 8, high-friction composite brake shoe 9. Brake shoe support 10, brake shoe support crane 11.

[0106] The main beam of the brake beam 1 is a straight plate brake beam with a plate structure, and the center position of the straight plate brake beam is symmetrically riveted with one pillar 13 on both sides, and the end shafts 12 are welded along the longitudinal surface at both ends; the brake shoe support 10 is a cast structure, Its back is a double-walled web groove structure, and a circular thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com