Ion co-doped beta-dicalcium silicate powder as well as preparation method and application thereof

A technology of dicalcium silicate and co-doping, which is applied in the direction of silicate, alkaline earth metal silicate, chemical instruments and methods, etc., can solve the problems of long synthesis time, expensive raw materials, high reaction temperature, etc., and achieve good slowness release ability, no environmental pollution, and low synthesis temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

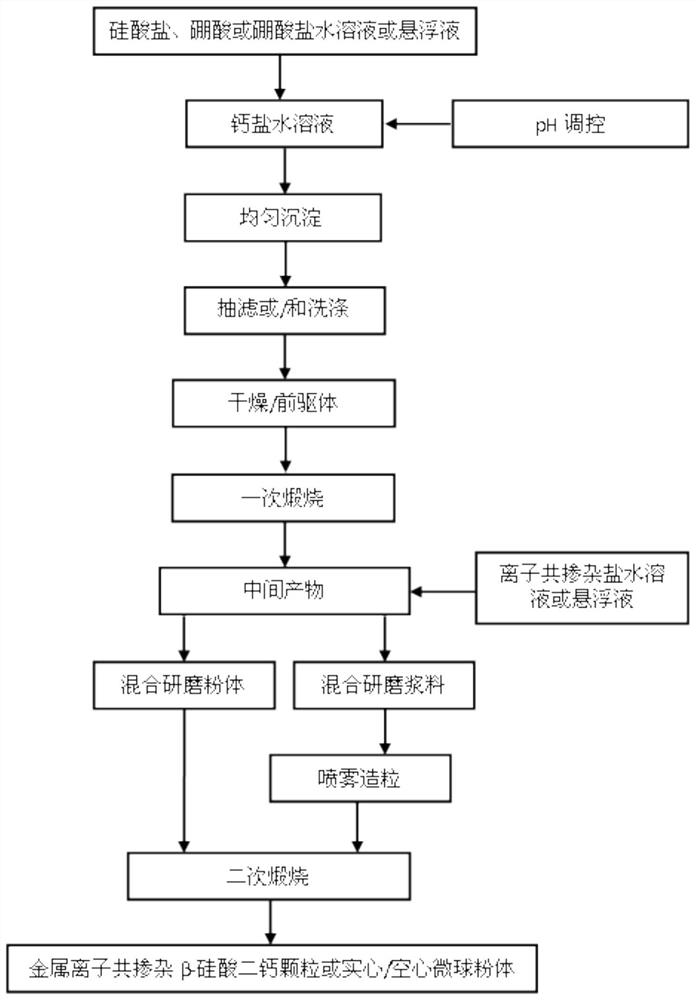

Method used

Image

Examples

Embodiment 1

[0041] β-Ca 1.7 (Sr 0.1 mn 0.1 Zn 0.1 ) SiO 4 Granular powder

[0042] The first step: weigh 2.362 grams of Ca (NO 3 ) 2 4H 2 O was dissolved in 100mL deionized water to prepare a calcium nitrate solution, 1.5mL concentrated ammonia water was added dropwise to the calcium nitrate solution, and then heated and stirred in a water bath at 70°C for 30min to obtain a calcium nitrate solution with a pH of 9; weigh 2.842g of Na 2 SiO 3 9H 2 O was dissolved in 100mL deionized water to obtain a sodium silicate solution, and the prepared sodium silicate solution was added dropwise to the calcium nitrate solution at a rate of 100mL / h, and mixed and stirred for 5 hours to obtain the first mixed solution; the first mixed solution was obtained by suction filtration The precipitate was obtained from the solution, and the precipitate was washed with deionized water, and then dried in a vacuum oven at 80°C for 8 hours to obtain a precursor powder; the precursor powder was calcined in ...

Embodiment 2

[0049] β-Ca 1.7 (Eu 0.1 Sr 0.2 ) SiO 4 Granular powder

[0050] The first step: weigh 2.362 grams of Ca (NO 3 ) 2 4H 2 Dissolve O in 100mL deionized water to prepare a calcium nitrate solution, add 1.5mL concentrated ammonia water dropwise, heat and stir in a water bath at 70°C for 30min to obtain a calcium nitrate solution with a pH of 7-8. Weigh 2.842 g Na 2 SiO 3 9H 2 O was dissolved in 100mL deionized water, and the prepared sodium silicate solution was added dropwise to the calcium nitrate solution at a rate of 100mL / h, mixed and stirred for 5h to obtain the first mixed solution; Get a precipitate from a mixed solution, wash the precipitate with deionized water, and then dry it in a normal pressure drying oven at 80°C for 8h to obtain a precursor powder; place the precursor powder in a microwave oven at 950°C for 0.5h and heat up The speed is 300°C / min, and naturally cooled to room temperature to obtain the intermediate product nano-calcium silicate powder.

[...

Embodiment 3

[0057] β-Ca 1.6 (Na 0.1 Sr 0.1 Fe 0.2 ) SiO 4 Granular powder

[0058] The first step: weigh 2.362 grams of Ca (NO 3 ) 2 4H 2 Dissolve O in 100mL deionized water to make a solution, add 1.5mL concentrated ammonia water dropwise, adjust the pH of the calcium nitrate aqueous solution to 8-9, heat and stir in a water bath at 70°C for 30min. Weigh 2.842 g Na 2 SiO 3 9H 2 O was dissolved in 100mL deionized water, and the prepared sodium silicate solution was added dropwise to the calcium nitrate solution at a rate of 50mL / h, heated and stirred in a water bath at 50°C for 8 hours to obtain the first mixed solution; centrifuge the first mixed solution The precipitate was obtained, washed with deionized water, placed in a freeze-drying oven, and dried for 12 hours through the steps of pre-freezing, sublimation, and desorption to obtain a precursor powder; the precursor powder was calcined in an infrared radiation furnace at 800°C 3h, the heating rate is 2000°C / min, and natu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Grain size | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap