An integrated internal bypass high-pressure low-torque opening and closing ball valve and its installation method

An internal bypass, low torque technology, used in valve devices, valve operation/release devices, lift valves, etc., can solve the problem that the valve seat seal is easily scratched and cannot continue to seal, and there is no way to overcome the high pressure difference and reduce valve usage. life and other issues, to achieve the effect of compact structure, simple structure and maintenance cost maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

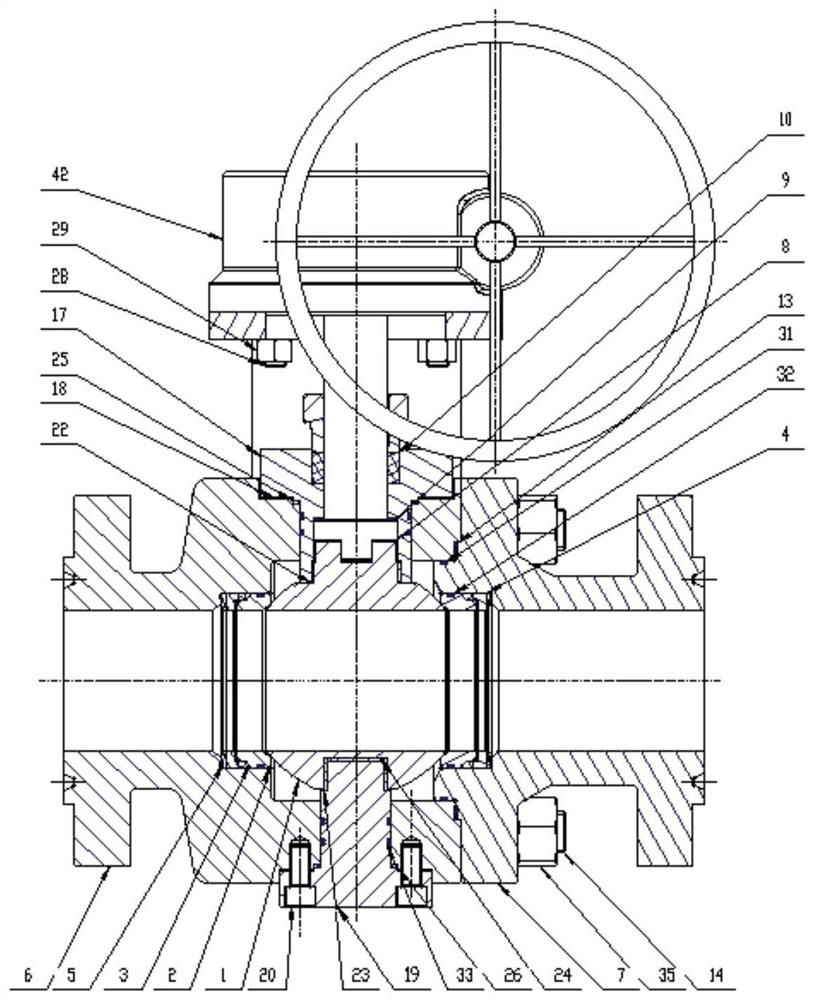

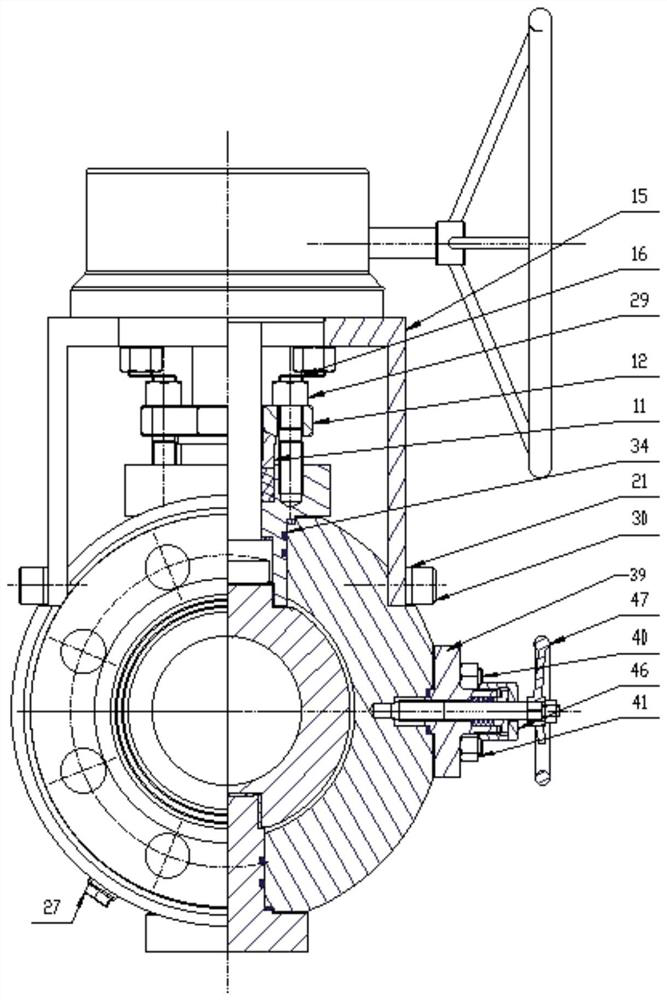

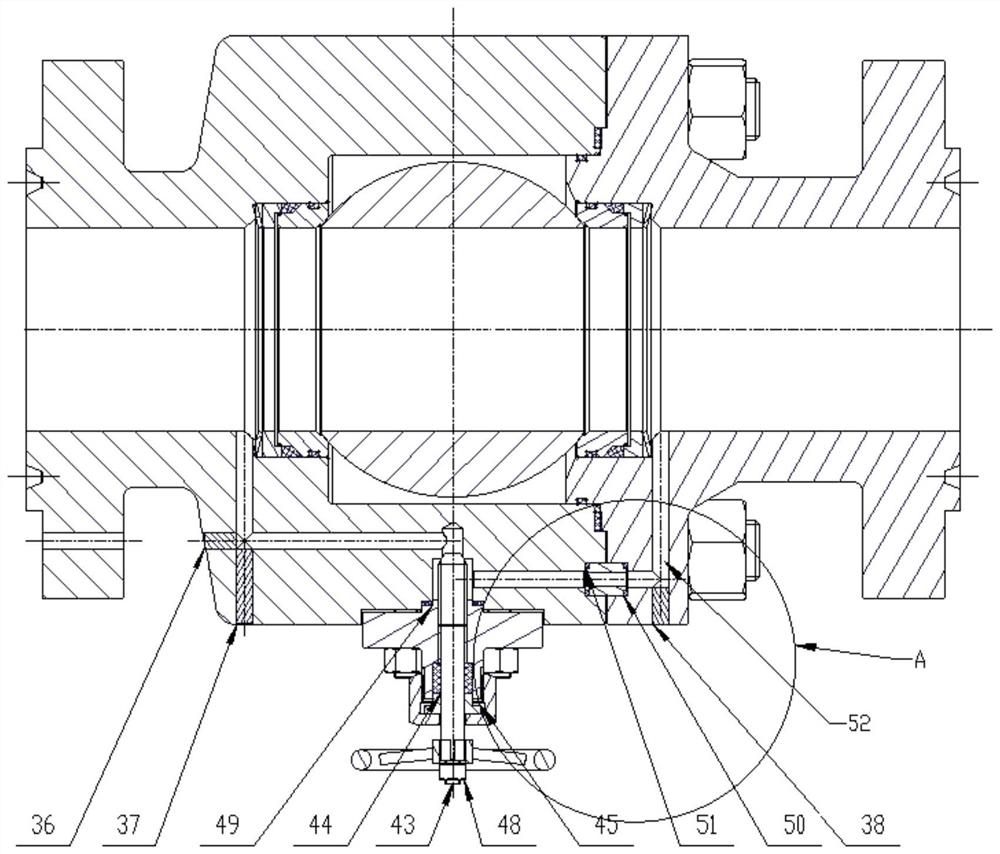

[0035] The implementation of the present application will be described in detail below with reference to the accompanying drawings and examples, so as to fully understand and implement the implementation process of how the present application uses technical means to solve technical problems and achieve technical effects.

[0036] Such as Figure 1-Figure 4 As shown, the integrated internal bypass high-pressure low-torque opening and closing ball valve and its installation method provided in this embodiment include a valve body 6, the valve body 6 includes a valve seat 2 and a valve cover 7, the valve seat 2 is integrally formed, and the valve One side of the seat 2 is fixedly provided with a hexagon bolt 27, and a manual wheel is provided for rotation on the worm reducer 42. The valve body 6 and the valve cover 7 are fixedly connected by the first stud 14, and the first stud 14 is screwed and connected with a second screw. Two nuts 35, the first stud 14 is rotatably connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com