Energy-saving type trolley for resistance furnace

A resistance furnace and trolley technology, applied in the field of heat treatment of rolls, can solve the problems of power consumption, excessive weight, and increased production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

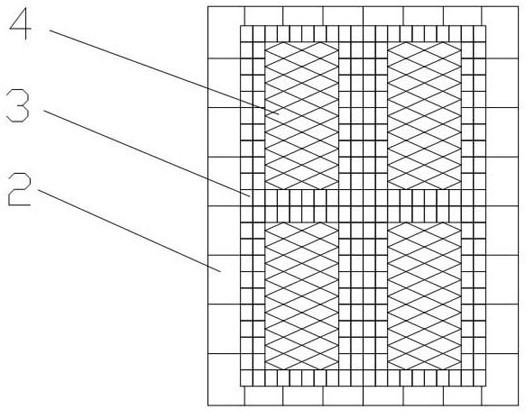

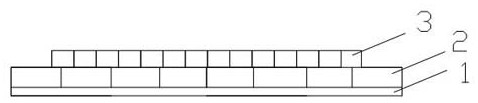

[0015] like Figure 1~2 The resistance furnace energy-saving trolley shown includes a bearing platform 1, on which a layer of No. 1 insulation brick 2 is laid, and the No. 1 insulation brick 2 is laid to form a rectangle; No. 2 thermal insulation brick 3 and thermal insulation asbestos 4, the No. 2 thermal insulation brick 3 is laid into a shape with several cavities in the middle, and the cavity is filled with thermal insulation asbestos 4, No. 2 thermal insulation brick 3 and thermal insulation asbestos 4 are laid in the shape It is also rectangular; the area of the rectangle formed by the No. 1 thermal insulation brick 2 is larger than the rectangle formed by the No. 2 thermal insulation brick 3 and thermal insulation asbestos 4, and the rectangle formed by the No. The rectangular projection formed by the insulation brick 2 is covered by the rectangle formed by the No. 1 insulation brick 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com