Winding device for transformer core

A transformer core and winding technology, applied in the field of transformers, can solve the problems of poor winding insulation, loose core installation, noise pollution, etc., and achieve the effects of good winding insulation, less noise generated by device vibration, and long service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

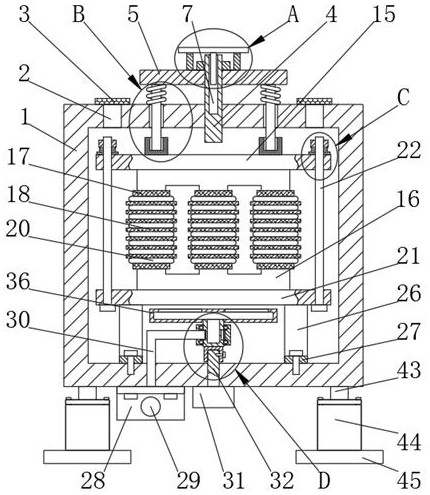

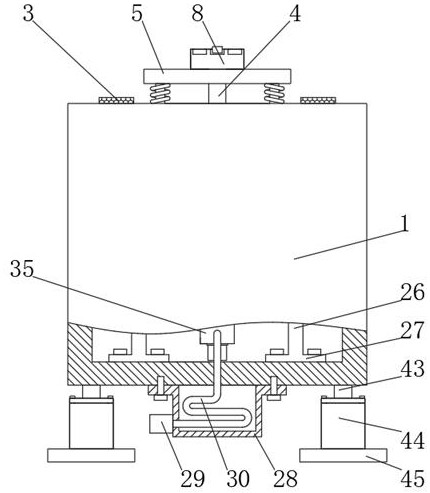

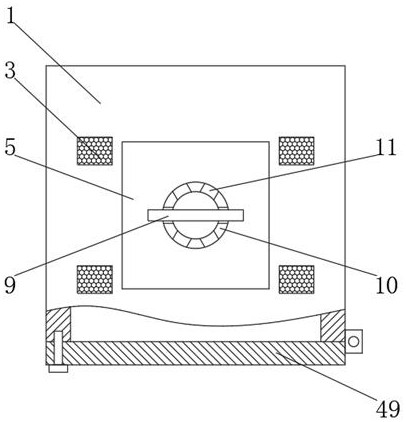

[0033]A winding device for a transformer core, including a casing 1, the upper end of the casing 1 is provided with a cooling hole 2, and the upper end of the casing 1 is threaded with a threaded rod 4, and the outer side of the threaded rod 4 Slidingly sleeved with a pressure plate 5, a square hole 7 is provided in the threaded rod 4, a square rod 8 is slidably connected in the square hole 7, and a cross bar 9 is welded on the upper end of the square rod 8. The upper end is welded with a support sleeve 10, and the upper end of the support sleeve 10 is provided with a card slot 11, and a cross bar 9 is slidably connected to the inside of the card slot 11. There are a plurality of the card slots 11, and the plurality of the card slots 11 are uniform. Distributed on the upper end of the support sleeve 10, the lower end of the pressure plate 5 is welded with a pressure rod 12, the pressure rod 12 has four, and the four pressure rods 12 are evenly distributed on the lower end of th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap