Seedling combined grafting device and method

A grafting device and technology for seedlings, applied in the field of agronomic tools, can solve problems such as difficulty in ensuring good butt jointing of scion and rootstock incisions, effective docking and fixing of difficult incision positions, complicated and delicate operations, etc. The effect of high rate and sufficient nutrient absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

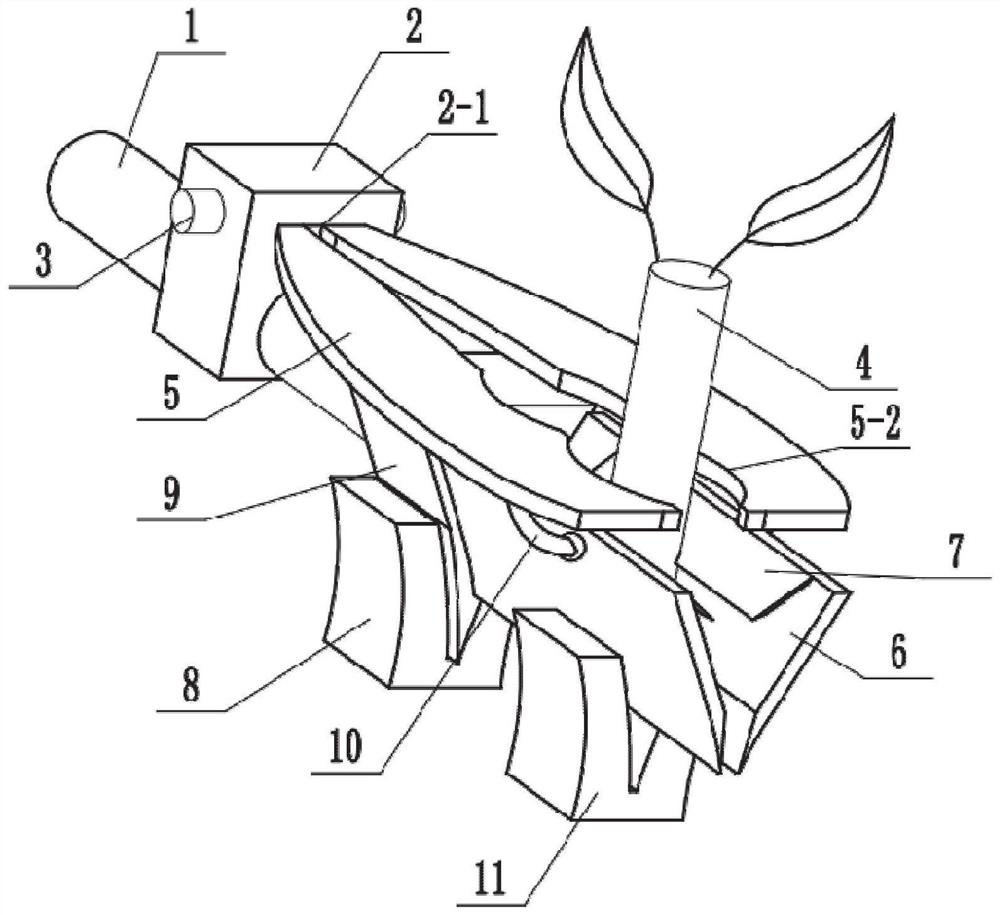

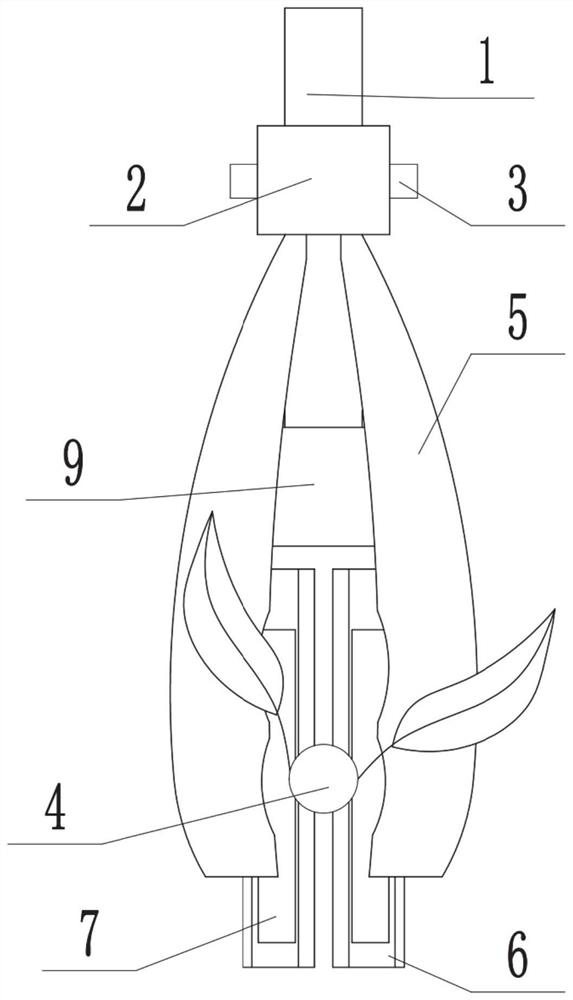

[0039] In a typical implementation of the present disclosure, such as Figure 1-Figure 7 As shown, a seedling combination grafting device is proposed.

[0040] It mainly includes a hand-held rod, a fixture box, a fixture, a main cutter and a separation knife, wherein the hand-held rod is used as the grip part of the operator and also as the frame of the entire grafting device; during the grafting process, the scion is the fruiting seedling, and the rootstock is the antibody seedlings;

[0041] The fixture is hinged on the fixture box, the fixture box is installed on the handle bar, the main cutter is installed on one end of the handle bar, the separation knife is installed on the main cutter through the rotating pair, and its working state can be changed by rotating around the rotating pair.

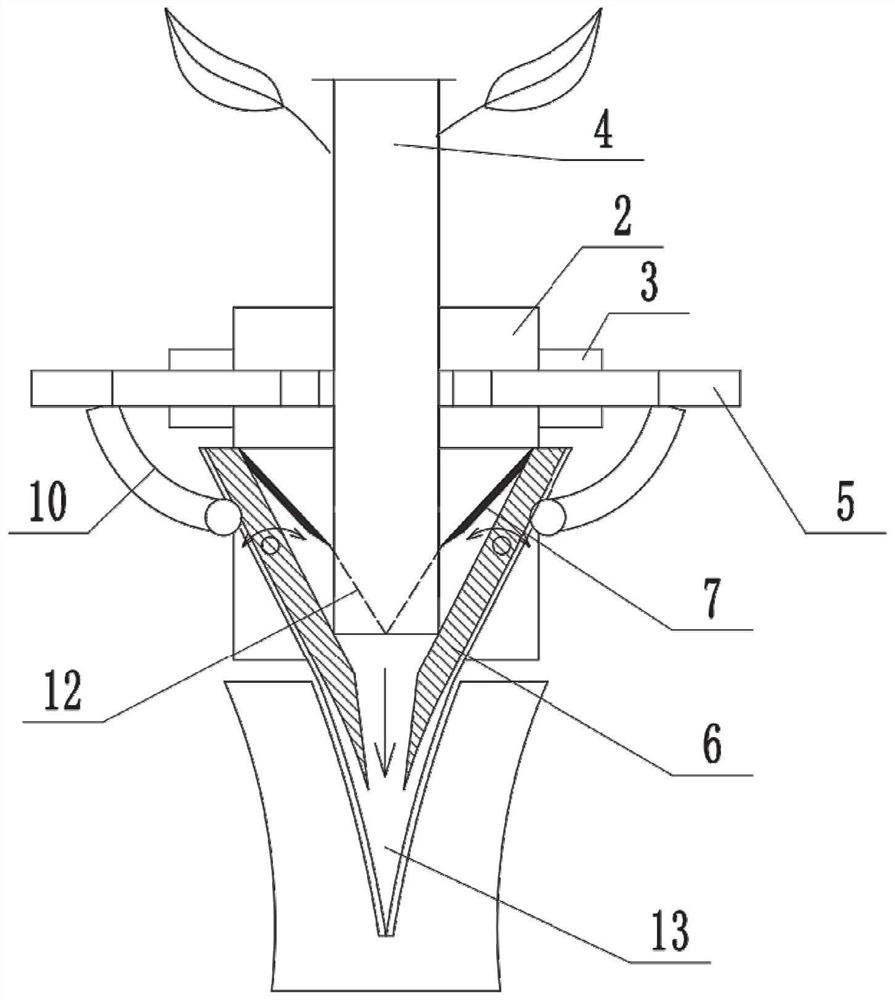

[0042] Specifically, the clamp includes two clamping plates oppositely arranged and hinged at the ends. The two separating knives are respectively connected to one end of the main cutti...

Embodiment 2

[0063] In another typical implementation of the present disclosure, such as Figure 1-Figure 7 Shown, provide a kind of seedling combination grafting method, utilize the seedling combination grafting device as in embodiment 1.

[0064] Include the following steps:

[0065] The clamping part cooperates with clamping the scion, pushing the action of the splint to drive the separation knife to rotate;

[0066] The cutting knife arranged on the separating knife obliquely cuts the end of the scion to form an incision, and the ends of the two separating knives move closer;

[0067] The main cutter cuts the rootstock to form an incision, and under the action of the hand-held rod, the main cutter is driven to gradually separate from the rootstock incision, so that the separation knife touches the rootstock incision;

[0068] When the incision of the scion corresponds to the incision of the rootstock, the splint opens to drive the separation knife to expand the incision of the stock,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com