Method for preparing vegetarian meat by using soybean protein isolate

A technology of soybean protein isolate and vegetarian meat, which is applied in the protein composition of vegetable seeds, protein food processing, plant protein processing, etc., can solve the problem of unsatisfactory texture, taste, smell and color of vegetarian meat products that cannot satisfy consumers. Few researches on simulated meat products and vegetarian meat preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

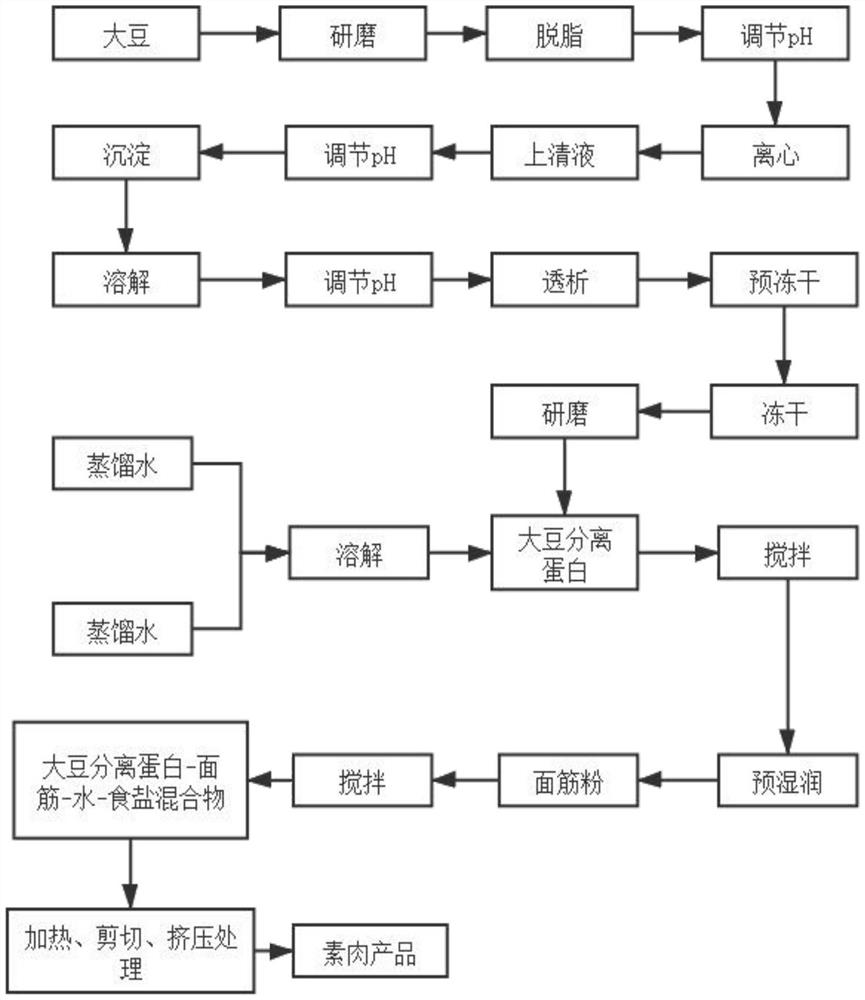

Image

Examples

Embodiment 1

[0013] Grind soybeans into soybean powder and degrease the soybean powder with n-hexane at a ratio of 1:3 (w / v) for 3 times. After degreasing, remove n-hexane in a fume hood. (w / w) was dissolved in distilled water, adjusted to pH 8.5 with 2M NaOH, and mechanically stirred at 27°C for 2h, then centrifuged at 9000×g for 20min, the supernatant was collected and adjusted to pH 4.5 with 2M HCl, and then stirred at 6000×g Centrifuge at g for 15min, discard the supernatant, dissolve the precipitate in distilled water, neutralize the pH to 7.0 with 2M NaOH, dialyze with distilled water at 4°C for 24h, then pre-freeze at -40°C and freeze-dry, grind to obtain soybean isolate Protein powder for later use; (2) Mix 68% (w / w) of distilled water and 2% (w / w) of salt in a blender, add 20% (w / w) of soybean protein isolate to the blender and mix After 10 minutes, the obtained soybean protein-water-salt mixture was kept in a mixer for 30 minutes for pre-wetting. Add 10% (w / w) gluten flour to th...

Embodiment 2

[0015] Grind soybeans into soybean powder and degrease the soybean powder with n-hexane at a ratio of 1:3 (w / v) for 3 times. After degreasing, remove n-hexane in a fume hood. (w / w) was dissolved in distilled water, adjusted to pH 8.5 with 2M NaOH, and mechanically stirred at 27°C for 2h, then centrifuged at 9000×g for 20min, the supernatant was collected and adjusted to pH 4.5 with 2M HCl, and then stirred at 6000×g Centrifuge at g for 15min, discard the supernatant, dissolve the precipitate in distilled water, neutralize the pH to 7.0 with 2M NaOH, dialyze with distilled water at 4°C for 24h, then pre-freeze at -40°C and freeze-dry, grind to obtain soybean isolate Protein powder ready for use. (2) 68.5% (w / w) of distilled water and 1.5% (w / w) of salt were mixed evenly and placed in a blender, and 21% (w / w) of soybean protein isolate was added to the blender and mixed for 10 minutes to obtain The soy protein-water-salt mixture was kept in the blender for 30 min for pre-moiste...

Embodiment 3

[0017] Grind soybeans into soybean powder and degrease the soybean powder with n-hexane at a ratio of 1:3 (w / v) for 3 times. After degreasing, remove n-hexane in a fume hood. (w / w) was dissolved in distilled water, adjusted to pH 8.5 with 2M NaOH, and mechanically stirred at 27°C for 2h, then centrifuged at 9000×g for 20min, the supernatant was collected and adjusted to pH 4.5 with 2M HCl, and then stirred at 6000×g Centrifuge at g for 15min, discard the supernatant, dissolve the precipitate in distilled water, neutralize the pH to 7.0 with 2M NaOH, dialyze with distilled water at 4°C for 24h, then pre-freeze at -40°C and freeze-dry, grind to obtain soybean isolate Protein powder ready for use. (2) 69% (w / w) of distilled water and 1% (w / w) of salt were mixed evenly and placed in a blender, and 23% (w / w) of soybean protein isolate was added to the blender and mixed for 10 minutes to obtain The soy protein-water-salt mixture was kept in the blender for 30 min for pre-moistening...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com