Process method for controlling surface defect of flanged ridge R of tail lamp of side wall outer plate

A process method and rear taillight technology, which is applied in the direction of manufacturing tools, forming tools, metal processing equipment, etc., can solve the problems such as irregularity and unevenness of the edge line R of the flanging, and reduce the number of rounds of rectification of the later parts, so as to achieve the guarantee The effect of forming quality, shortening the rectification period, and solving surface defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

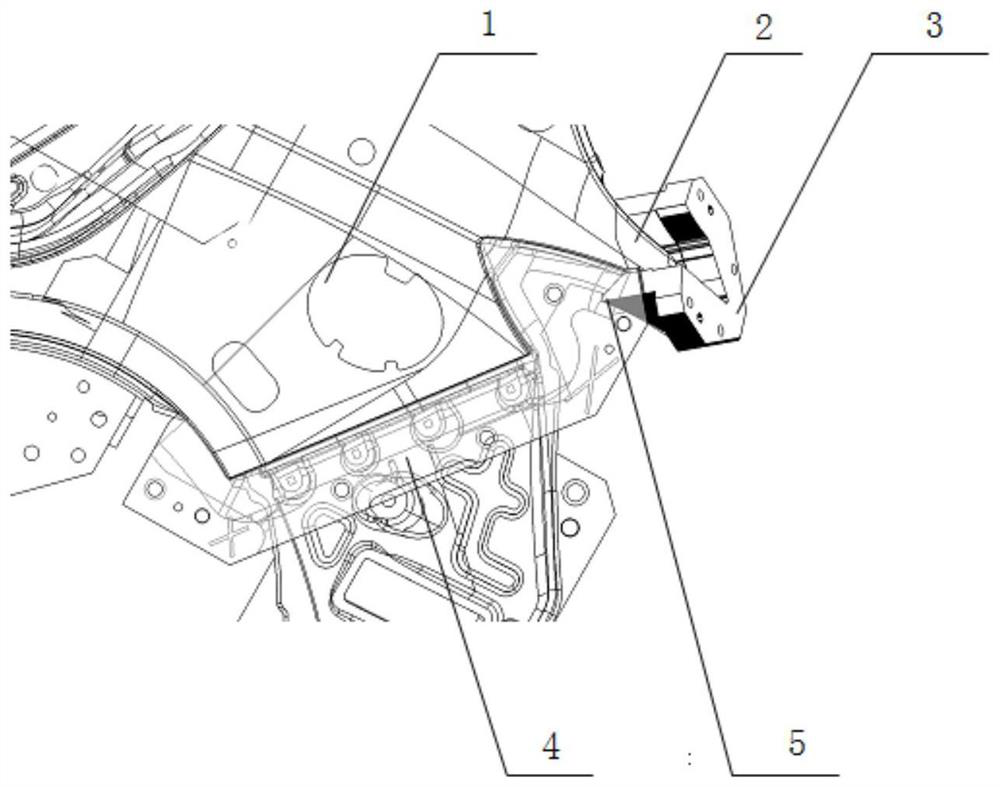

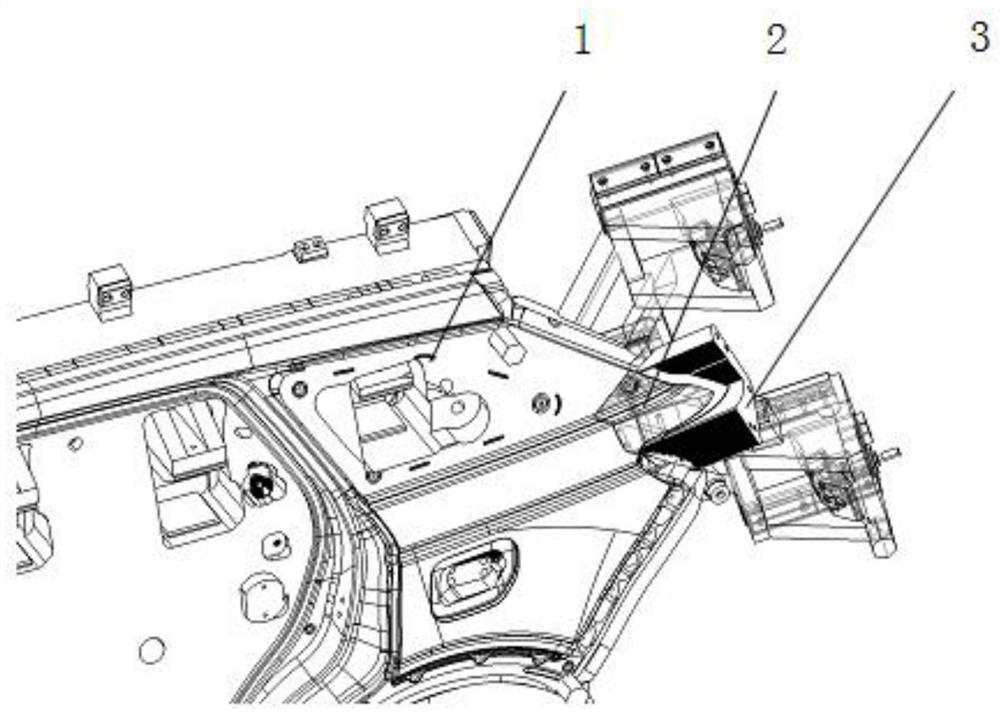

[0047] The invention is a process method for controlling the surface defects of the edge line R of the flange of the rear taillight of the side wall outer panel, and solves the problem that the edge line R of the flange is not smooth caused by the flange connecting knife and multi-material flange. The invention can not only ensure the forming quality of the parts in the production process, reduce the process risk caused by the flanging and joining of knives, solve the surface defects such as R irregularities, but also effectively reduce the number of rounds of rectification of the later parts.

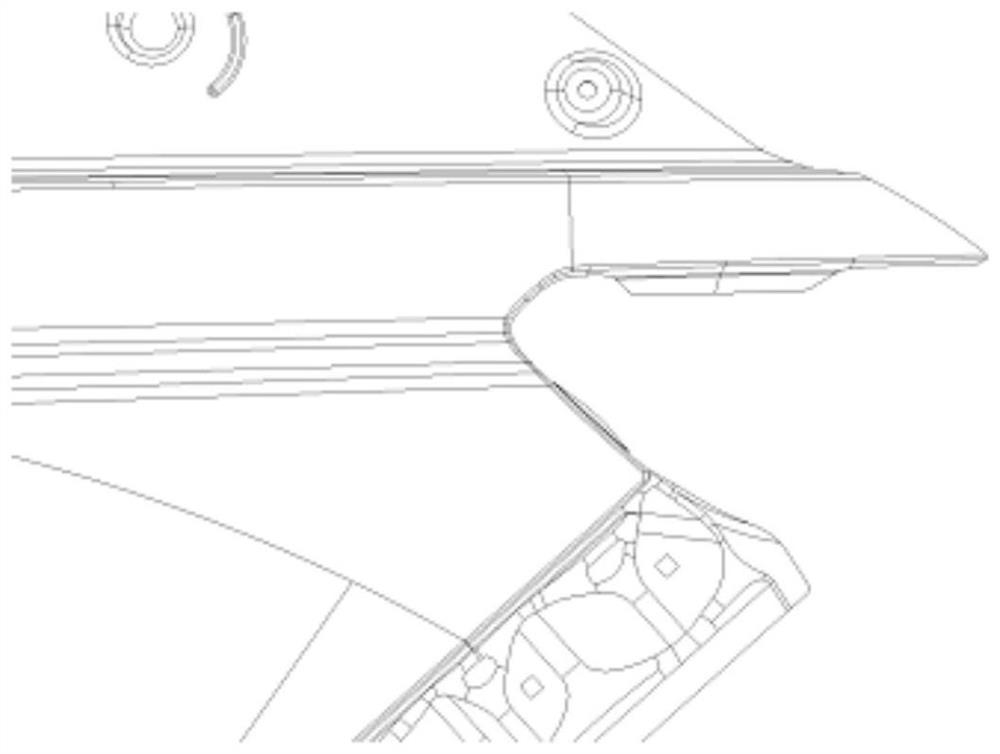

[0048] The technical solution of the present invention is: a process method for controlling the surface defects of the rear taillight flange R of the side wall outer panel, such as figure 1As shown, the rear taillight area of the side wall outer panel overlaps with the rear taillight of the exterior trim, and this area is the first-level visible area of the vehicle, so the surface q...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com