Pressure-resistant release film

A release film and release agent technology, applied in the direction of layered products, synthetic resin layered products, chemical instruments and methods, etc., can solve the problems of limited external force, limited external pressure, and limited deformation of the tough inner layer. Achieve good cushioning capacity and good compression performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific implementation manner of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

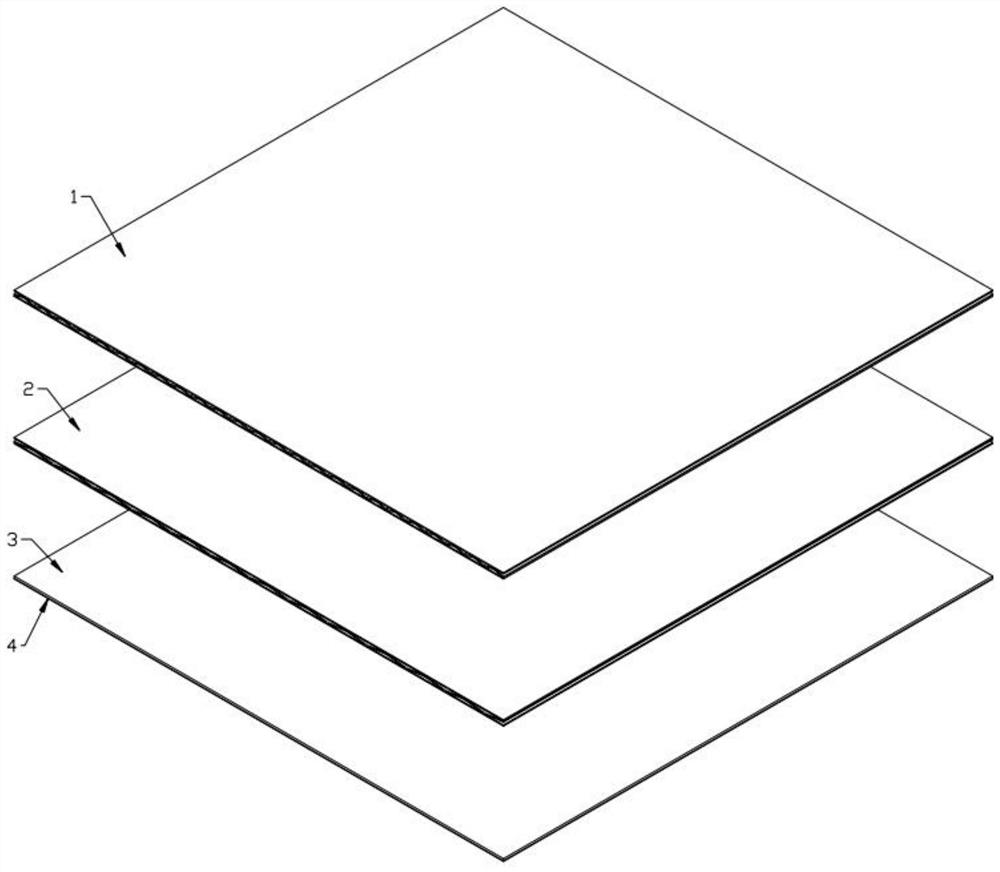

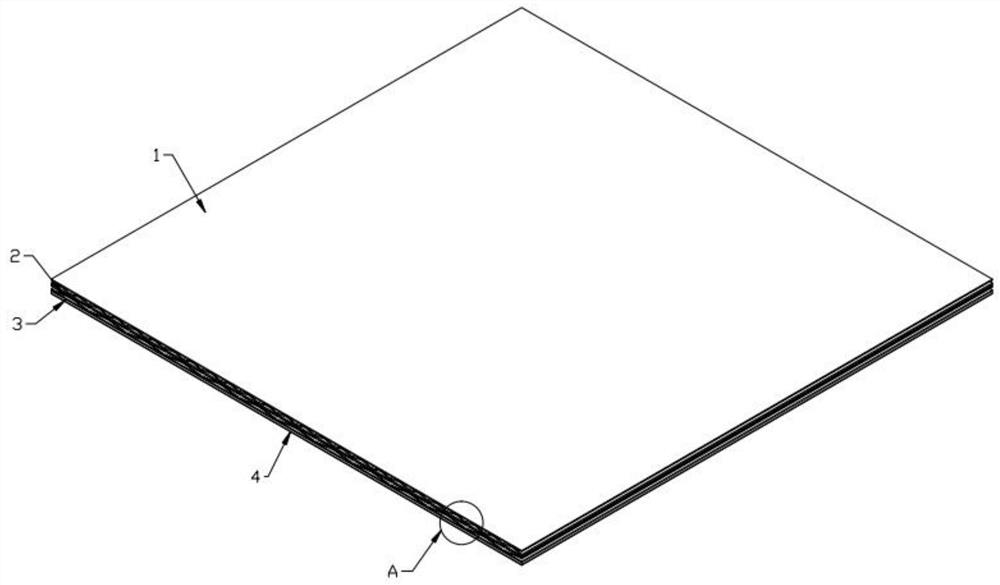

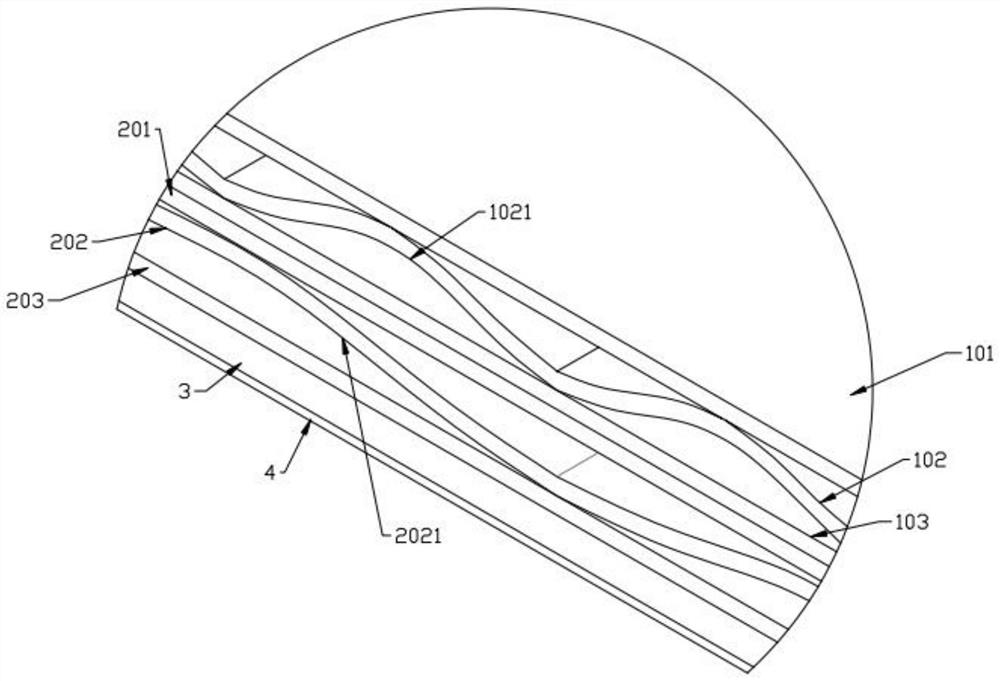

[0026] Such as Figures 1 to 3 As shown, the pressure-resistant release film includes a base layer 3, the base layer 3 provides support for the release film as a whole, one side of the base layer 3 is provided with a release agent coating 4, and the other side of the base layer 3 is provided with a second buffer Layer 2, the side of the second buffer layer 2 that is away from the base layer 3 is provided with a first buffer layer 1; the inside of the first buffer layer 1 is provided with a first corrugated layer 102, and the first corrugated layer 102 has a number of evenly arranged The first corrugated 1021 of the second buffer layer 2 is provided with a second corrugated layer 202, the second corrugated layer 202 has a number of evenly arranged second corrugated 2021; the width of the first corrugated 1021 is not ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com