High-precision automatic printing machine for circuit board production

A circuit board, high-precision technology, applied to printing machines, rotary printing machines, screen printing machines, etc., can solve the problems of discontinuous printing process, long waiting time for operators, low work efficiency, etc., to avoid printing failure, Make up for unskilled devices and operations, and reduce the effect of manual steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

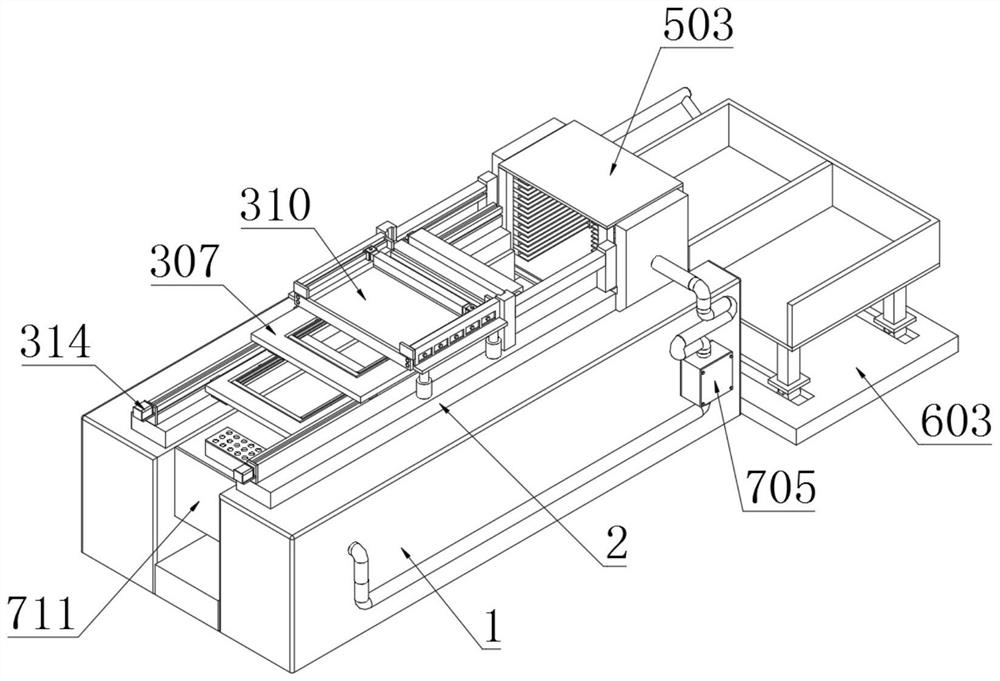

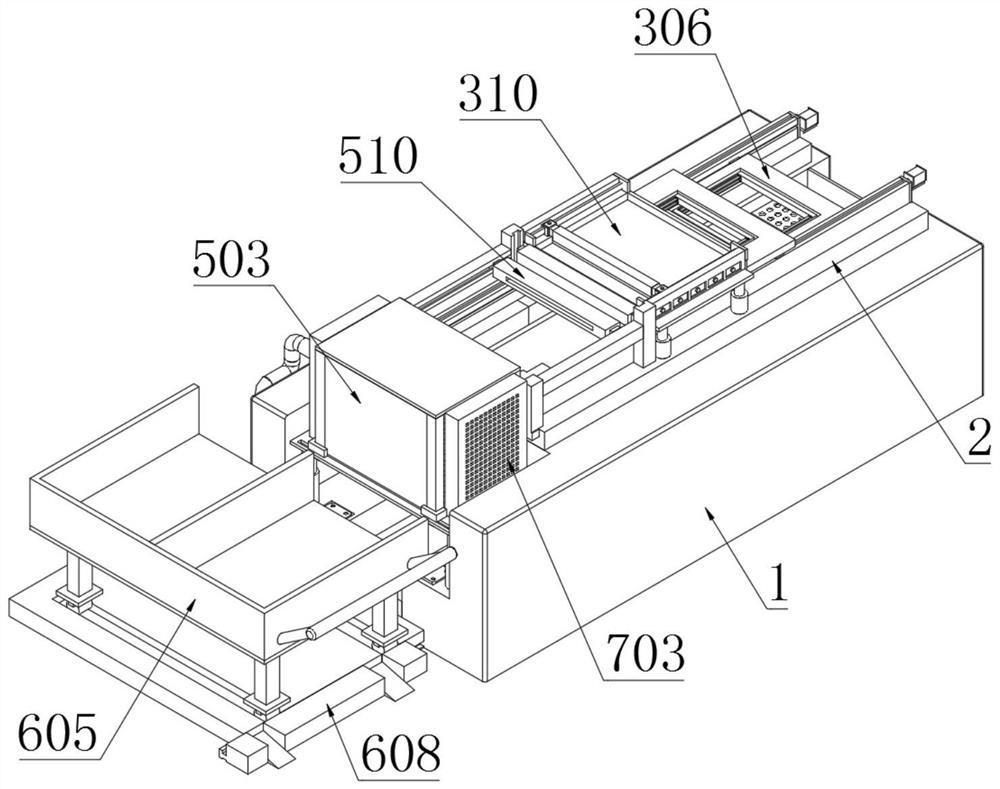

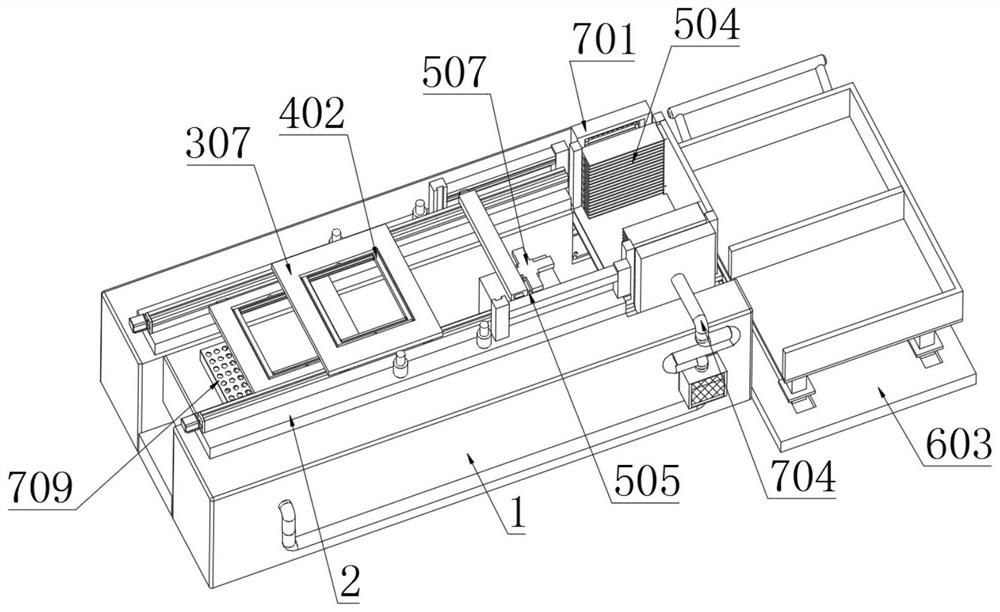

[0046] Example: such as Figure 1-9 As shown, the present invention provides a technical solution, a high-precision automatic printing machine for circuit board production, including a processing base 1, the top of the processing base 1 is symmetrically fixed with a strip base 2, and the top of the strip base 2 is fixed A high-efficiency continuous printing mechanism 3 is installed, so that the two circuit boards can move in a different position, and print at a staggered time to reduce the waste of time;

[0047] The middle part of the high-efficiency continuous printing mechanism 3 is fixed with a convenient steering mechanism 4, so that the direction of the circuit board can be automatically reversed, and continuous double-sided printing can be performed;

[0048] The top of the processing base 1 is located on one side of the high-efficiency continuous printing mechanism 3, and an automatic unloading mechanism 5 is fixedly installed, which automatically removes the circuit b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com