Steamed non-fired foamed ceramic insulation board for building

A technology of foamed ceramics and thermal insulation boards, which is applied in the field of building materials, can solve the problems of energy consumption, high manufacturing cost of foamed ceramic thermal insulation boards, unfavorable development direction of energy-saving and low-carbon management technology, and achieve low manufacturing costs, excellent thermal insulation and Fire performance, energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Example 1: see figure 1 As shown, a foamed ceramic thermal insulation board for a steam-free building includes a non-fired foamed ceramic thermal insulation board base 10 formed by a foaming process, and the unfired foamed ceramic thermal insulation board base 10 includes the following raw materials in parts by weight:

[0034]

[0035]

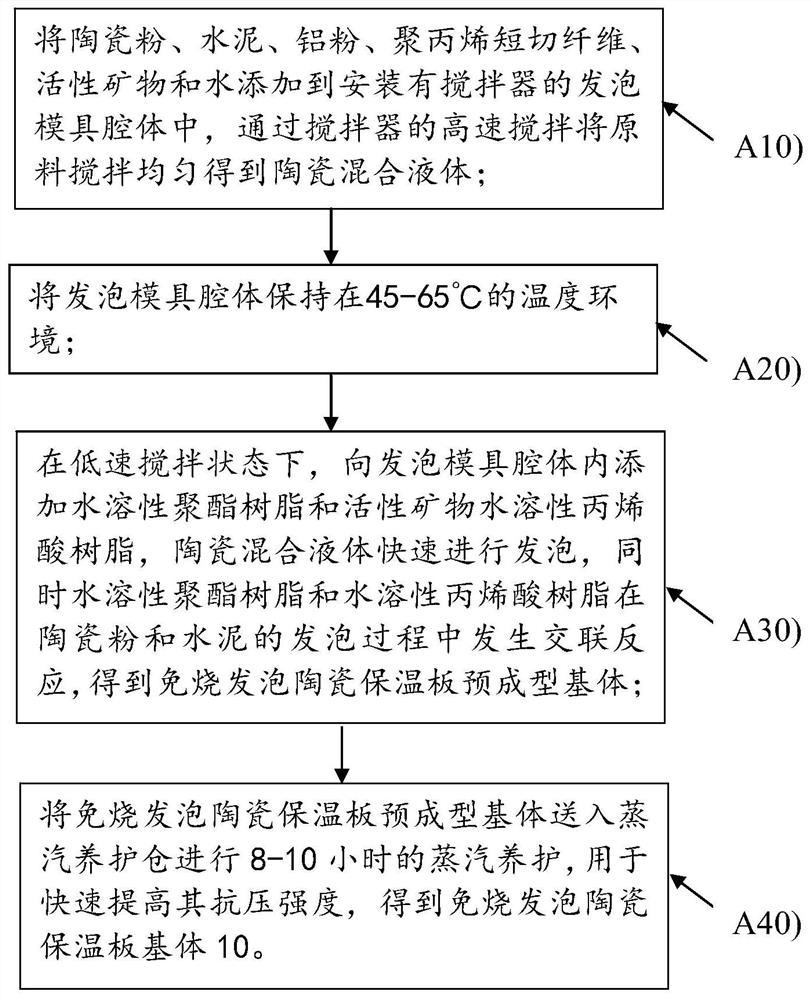

[0036] see further figure 2 As shown, in this embodiment, the preparation process of the non-fired foamed ceramic insulation board base 10 includes the following steps:

[0037] A10), ceramic powder, cement, aluminum powder, polypropylene chopped fibers, active minerals and water are added to the foaming mold cavity equipped with a stirrer, and the raw materials are stirred evenly by the high-speed stirring of the stirrer to obtain a ceramic mixed liquid , preferably, in this step A10), the speed of high-speed stirring is not less than 600 rpm, and the stirring time is not less than 10 minutes, specifically 800 rpm, and the sti...

Embodiment 2

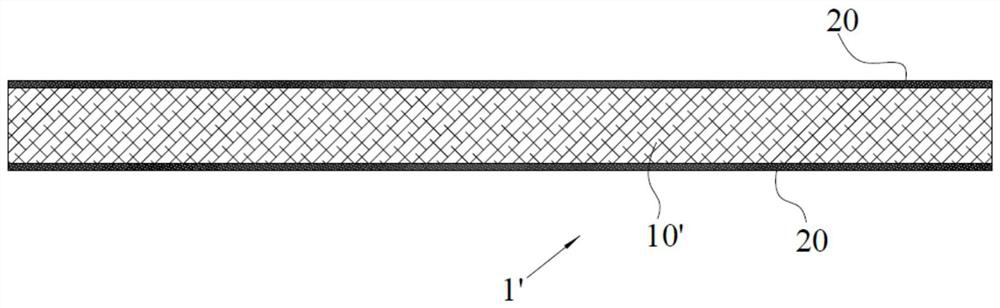

[0041]Embodiment 2: The remaining technical solutions of this embodiment 2 are the same as those of embodiment 1, the difference is that please refer to image 3 As shown, the present embodiment 2 proposes a kind of foamed ceramic thermal insulation board 1' for a steam-free building, and its base 10' of a non-fired foamed ceramic thermal insulation board includes the following raw materials in parts by weight:

[0042]

[0043] In this embodiment, a surface enhancer is used to perform penetration-enhancing coating treatment on the surface of the non-fired foamed ceramic heat preservation board base 10 ′, which is used to form a layer of hydrophobic protective film on the surface of the unfired foamed ceramic heat preservation board base 10 ′; Preferably, in this embodiment, the surface enhancer is a silicone penetrating waterproofing agent, and the silicone penetrating waterproofing agent is coated on the surface of the foamed ceramic insulation board substrate 10' and unde...

Embodiment 3

[0050] Embodiment 3: the remaining technical solutions of this embodiment 3 are the same as those of embodiment 1, the difference is that this embodiment 3 proposes a foamed ceramic insulation board for steam-free construction, and its foamed ceramic insulation board base includes the following parts by weight Number of raw materials:

[0051]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap