Big data-based storage-cleaning reaction tank, storage tank or fermentation tank with groove, and big data-based storage-cleaning method

A technology of big data and reaction tank, which is applied in the direction of specific-purpose bioreactor/fermenter, combination of bioreactor/fermenter, biochemical equipment and methods, etc. It can solve the problems of high internal temperature, high oil tank and accident-prone Falls and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

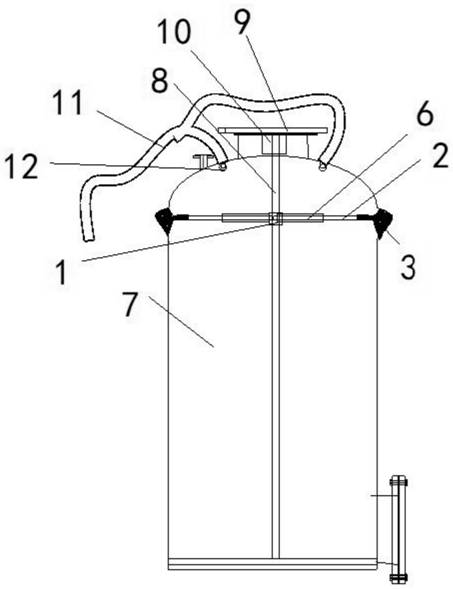

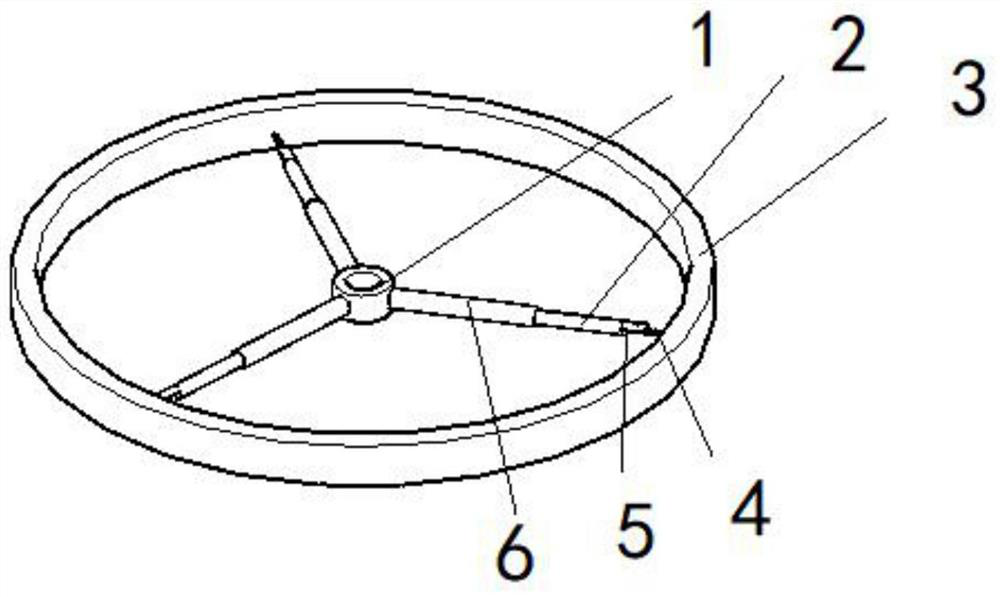

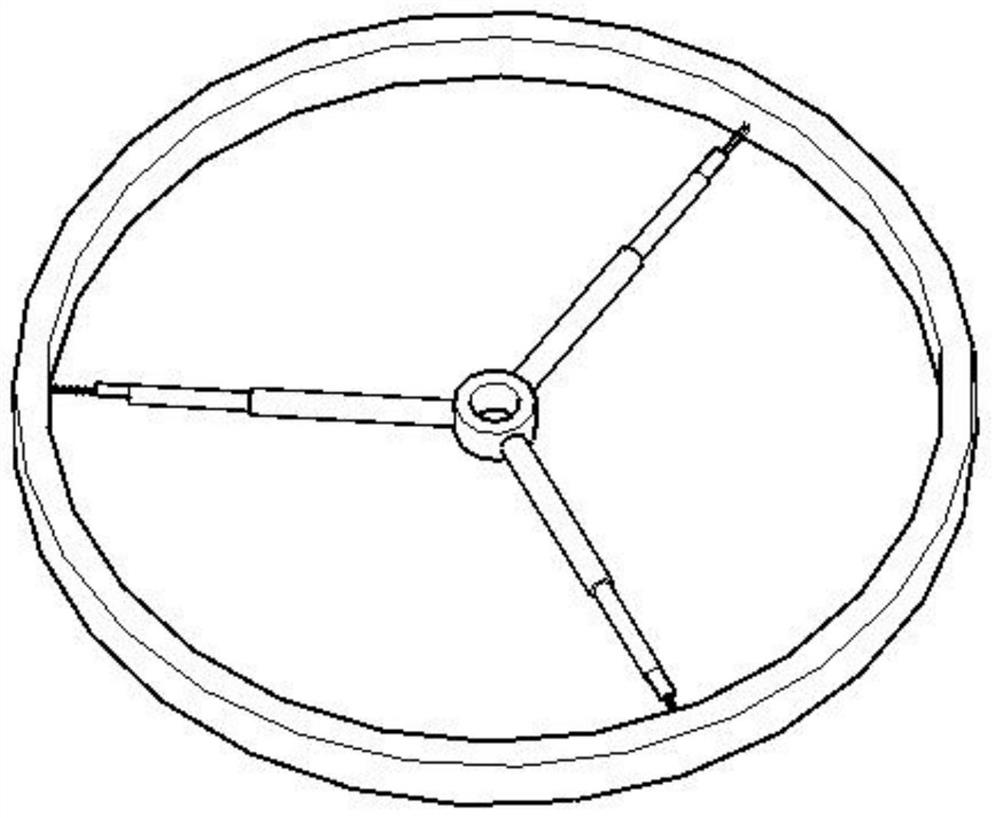

[0039] Example 1: Combining figure 1 and figure 2 ; Based on big data, the grooved clear storage reaction tank storage tank or fermenter is characterized in that it comprises a tank body, and the middle part of the tank body includes a vertically arranged middle threaded shaft 8, which can be over-rotated , the lower part of the threaded shaft in the middle is installed through a bearing, and the upper part of the threaded shaft 8 is fixedly connected to the power output shaft of the upper motor and its reducer 10. The upper motor is a forward and reverse motor, and a threaded collar 1 is installed on the middle threaded shaft. The threaded ferrule 1 is fixedly connected to the connection part, the connection part is fixedly connected to the spring 4, and the end of the spring 4 is fixedly connected to the extruded end head 3, which is a rubber cleaning ring;

[0040] The threaded shaft in the middle drives the threaded ferrule 1 and the extrusion end head 3 to move up and d...

Embodiment 2

[0047] Embodiment 2: As a further improved solution or a side-by-side solution or an optional independent solution, the middle part of the section of the extruded end head 3 is thicker, and the lower part is thinner. The substantive technical effect played by the technical solution here and its realization process are as follows: figure 1 , it can move up and down conveniently, and this cross-sectional shape can facilitate the cleaning of the inner wall of the tank.

Embodiment 3

[0048] Embodiment 3: As a further improved solution or a side-by-side solution or an optional independent solution, the air cylinder is a remote control air cylinder; a sensor is installed on the threaded collar downwards, and the sensor is a height sensor or a temperature sensor. The substantive technical effect and the realization process of the technical solution here are as follows: As a further preference, a pressure sensor is arranged at the end of the spring, and the pressure sensor can be remotely communicated to the central control system, so by adjusting the pressure sensor of the cylinder The degree of expansion and contraction can further adjust the extrusion force and further adjust the cleaning pressure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com