Side surface protection device for blocked pressure gauge

A protective device and type pressure gauge technology, which is applied in the direction of measurement, wellbore/well components, earthwork drilling and production, etc., can solve the problems of inability to disassemble twice, inconvenient maintenance of instruments, etc., achieve simple structure, convenient installation and use, and solve problems that cannot be solved The effect of individual maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

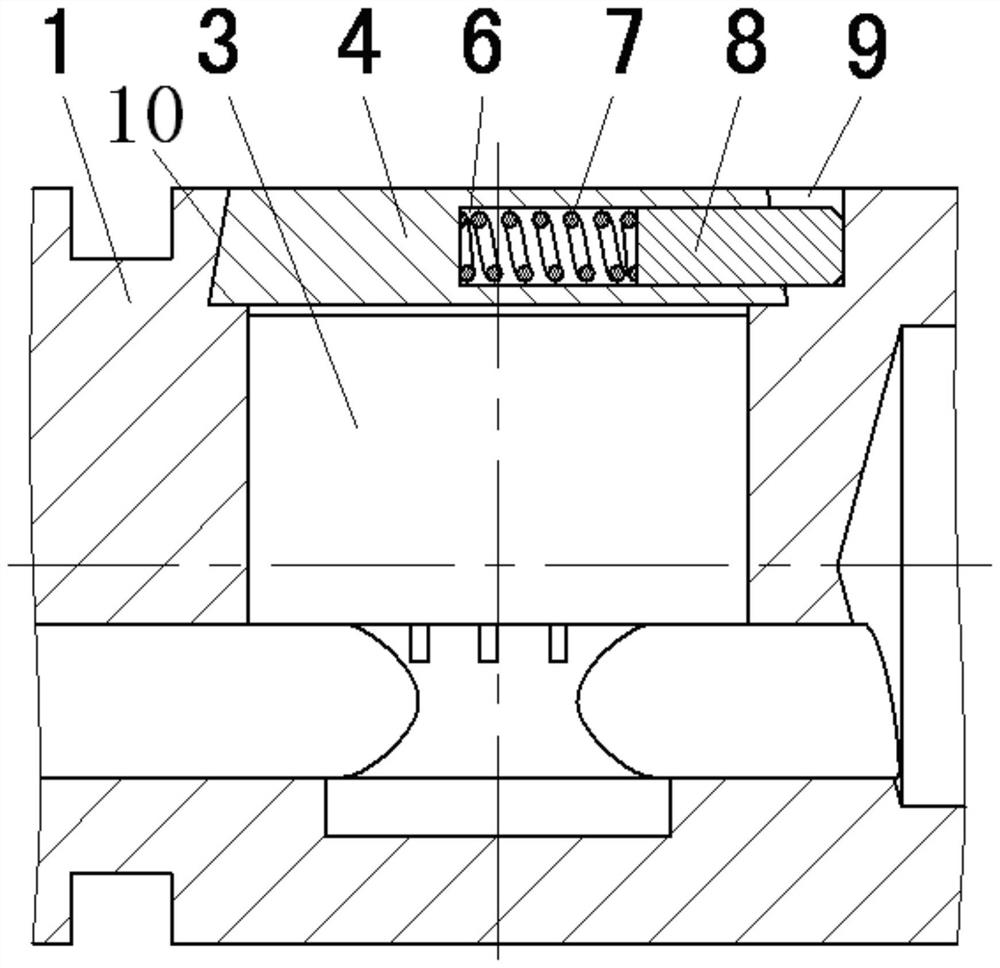

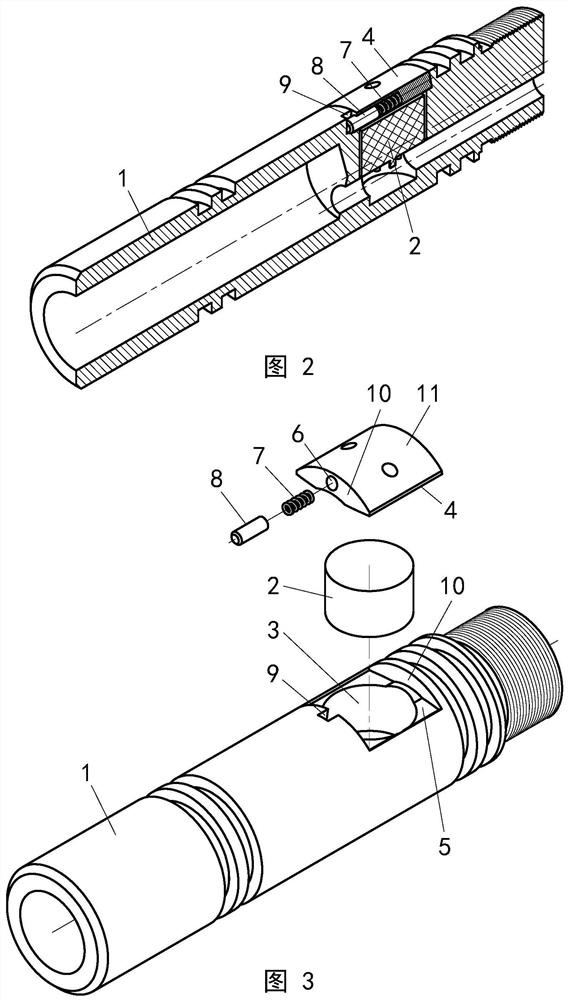

[0014] A side protection device for a plugging pressure gauge of the present invention, such as Figure 1 ~ Figure 3 As shown, the device includes an instrument body 1; the instrument body 1 is provided with a circular cavity 3 for placing the pressure sensor 2, and the top of the circular cavity 3 is provided with a protective cover 4; the mouth of the circular cavity 3 is provided with a The cover plate groove 5 corresponding to the shape of the protective cover plate 4; one end of the protective cover plate 4 is provided with a blind hole 6, and a spring 7 and a limit pin 8 are arranged in the blind hole 6; Limit pin groove 9. Between the two ends of the instrument body 1 and the protective cover 4 is an embedded fitting structure of a slope 10 . The top surface of the protective cover plate 4 is an arc surface 11 with the same radius as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com