Hydraulic slide valve internal leakage acoustic emission detection experiment device and using method thereof

A technology of acoustic emission detection and experimental equipment, which is applied in the direction of fluid pressure actuation device, fluid pressure actuation system test, fluid pressure actuation system components, etc., and can solve problems such as staying in theoretical research

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The invention will be described in detail below in conjunction with specific embodiments.

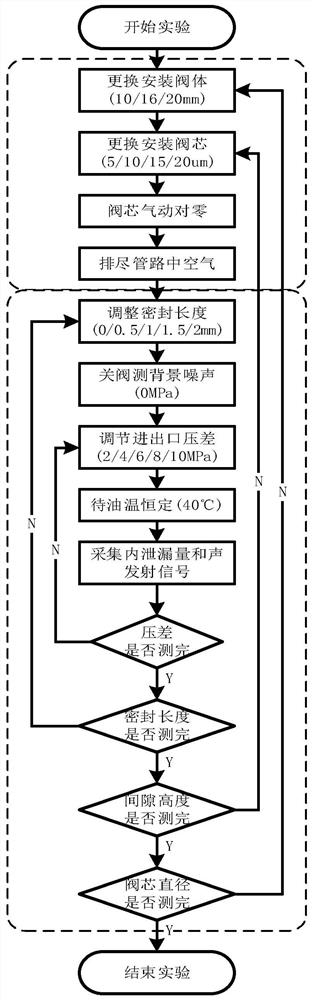

[0046] This application relates to an experimental device for acoustic emission detection of internal leakage of a hydraulic slide valve, which is mainly used to simulate the leakage state of the hydraulic slide valve during the working process, and conduct acoustic emission detection of the leakage situation under different parameters and conditions, so as to facilitate teaching and learning. Experiments help users or students to connect the leakage principle and characteristics of the hydraulic slide valve more intuitively, master the principle of acoustic emission detection technology and the specific operation process, and display the theoretical research content in a visible, audible and operable way, while achieving reproducible and reproducible Practical instruction for adjusting parameter settings.

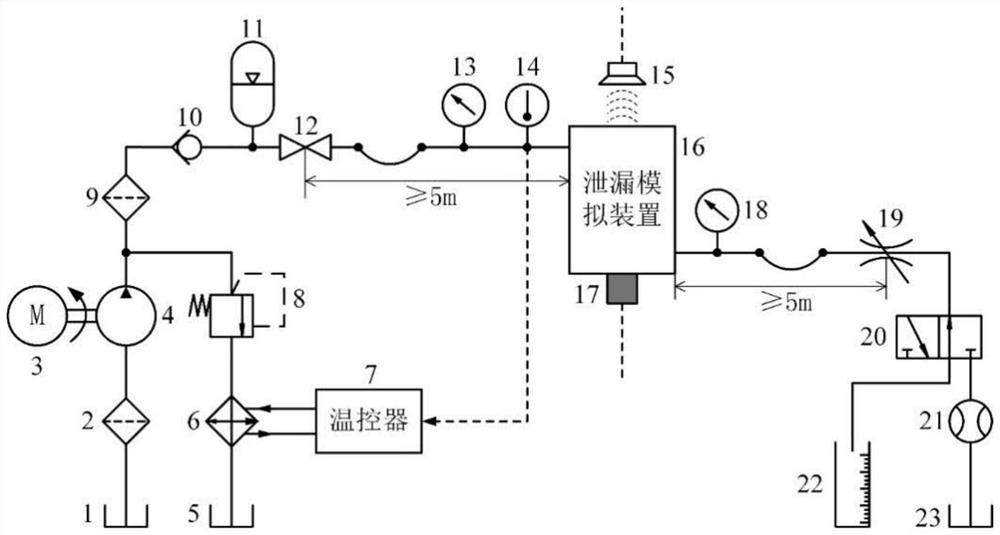

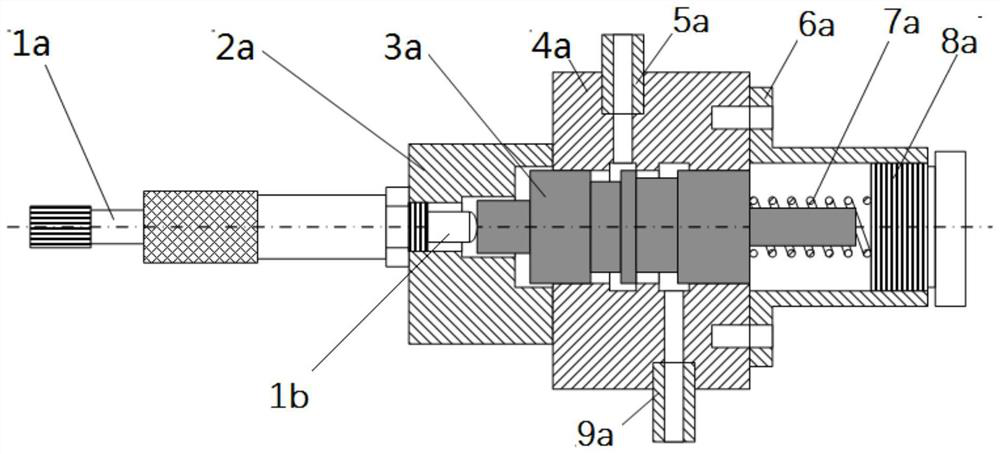

[0047] Such as figure 1 , figure 2 As shown, the basic structure of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com