Liquid level detection system and method, computer equipment and storage medium

A liquid level detection and liquid level technology, applied in the field of data processing, can solve the problems of inaccurate liquid level data, liquid level sensor measurement data error, etc., to achieve accurate liquid level information and reduce measurement errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

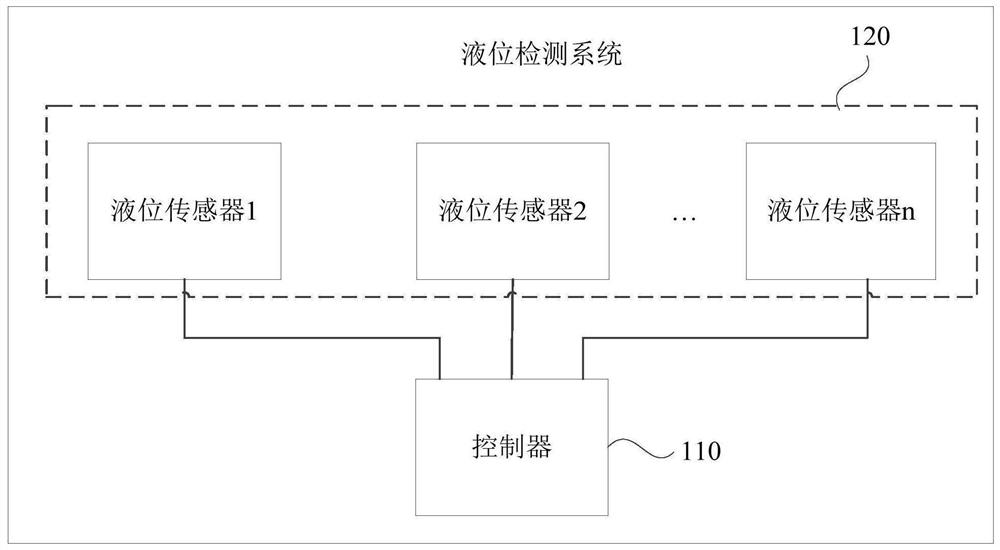

[0026] figure 1 Is a schematic structure of a liquid level detecting system according to a first embodiment of the present invention, embodiments applicable to a case of detecting the level value of the level detection region according to the present embodiment, the system comprising: a plurality of level sensor 110 and a controller 120 the controller 110 are connected to the respective level sensor 120, wherein:

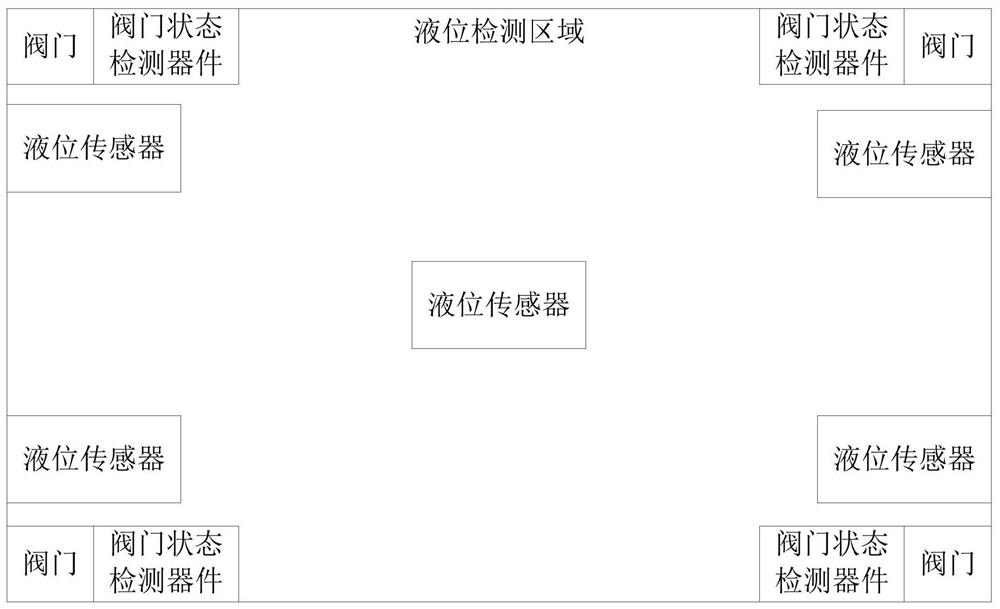

[0027] Each level sensor 120 is provided at different locations of the liquid level detection region, at different locations of the liquid level detection region is provided with a valve for adjusting the mode of operation of the level detection region;

[0028] The level sensor 120, for detecting a position where the level value, and the level value is transmitted to the controller 110;

[0029] The controller 110, according to the working mode of the liquid level detection region, to determine the respective level sensor 120 measuring the weight of the weight; measur...

Embodiment 2

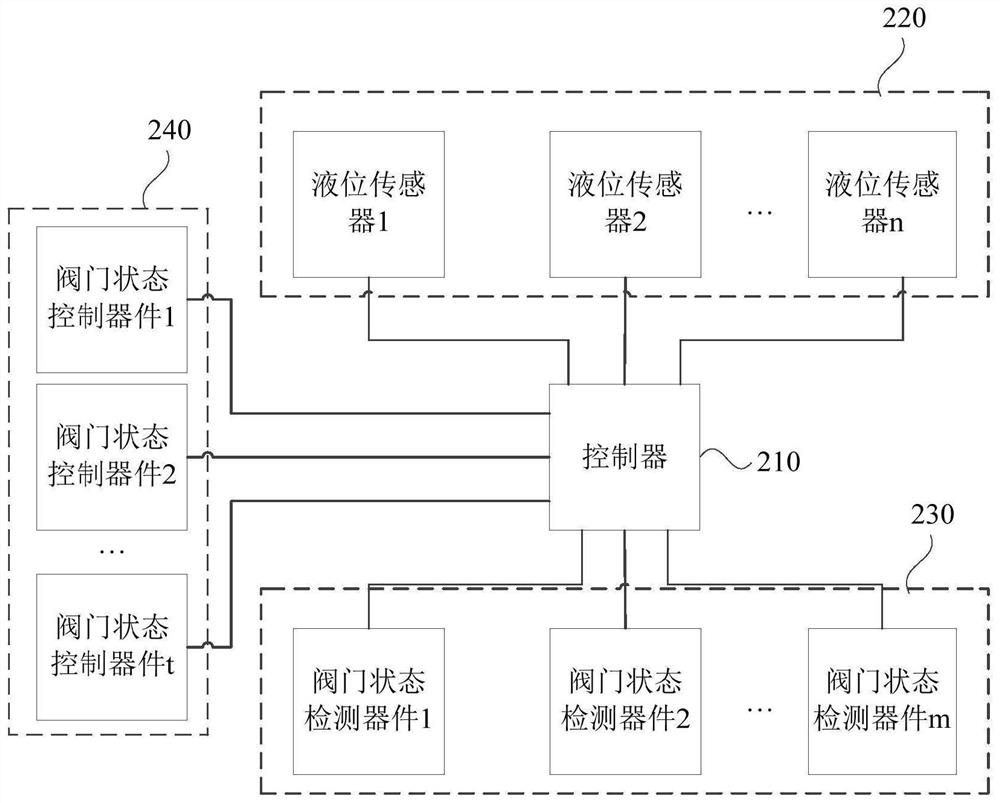

[0042] Figure 2A It is a schematic structure of a liquid level detection system according to a second embodiment of the present invention, embodiments of the present invention, in the above embodiment, the joined state of the valve 230 and valve state detecting device control means 240, the respective embodiments of the present invention the system embodiment includes: a controller 210, a plurality of level sensors 220, a plurality of valve state detection means 230 and a valve control device 240 state. in:

[0043] The controller 210 respectively, each of the level sensor 220, the valves and valve-state detecting means 230 is connected to the state control means 240;

[0044] Each level sensor 220 is provided at different locations within the level detection region, at different locations of the liquid level detection region is provided with a valve for adjusting the mode of operation of the level detection region;

[0045] 220, for detecting a position where the level value of ...

Embodiment 3

[0058] image 3 The apparatus is a flow chart of a method for liquid level detection according to a third embodiment of the present invention, the present embodiment is applicable to the embodiment where the liquid level of the liquid level detection value detected region, the method may be performed by the liquid level detecting means, It may be implemented by software and / or hardware, and integrated in a general computer device, and level sensors, valves and valve-state detecting device state control means used in conjunction.

[0059] like image 3 , The technical solutions of the embodiments of the present invention, includes the following steps:

[0060] S310, obtaining the level sensor measuring the level value of the level at different positions within the detection region, wherein said level at different locations within the detection region is provided with a valve for adjusting the level detection region the mode of operation.

[0061] Wherein the valve comprises an inl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com