Device and method for automatically and indirectly measuring transverse temperature of combustion chamber of coke oven

A combustion chamber and horizontal row technology, applied in the application of measuring devices, thermometers, heating of coke ovens, etc., can solve the problems of high labor intensity of employees, affecting the accuracy of temperature regulation of coke ovens, and inability to respond to temperature changes in a timely manner. The effect of shortening the temperature measurement cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

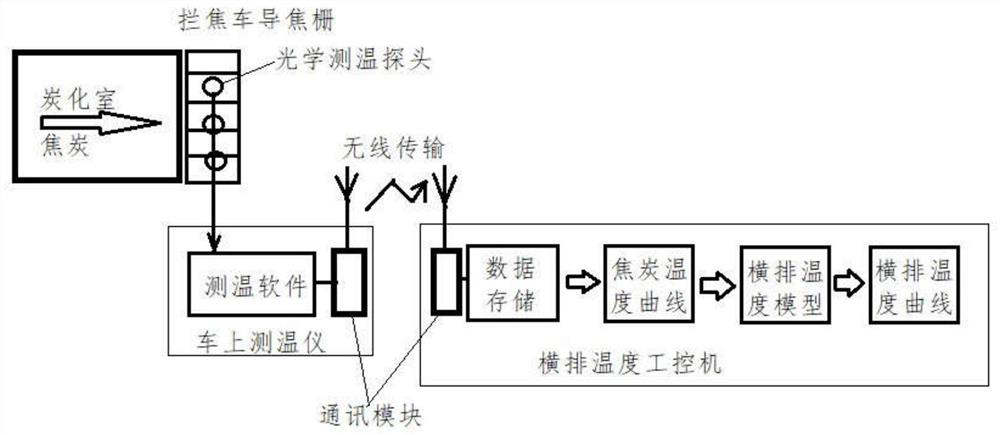

Method used

Image

Examples

Embodiment 1

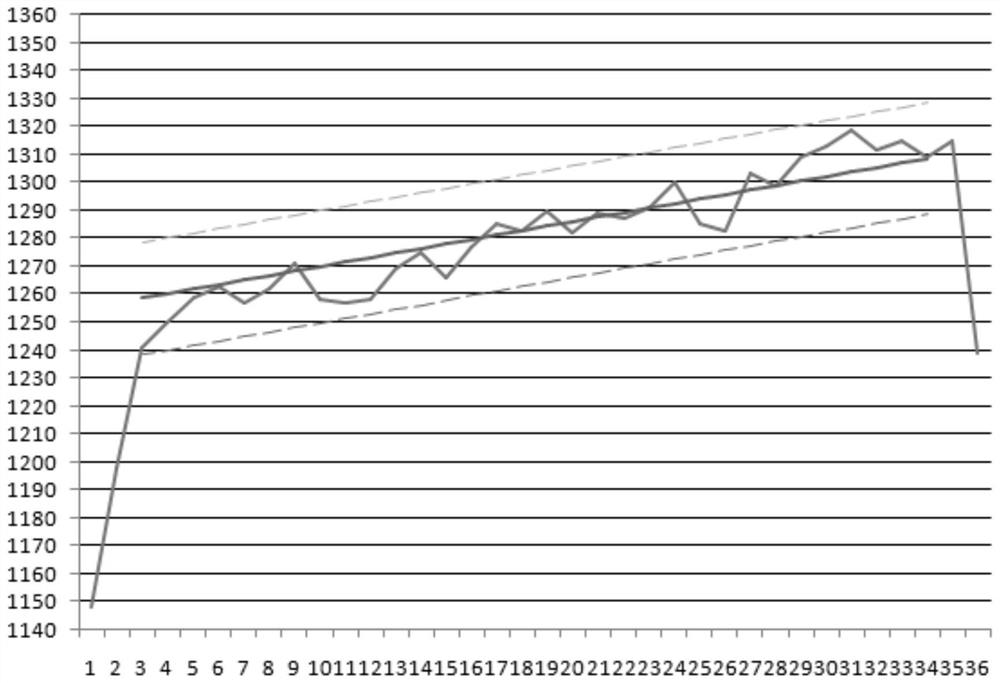

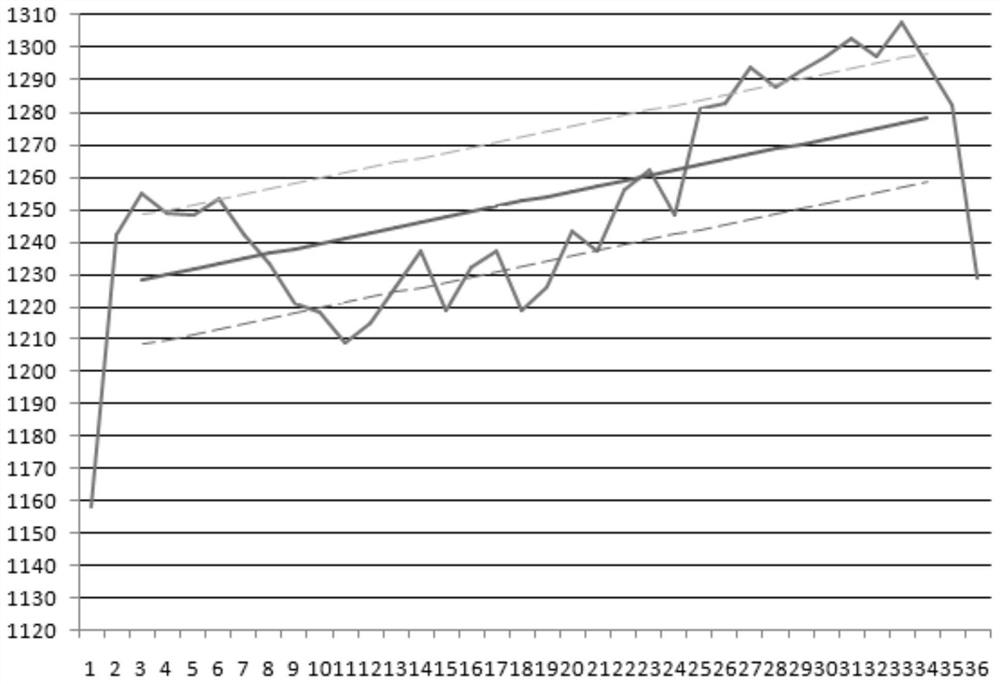

[0049] The method obtained by using the horizontal temperature model of the present invention is as follows: the temperature data of the upper, middle and lower parts of the coke cake measured by the temperature measuring probe are transmitted to the temperature model to form continuous temperature curves of different heights of the upper, middle and lower parts of the coke cake; The temperature point corresponding to the position of the vertical fire channel of the adjacent combustion chamber on the temperature curve is taken out as the temperature data corresponding to the number of vertical fire channels; the manually measured horizontal row temperature data of the adjacent combustion chambers on both sides of the carbonization chamber is input into the temperature model . Linear regression is performed on the temperature data of each burnt cake (upper, middle and lower) and the temperature data of the horizontal row of the vertical fireway at the nearest point on the left a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com