Tobacco cultivation structure and method of tobacco cultivation

A tobacco joint structure technology, applied in the fields of tobacco cultivation, botany equipment and method, plant protection cover, etc., can solve the problems affecting the yield of tobacco leaves and the income of tobacco farmers, affecting the yield of flue-cured tobacco and the income of tobacco farmers, and can not effectively prevent hail, etc., to achieve effective Good for moisturizing, improving lighting effect and improving pitch effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

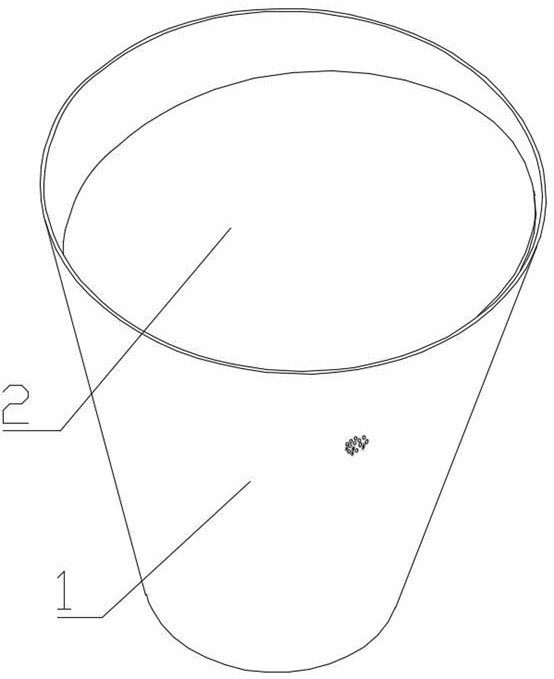

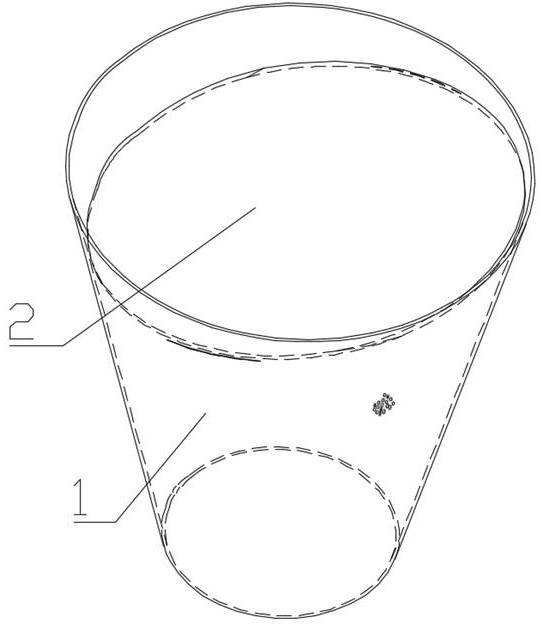

[0054] Such as figure 1 and figure 2 As shown, a tobacco cultivation structure, the first scheme, the structure includes an inverted conical transparent shell 1, an elliptical transparent guide plate 2 is fixed on the upper end side of the transparent shell 1, and the elliptical transparent guide plate 2 is arranged obliquely , The elliptical transparent guide plate 2 and the transparent casing 1 form a groove.

Embodiment 2

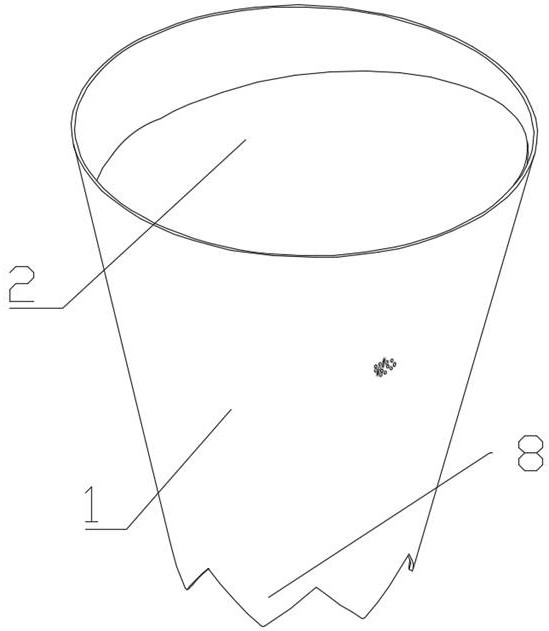

[0056] Such as image 3 and Figure 4 As shown, a structure for tobacco cultivation, the second scheme, the structure includes an inverted conical transparent shell 1, an elliptical transparent guide plate 2 is fixed on the upper side of the transparent shell 1, and the elliptical transparent guide plate 2 is arranged obliquely , The elliptical transparent guide plate 2 and the transparent casing 1 form a groove.

[0057] Scales and ventilation holes 7 are evenly distributed on the outer wall of the transparent housing 1, and sharp teeth 8 are uniformly arranged on the lower end of the transparent housing 1; .

Embodiment 3

[0059] Such as Figure 5 and Figure 6 As shown, a tobacco cultivation structure, the third scheme, the structure includes an inverted conical transparent shell 1, an elliptical transparent guide plate 2 is fixed on the upper end side of the transparent shell 1, and the elliptical transparent guide plate 2 is arranged obliquely , The elliptical transparent guide plate 2 and the transparent casing 1 form a groove.

[0060] The inner wall of the transparent housing 1 is provided with a water guide groove 3; on the oval transparent guide plate 2, a breathable mesh 4 matched with the water guide groove 3 is provided, and the air mesh 4 is located at the lowest end of the ellipse transparent guide plate 2 and is connected with the guide plate The inner walls of the water tank 3 are attached to each other.

[0061] Scales and ventilation holes 7 are evenly distributed on the outer wall of the transparent housing 1, and sharp teeth 8 are uniformly arranged on the lower end of the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com