Automatic capsule medicine packaging and boxing equipment for obstetrics and gynecology department

An automatic packaging, obstetrics and gynecology technology, applied in the directions of packaging, transportation and packaging, packaging item types, etc., can solve the problems of consistent, polluted drugs, difficult drug doses, etc., to improve work efficiency, improve safety, and improve stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

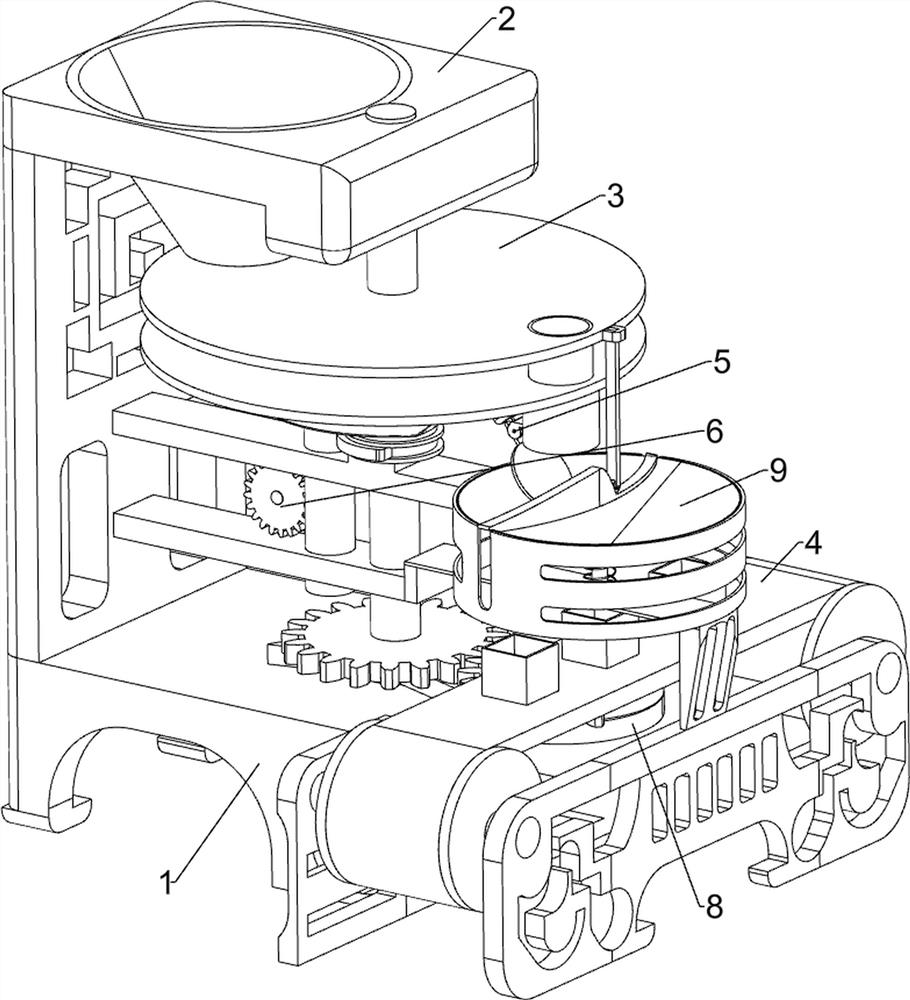

[0065] A device for automatically packing capsules into boxes for obstetrics and gynecology, such as figure 1 and figure 2 As shown, it includes a support frame 1, a mounting plate 2, a rotating mechanism 3, a transmission mechanism 4, a blanking mechanism 5, and an adjusting mechanism 6. A mounting plate 2 is provided on the left side of the top of the support frame 1, and a rotating mechanism is provided in the middle of the support frame 1. 3. A transmission mechanism 4 is provided between the right part of the support frame 1 and the rotating mechanism 3, a blanking mechanism 5 is provided between the middle part of the mounting plate 2 and the upper part of the rotating mechanism 3, and a feeding mechanism 5 is provided between the left middle part of the support frame 1 and the rotating mechanism 3. There is an adjustment mechanism 6.

[0066] When people need to pack capsule medicines into boxes, they first control the amount of each box of medicines after packaging t...

Embodiment 2

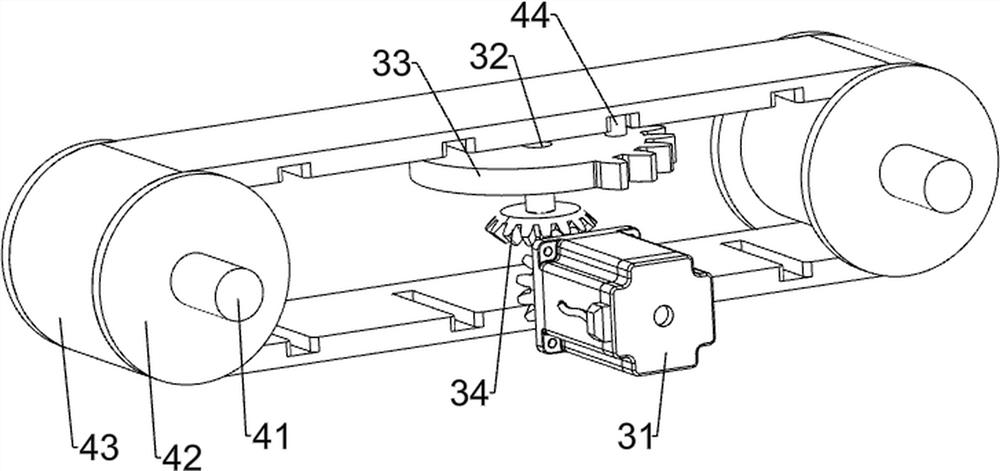

[0068] On the basis of Example 1, such as image 3 , Figure 4 and Figure 6 As shown, the rotating mechanism 3 includes a servo motor 31, a first rotating shaft 32, a missing gear 33, a bevel gear set 34, a second rotating shaft 35, a first spur gear 36, a first disc 37 and a second disc 38, supporting A servo motor 31 is arranged on the front side of the middle part of the frame 1, and a first rotating shaft 32 is arranged on the front side of the right part of the support frame 1. A bevel gear set 34 is arranged between the bottom of the first rotating shaft 32 and the output shaft of the servo motor 31. The first rotating shaft 32 tops are provided with lacking gear 33, and support frame 1 top center rotation type is provided with second rotating shaft 35, and second rotating shaft 35 bottoms are provided with first straight gear 36, and first spur gear 36 and missing gear 33 mesh with each other, and second rotating shaft 35 upper sliding type is provided with the first...

Embodiment 3

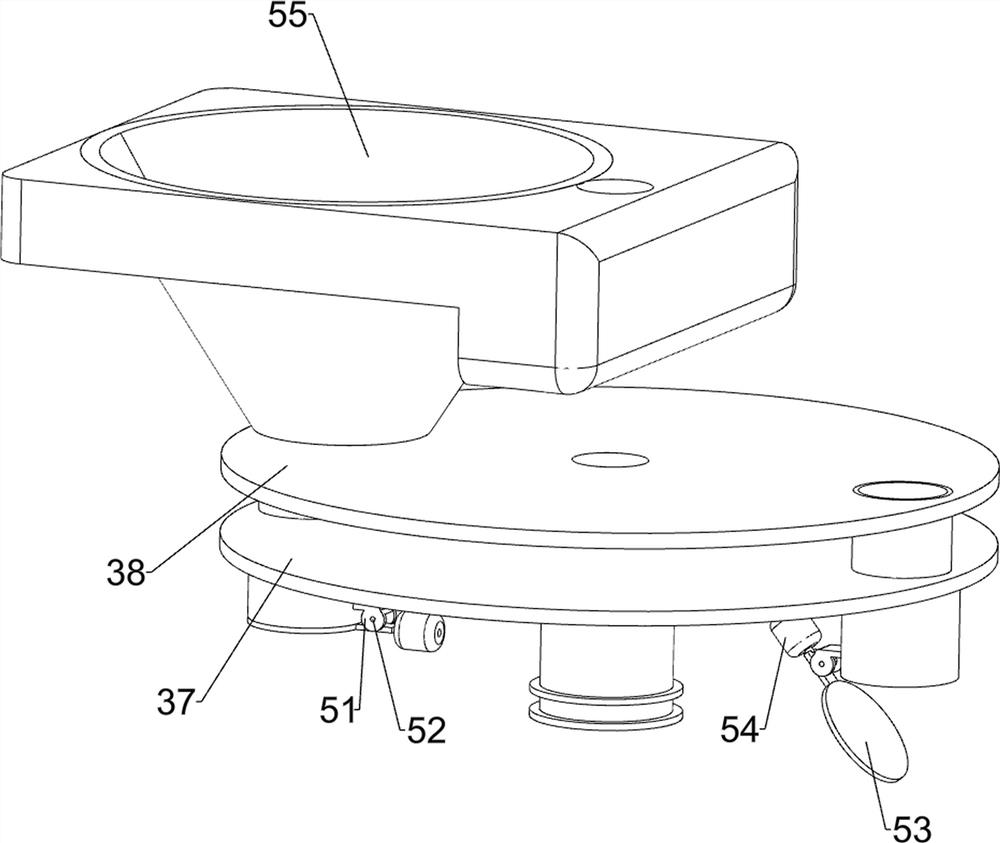

[0075] On the basis of Example 2, such as Figure 5 , Figure 6 and Figure 7 As shown, the blanking mechanism 5 includes a second fixed block 51, a fourth rotating shaft 52, a material blocking plate 53, a second roller 54 and a material storage box 55, and the middle part of the mounting plate 2 is provided with a material storage box 55, and the material storage The bottom of the box body 55 is in contact with the top of the second disk 38, and the lower part of the opposite side of the large cylinder is provided with a second fixed block 51, and the middle part of the opposite side of the second fixed block 51 is provided with a fourth rotating shaft 52. On the fourth rotating shaft 52 The baffle plate 53 is provided in the uniform rotation type, and the top of the baffle plate 53 is in contact with the bottom of the large cylinder on one side away from each other. The rails 64 cooperate with each other.

[0076] When people need to pack capsule medicines into boxes, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com