Stirrer for glass fiber reinforced plastic septic tank

A glass tempering and mixer technology, which is applied to mixer accessories, mixers with rotating agitation devices, mixers, etc., can solve the problems of inability to realize automatic switching, inability to automatically adjust the output power of stirring motors, etc., to achieve suitable promotion and use, and improve Stirring efficiency and the effect of improving operating power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

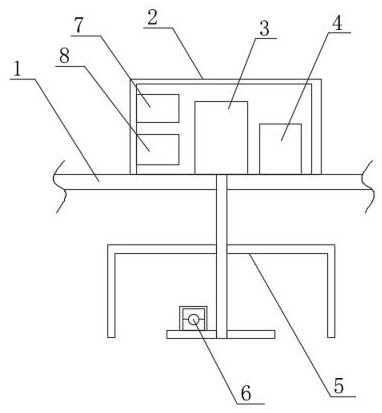

[0018] see figure 1 , this embodiment provides a technical solution:

[0019] A mixer for FRP septic tanks, comprising an equipment box 2 and a septic tank 1, the equipment box 2 is fixedly arranged on the top plate of the septic tank 1, and the inner bottom plate of the equipment box 2 is fixedly arranged with agitators sequentially from left to right The motor 3 and the relay 4, the bottom of the stirring motor 3 is provided with a rotating shaft extending into the septic tank 1, the rotating shaft is fixedly provided with an agitator 5, the bottom of the agitator 5 is provided with a viscosity sensor 6, and the left side of the equipment box 2 is A PLC controller 7 and a frequency converter 8 are fixedly arranged on the inner wall sequentially from top to bottom.

[0020] Wherein, the stirring motor 3 is connected to the frequency converter 8 through a circuit, the relay 4 is connected to the relay 4 through a circuit, and the relay 4 is connected to an external power supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com