Glass sleeve wire-drawing forming machine

A glass sleeve and forming machine technology, applied to glass manufacturing equipment, manufacturing tools, etc., can solve the problems of increased labor costs, high scrap rate, low efficiency, etc., and achieve the effects of easy operation, waste reduction, and reduced scrap rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The present invention will be described in further detail below in conjunction with specific examples, but the embodiments of the present invention are not limited thereto.

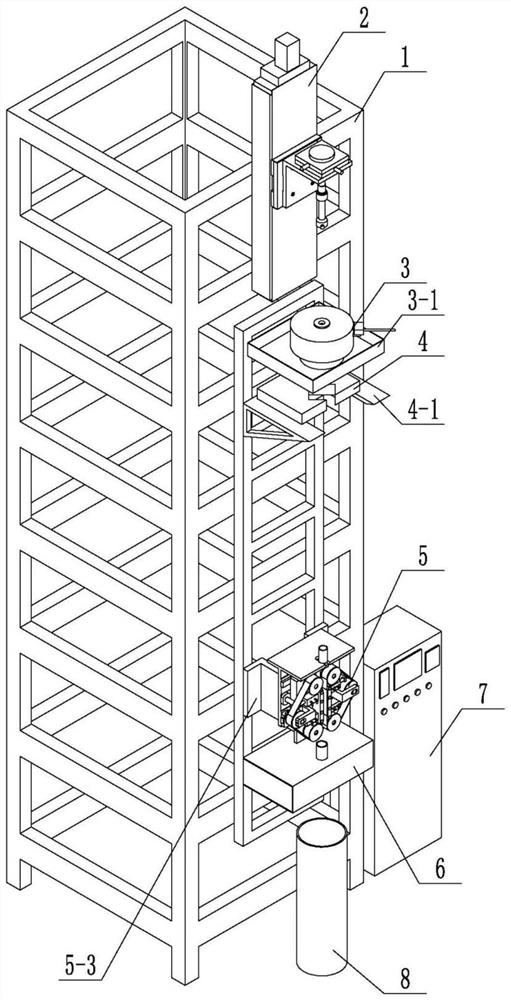

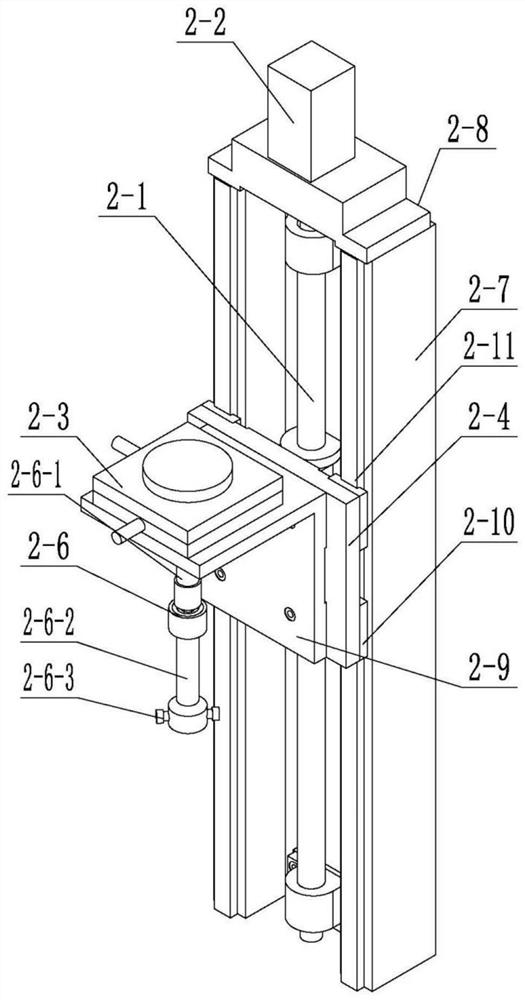

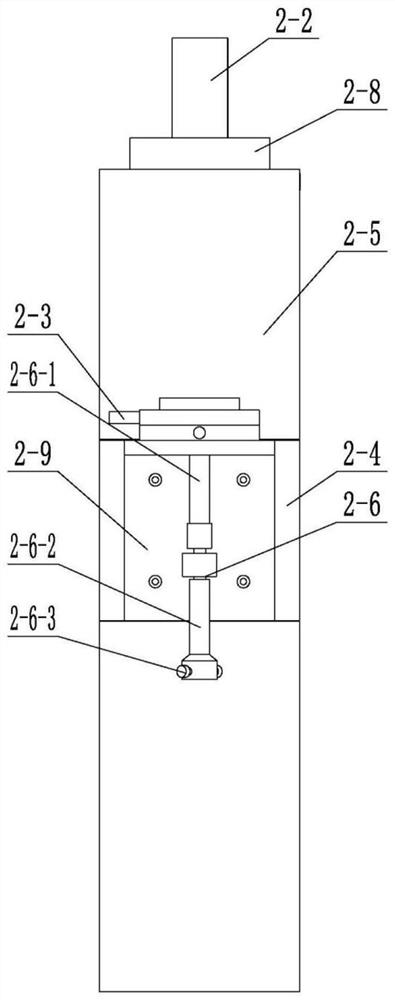

[0054] See figure 1 and figure 2 , the embodiment of the present invention provides a glass casing wire drawing forming machine, which specifically includes: a frame 1, a feeding device 2, a heating device 3, a diameter measuring device 4, a wire drawing device 5, an automatic cutting device 6 and a control box 7; ,

[0055] The feeding device 2, the heating device 3, the wire drawing device 5 and the automatic cutting device 6 are sequentially installed on the frame 1 from top to bottom, and the centers of the feeding device 2, the heating device 3, the wire drawing device 5 and the automatic cutting device 6 are located in the same vertical On a straight line; the diameter measuring device 4 is fixed on the frame 1 through the bracket 4-1, and is horizontally located below the heating device 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com