Organic-inorganic composite coated metal wave-absorbing filler and preparation method thereof

A composite coating type, wave absorbing filler technology, applied in chemical instruments and methods, other chemical processes, electrical components, etc. Corrosion performance, surface energy reduction, hydrophobicity improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

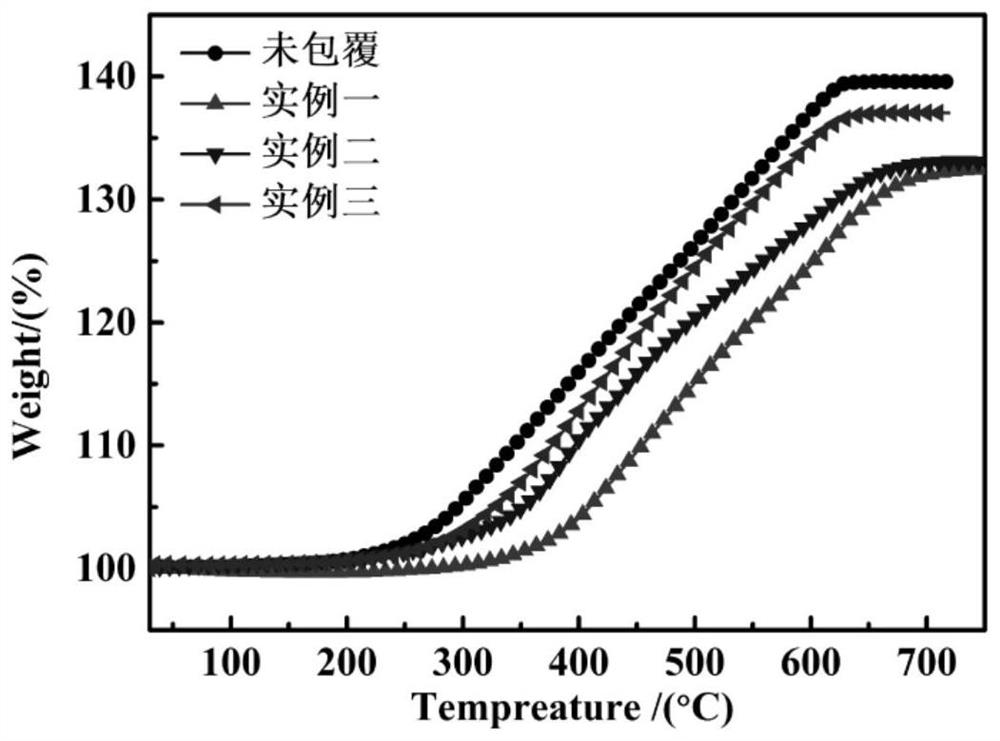

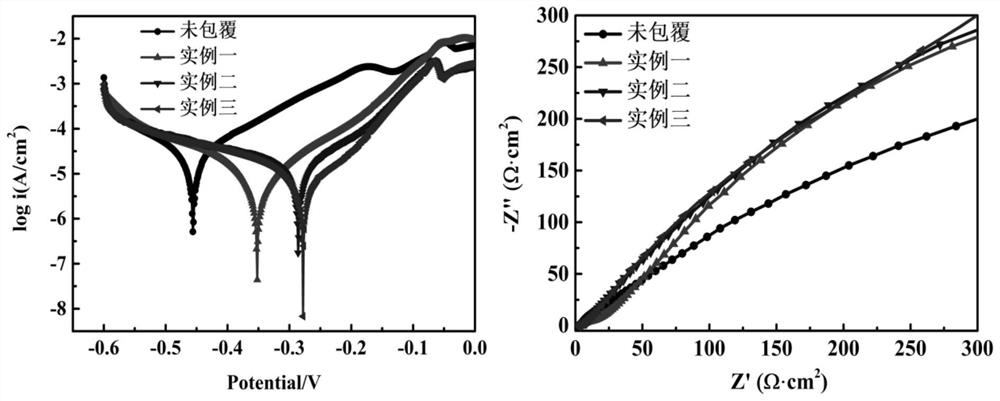

Embodiment 1

[0029] Step 1: Take 40 parts by mass of flaky carbonyl iron powder, the length and width are 4-7um, 2-3um, and the thickness is 0.3-0.5um, and ultrasonically mix with 200 parts of 0.04mol / L hydrochloric acid solution prepared for 10min , after standing at room temperature for 1 hour, filter, wash with deionized water and ethanol in turn until the system is clear, then filter with suction, and dry in vacuum at 50°C for 24 hours, and the prepared powder is ready for use;

[0030] Step 2: Mix 8 parts by mass of the powder obtained in step 1 with 71 parts by mass of absolute ethanol in a four-necked flask to obtain dispersion system A;

[0031] Step 3: 2.85 parts by mass of tetraethoxysilane (TEOS), 1.34 parts by mass of perfluorooctyltriethoxysilane (PC9757), and 34.5 parts by mass of absolute ethanol were ultrasonically mixed for 10 minutes to obtain a mixed solution B;

[0032] Step 4: Take 5.49 parts by mass of ammonia water, 4.26 parts by mass of deionized water, and 34.5 par...

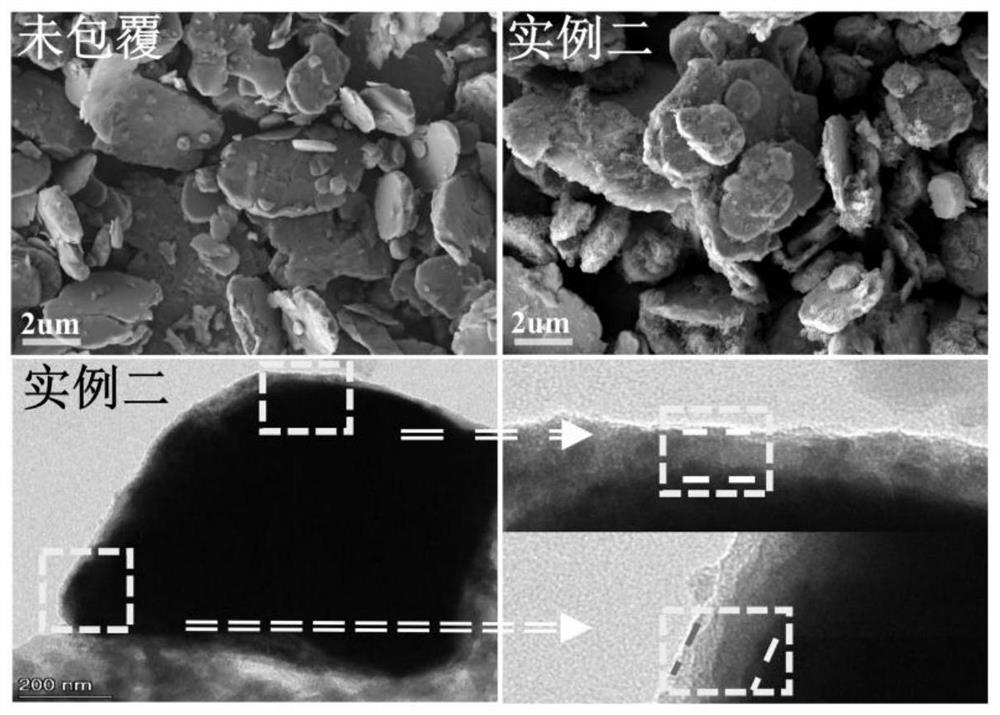

Embodiment 2

[0036]Step 1: Take 60 parts by mass of flaky carbonyl iron powder, the length and width are 4-7um, 2-3um, and the thickness is 0.3-0.5um, and ultrasonically mix with 300 parts of 0.05mol / L hydrochloric acid solution prepared for 10min , after standing at room temperature for 1.5h, filter, wash with deionized water and absolute ethanol in sequence until the system is clear, then filter with suction, and finally vacuum-dry at 50°C for 30h, and the prepared powder is ready for use;

[0037] Step 2: Mix 8 parts by mass of the powder prepared in step 1 with 94.7 parts by mass of absolute ethanol in a four-necked flask to obtain dispersion system A;

[0038] Step 3: 1.9 parts by mass of tetraethoxysilane (TEOS), 2.68 parts by mass of perfluorooctyltriethoxysilane (PC9757), and 46 parts by mass of absolute ethanol were ultrasonically mixed for 10 minutes to obtain a mixed solution B;

[0039] Step 4: Take 7.32 parts by mass of ammonia water, 7.5 parts by mass of deionized water, and ...

Embodiment 3

[0044] Step 1: Take 80 parts by mass of flaky carbonyl iron powder, the length and width of which are 4-7um and 2-3um respectively, and the thickness is 0.3-0.5um, and ultrasonically mix with 400 parts of 0.06mol / L hydrochloric acid solution prepared for 10min , stand at room temperature for 2 hours, filter, wash with deionized water and ethanol in sequence, then filter with suction, and dry in vacuum at 50°C for 48 hours, and the obtained powder is ready for use;

[0045] Step 2: Mix 8 parts by mass of the powder obtained in step 1 with 118.4 parts by mass of absolute ethanol in a four-necked flask to obtain dispersion system A;

[0046] Step 3: 0.95 parts by mass of tetraethoxysilane (TEOS), 4.02 parts by mass of perfluorooctyltriethoxysilane (PC9757) and 57.5 parts by mass of absolute ethanol were ultrasonically mixed for 10 minutes to obtain a mixed solution B;

[0047] Step 4: 9.15 parts by mass of ammonia water, 10.74 parts by mass of deionized water, and 57.5 parts by m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com