Preparation method of astaxanthin wine

A production method and technology of astaxanthin, applied in the preparation of alcoholic beverages, etc., can solve the problems of difficult dissolution of astaxanthin, achieve the effects of inhibiting seafood allergy, stable properties, and solving solubility and stability problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

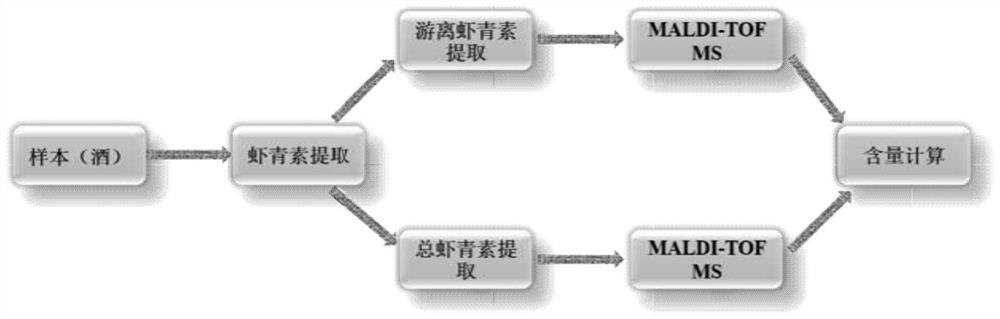

Method used

Image

Examples

Embodiment 1

[0034] Take 10 kg of frozen sea shrimp shells, use a meat grinder to grind the shrimp shells into long, 0.1-0.5 cm wide shrimp shells, put them in the digestive canal, add alkaline protease at a ratio of 1000:1, and heat up to 45° , at a stirring rate of 30 revolutions per minute, digest at a constant temperature for 3 hours, separate the solid from the liquid, and obtain the filtrate. Then the filtrate is centrifuged again, the liquid is removed and the solid is retained, and the shrimp protein rich in astaxanthin is obtained. Then add the obtained shrimp protein into distilled water or purified water at a mass ratio of 1:2, and add perilla oil and ginger juice at a volume ratio of 100:2:2. After stirring for 30 minutes, the solid-liquid separation was carried out to remove the fishy smell, and the liquid was removed to leave the solid, leaving the shrimp protein solid, which weighed 982 grams. Add 5892 grams of 60-degree edible liquor to the shrimp protein solid at a ratio ...

Embodiment 2

[0104] Take 10 kilograms of frozen crayfish shells, and grind the shrimp shells into 0.1-0.5 cm shrimp shells with a meat grinder. Add alkaline protease to the digestive canal at a mass ratio of 1000:1, raise the temperature to 45°, digest at a constant temperature for 3 hours at a stirring rate of 30 rpm, separate the solid and liquid from the canal and filter, and then centrifuge the filtrate Separating, removing the liquid and retaining the solid to obtain shrimp protein rich in astaxanthin. Then add the obtained shrimp protein into distilled water or purified water at a mass ratio of 1:2, and add perilla oil and ginger juice at a volume ratio of 100:2:2. After stirring for 30 minutes, carry out solid-liquid separation to remove fishy smell, remove the liquid and leave the solid, leaving the shrimp protein solid, which weighs 1100 grams. Add 6600 grams of 60-degree grain wine to the shrimp protein solid at a ratio of 1:6, put it into the pot, stir at a rate of 30 rpm for 6...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com