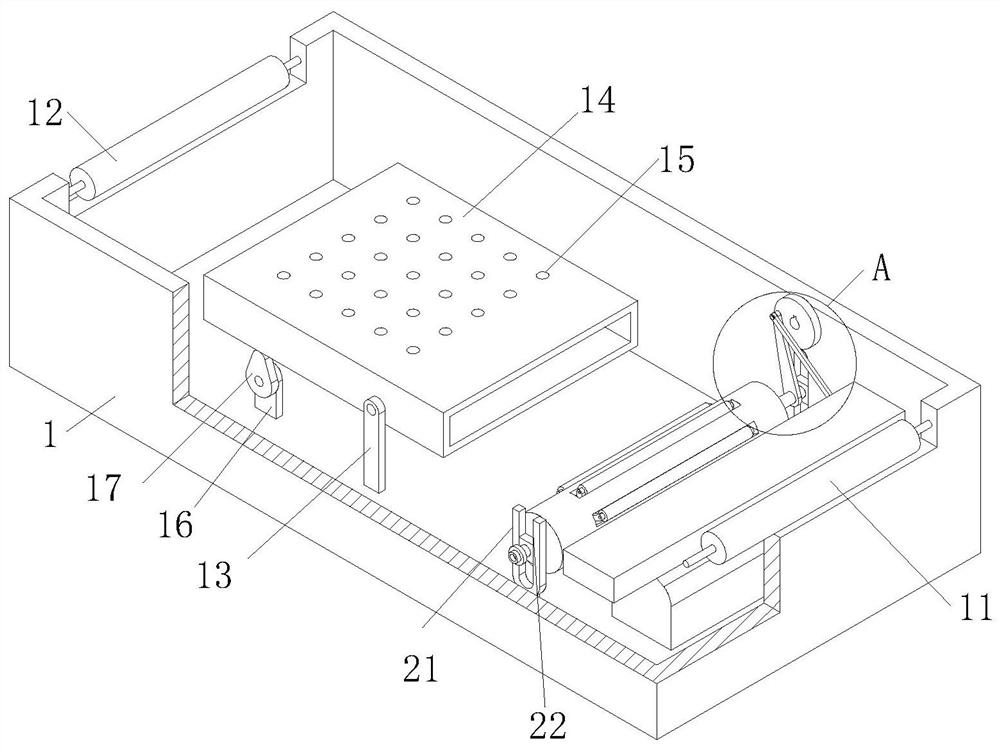

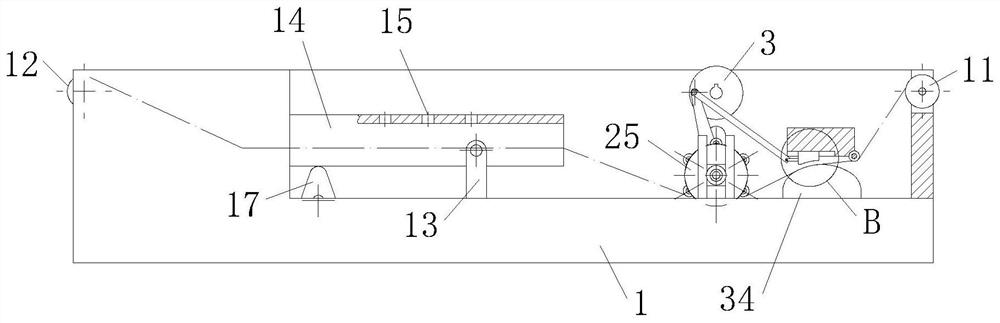

Open-width washing machine for textile fabrics

A technology of open-width washing and textile fabrics, which is applied in the processing of textile materials, textile processing machine accessories, processing textile material drums, etc., can solve the problems of inability to clean the fabric, pollution, consumption of large amounts of water, etc., to increase the frequency of stretching and shrinking , Increase the cleaning effect, increase the effect of washing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

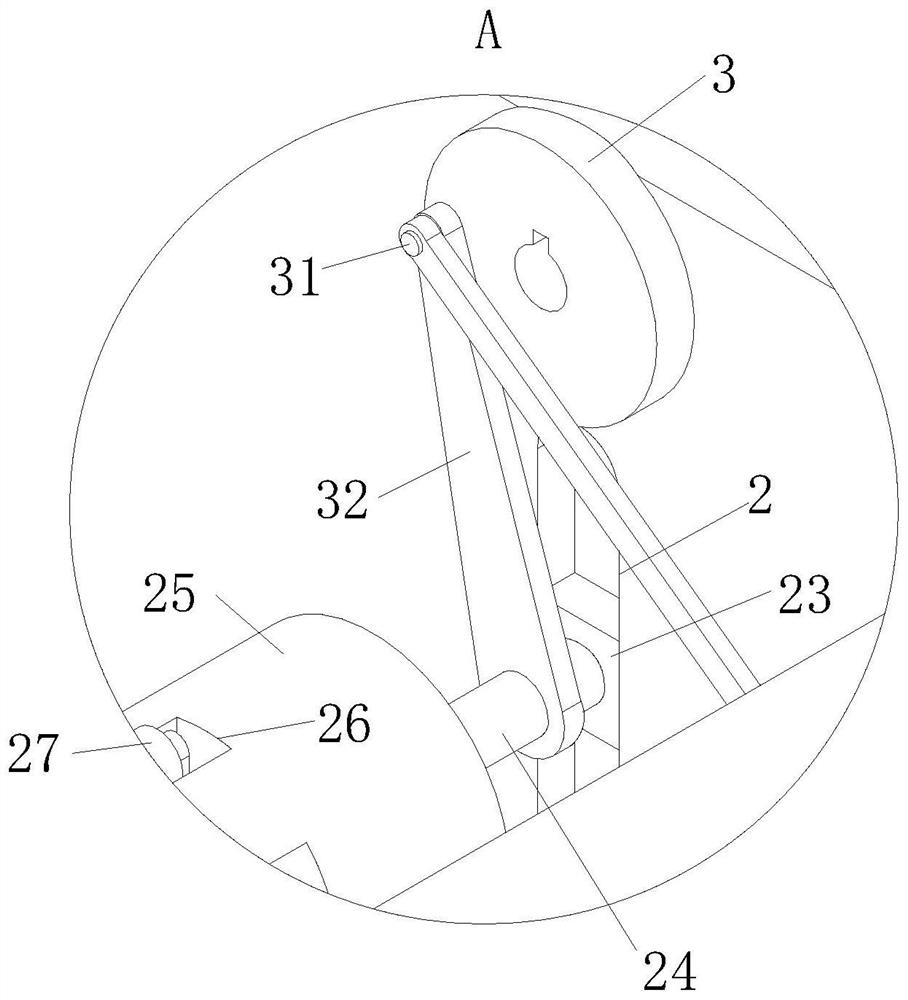

[0026] As an embodiment of the present invention, an upper baffle 33 and a lower baffle 34 are fixedly connected to the position between the driving roller 25 and the unwinding roller 11 in the water tank 1, and the top of the lower baffle 34 is provided with an arc-shaped inverted Angle; the No. 3 chute 35 provided at the bottom of the upper baffle 33 is slidably connected with an extruding block 36, and the bottom of the extruding block 36 cooperates with the lower baffle 34; the extruding block 36 is close to one end of the driving roller 25 The second connecting rod 38 is hinged through the support 37, and the other end of the second connecting rod 38 is connected to the rotating pin 31 in rotation; when the eccentric wheel 3 drives the rotating pin 31 to rotate, the rotating pin 31 is vertically moved to the bottom of the water tank 1 When moving, the revolving pin 31 pushes down the No. 2 connecting rod 38, and then the No. 2 connecting rod 38 pushes the bearing 37 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com