Processing method of blended polar fleece fabric with CDP looped piles as bottom yarns

A processing method and polar fleece technology, applied in the textile field, can solve problems such as difficult-to-control cloth surface style production reproducibility, bottom surface color inconsistency, etc., to achieve the effect of ensuring stability and improving sour taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

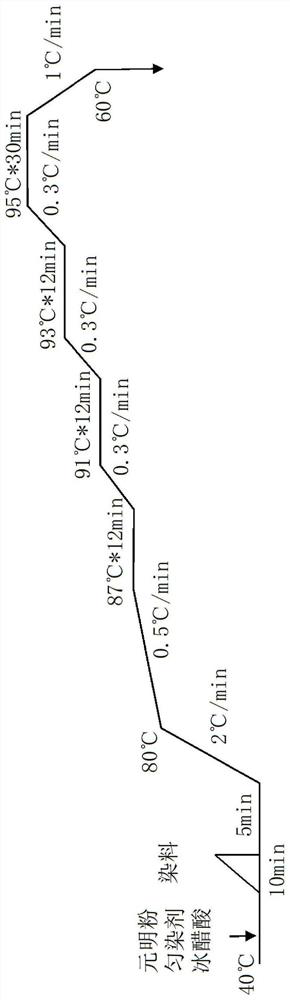

[0056] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

[0057] The equipment and equipment parameters are: high temperature and high pressure overflow dyeing machine produced by Suzhou Bazzoni Machinery Equipment Co., Ltd., the main pump pressure is 800, the nozzle is 50%, and the lap time is 90S / turn.

[0058] During the entire dyeing process, except for cationic dyes that require high-temperature chemicals, the rest of the dyes and auxiliaries are automatically conveyed by the conveying system provided by Taiwan Liuya Technology Co., Ltd.

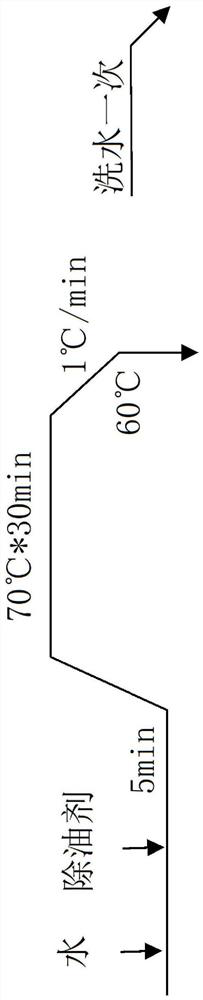

[0059] Pretreatment of blended polar fleece fabrics:

[0060]According to the bath ratio of 1:10, add water and degreasing agent into the dyeing machine and run for 5 minutes, wherein the content of degreasing agent is 2g / L; heat up to 70°...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com