Environment-friendly resin wall film and production process thereof

An environmentally friendly resin and production process technology, applied to other household appliances, applications, household appliances, etc., can solve the problems of not being able to adapt to large wall integrated film, production, transportation, storage, construction inconvenience, etc., to ensure color stability , enhance color stability, reduce corrosive effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

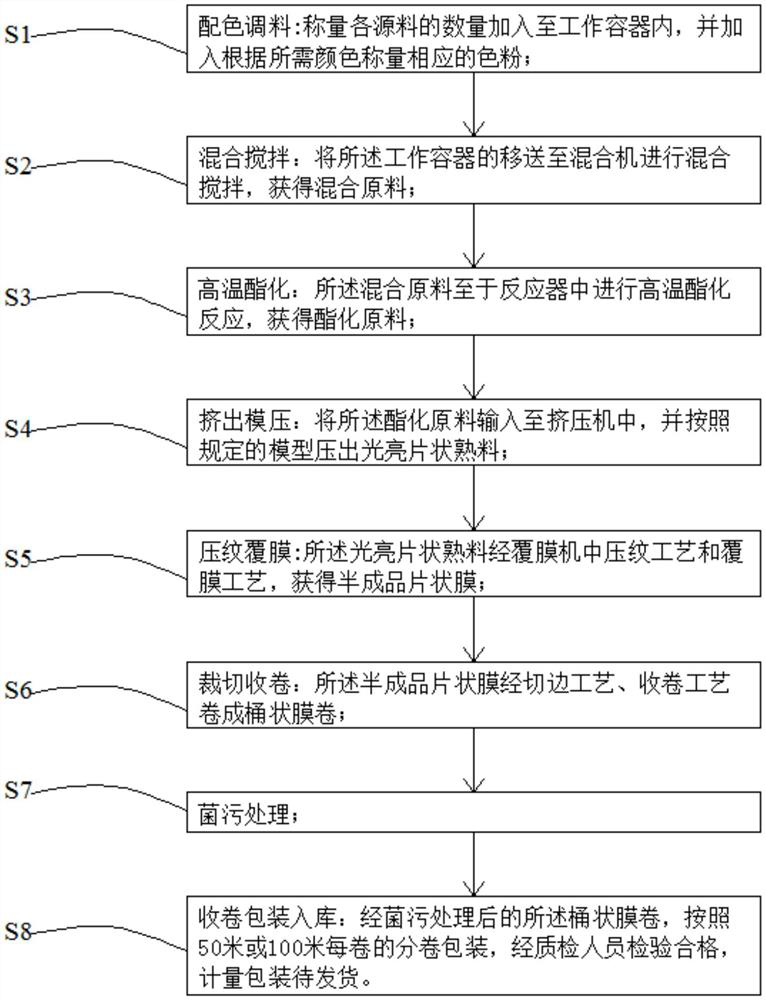

[0043] This embodiment includes the following steps:

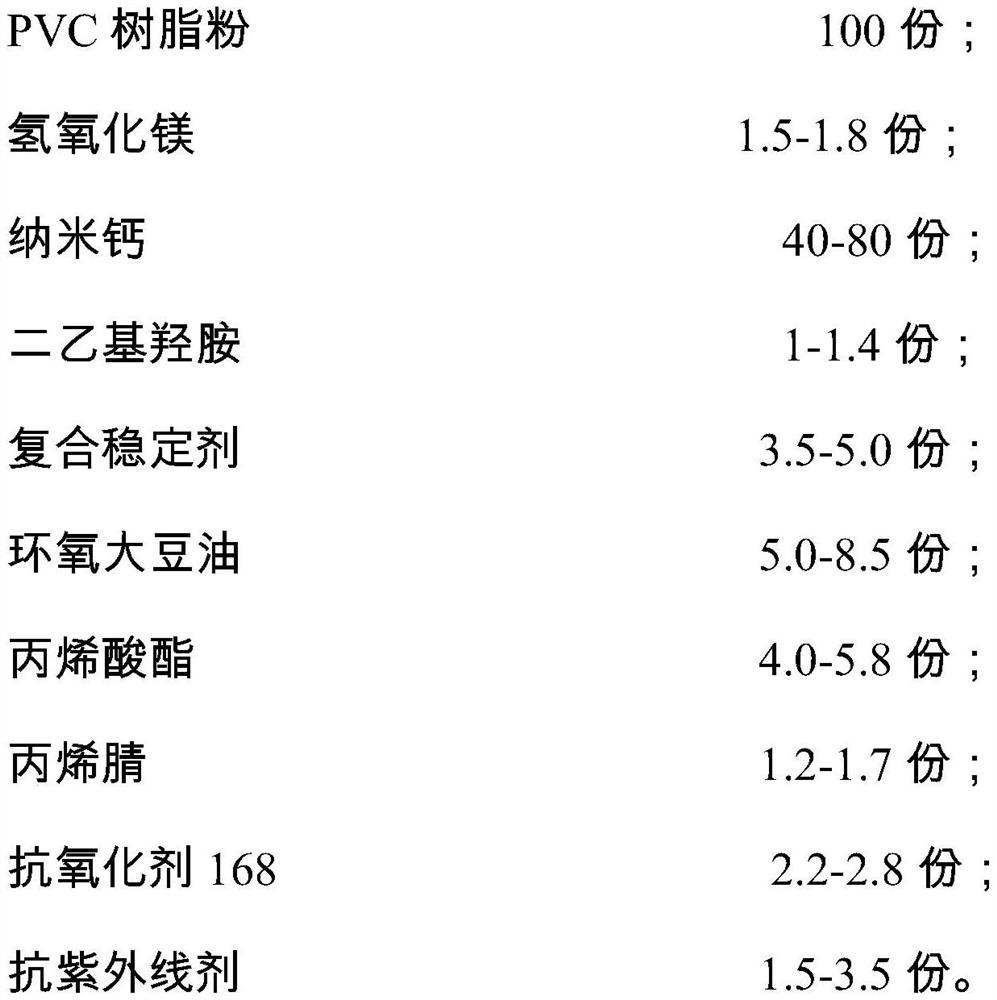

[0044] S1. Color matching: Weigh the weight of each raw material in the table below and add it to the mixing tank;

[0045] raw material Specification mass (kg) PVC resin powder The degree of polymerization is 800 300 magnesium hydroxide Mass fraction 95%, particle size 400 mesh 4.5 Nano calcium Nano calcium carbonate 120 Diethylhydroxylamine / 3 Composite stabilizer Calcium zinc stabilizer 10.5 Epoxidized soybean oil / 15 Acrylate / 12 Acrylonitrile / 3.6 Antioxidant 168 / 6.6 Anti-ultraviolet agent UV-531 4.5 Toner yellow, red, black 18.9

[0046]S2, mixing and stirring: transfer the mixing tank to the mixer for mixing and stirring to obtain mixed raw materials, wherein the rotation speed of the mixing mixer is 1400r / min, and the power of the mixing mixer is 30kw;

[0047] S3. High-temperature esterification: the mixed ra...

Embodiment 2

[0054] In this embodiment, S1, color matching: weigh the weight of each raw material in the following table and add it to the stirring tank;

[0055] raw material Specification mass (kg) PVC resin powder The degree of polymerization is 800 300 magnesium hydroxide Mass fraction 95%, particle size 400 mesh 5.4 Nano calcium Nano calcium carbonate 240 Diethylhydroxylamine / 4.2 Composite stabilizer Calcium zinc stabilizer 15 Epoxidized soybean oil / 25.5 Acrylate / 17.4 Acrylonitrile / 5.1 Antioxidant 168 / 8.4 Anti-ultraviolet agent UV-328 10.5 Toner yellow, red, black 22.5

[0056] The difference between this embodiment and embodiment 1 is that: in the S2 step, the rotation speed of the mixing mixer is 1600r / min; in the S3 step, the temperature in the reaction tank is 170°C; In the step, the temperature of the laminating machine is 160°C.

Embodiment 3

[0058] In this embodiment, S1, color matching: weigh the weight of each raw material in the following table and add it to the stirring tank;

[0059] raw material Specification mass (kg) PVC resin powder The degree of polymerization is 800 300 magnesium hydroxide Mass fraction 95%, particle size 400 mesh 4.8 Nano calcium Nano calcium carbonate 140 Diethylhydroxylamine / 3.9 Composite stabilizer Calcium zinc stabilizer 14 Epoxidized soybean oil / 18 Acrylate / 16 Acrylonitrile / 4 Antioxidant 168 / 7.7 Anti-ultraviolet agent UV-328 7 Toner yellow, red, black 21.3

[0060] The difference between this embodiment and Embodiment 1 lies in that the thickness of the semi-finished sheet film is 0.8 mm, and it is packaged in rolls of 50 meters per roll.

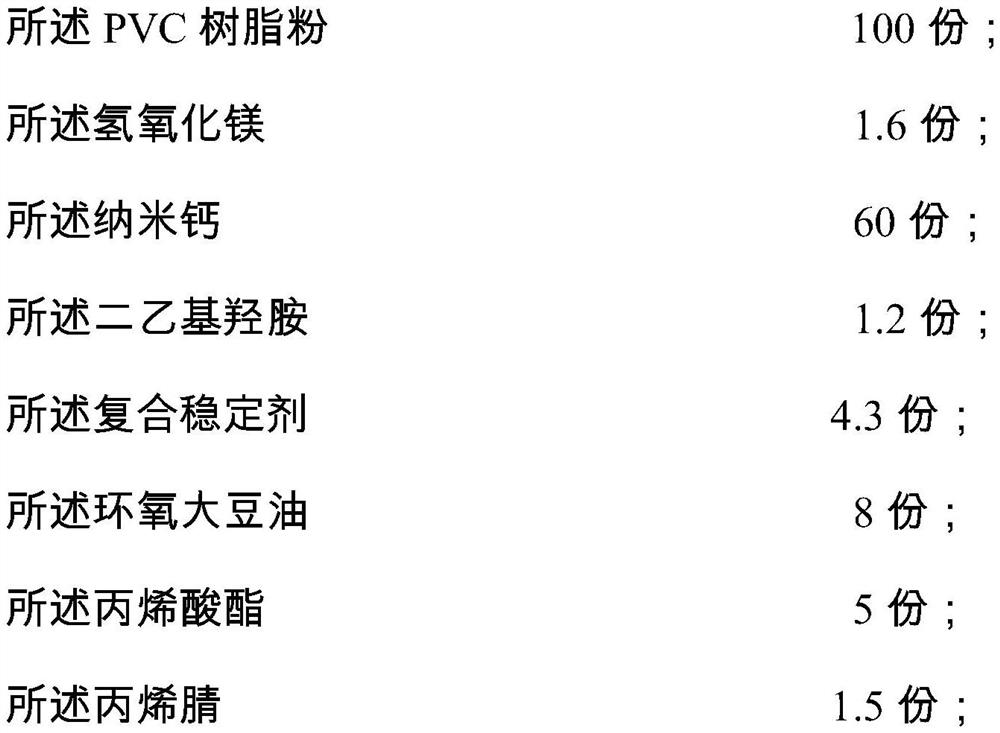

[0061] Best Practices

[0062] This embodiment includes the following steps:

[0063] S1. Color matching: Weigh the weight of each r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com