Upstream type high-strength reinforced wide-top damming method and structure for fine-particle tailings

An upstream, high-strength technology, applied in infrastructure engineering, construction, water conservancy engineering, etc., can solve the problem that the calculation of dam safety and dynamic stability is difficult to meet the requirements of the code, the difficulty of direct dam construction with tailings, and the deposition of tailings ponds In order to improve the physical and mechanical properties, accelerate the drainage consolidation and improve the stability and safety factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

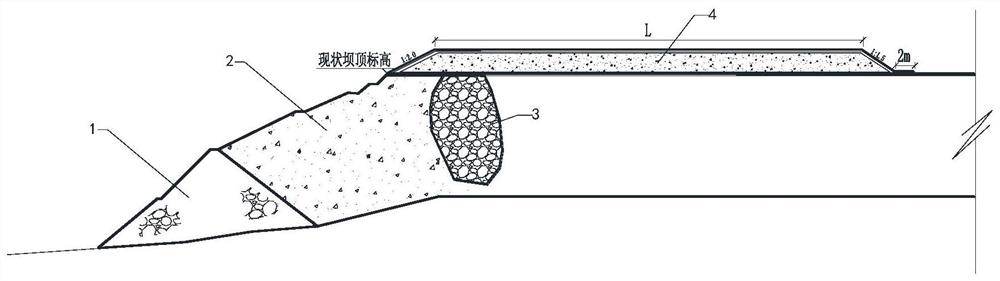

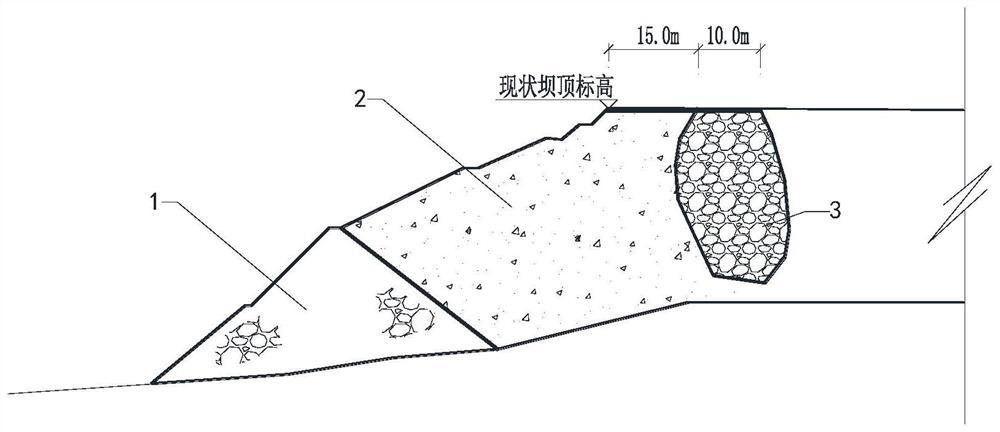

[0027] Such as figure 1 Shown, a kind of fine-grained tailings upstream type high-strength reinforced wide-top dam construction method of the present invention comprises the following steps:

[0028] S1. Carry out riprap silting at a certain distance from the upstream side of the beach surface of the existing accumulation dam 2 to reinforce the beach surface to form a riprap silting area 3;

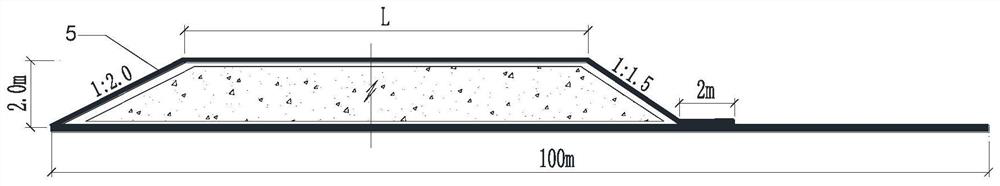

[0029] S2, laying high-strength reinforced and corrosion-resistant geotextile 5 on the reinforced beach surface formed after riprap silting is completed;

[0030] S3. On the top of the high-strength reinforced and corrosion-resistant geotextile 5, the sub-dam 4 is piled up by using ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com