Deepwater pile foundation steel casing construction method suitable for bare rock geological conditions

A technology of geological conditions and construction methods, applied in the direction of foundation structure engineering, drilling equipment and methods, sheet pile walls, etc., can solve the problems of difficult construction of pile foundation steel casings, easy slurry leakage at the bottom of casings, slow progress, etc. , to achieve the effect of ensuring the quality of pile foundation construction, short construction period, and less investment in equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

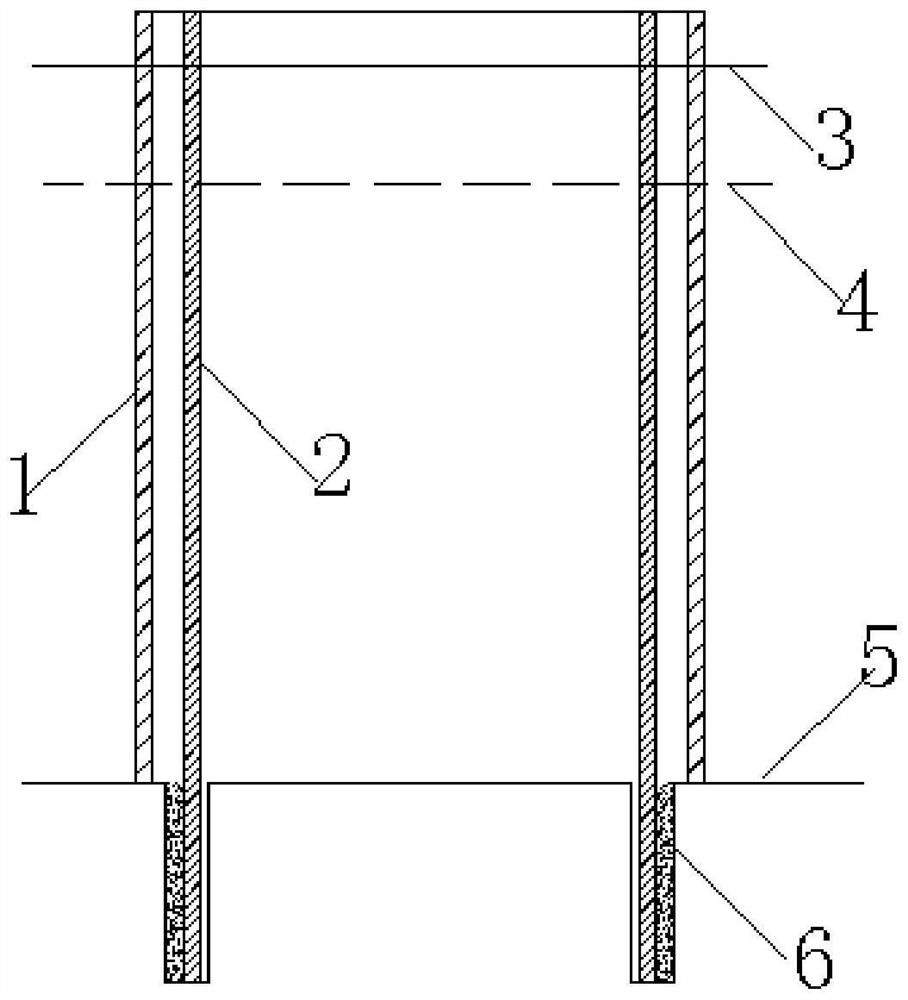

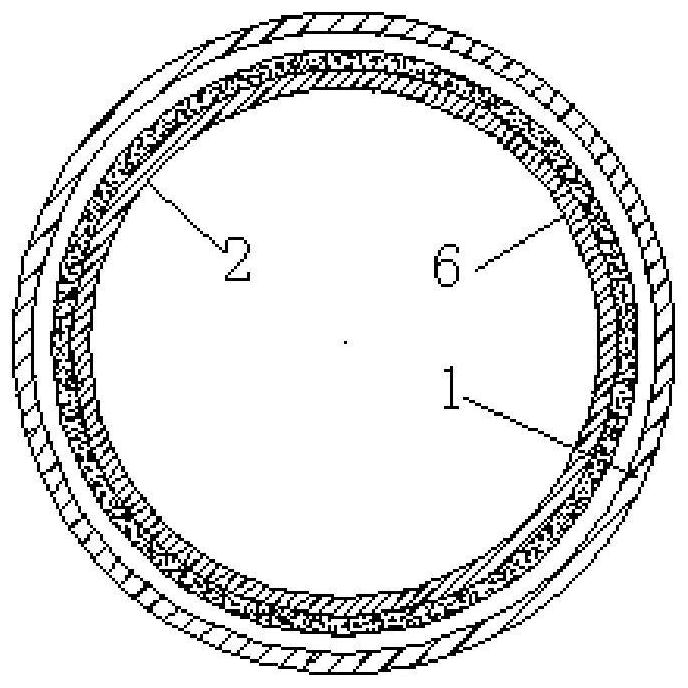

[0021] given in the present invention figure 1 , figure 2 , image 3 In the embodiment, the outer jacket casing 1 is a circular steel casing, and the wall thickness can be determined according to the construction conditions. Generally, it can be selected as a steel plate with a thickness of 16-25mm. Its function is to block the impact of water flow on the cone bit The drill bit plays the role of guiding and positioning.

[0022] The construction casing 2 is a steel circular casing, which is used as the casing structure for the construction of the main body of the pile foundation.

[0023] The size of the cone drill bit should match the construction casing, and the rotary drilling rig provides power for the cone drill bit to pressurize and rotate the drill bit, cutting the rock surface to form an annular groove, so that the construction casing can just fall into the annular groove bit inside.

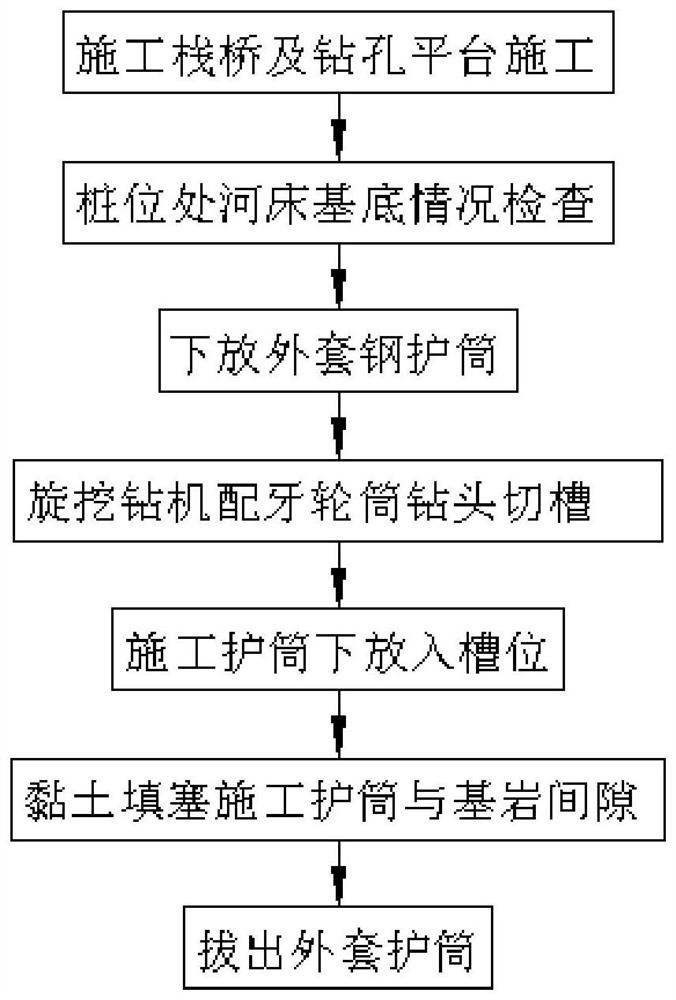

[0024] The method of the present invention to bare rock deep-water pile foundat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com