Building drainage collection system

A technology for building drainage and drainage pipes, used in waterway systems, buildings, drainage structures, etc., can solve the problems of small maintenance space, inability to maintain, and high production costs, reducing the space occupied, preventing odor from overflowing, increasing The effect of the radius of curvature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

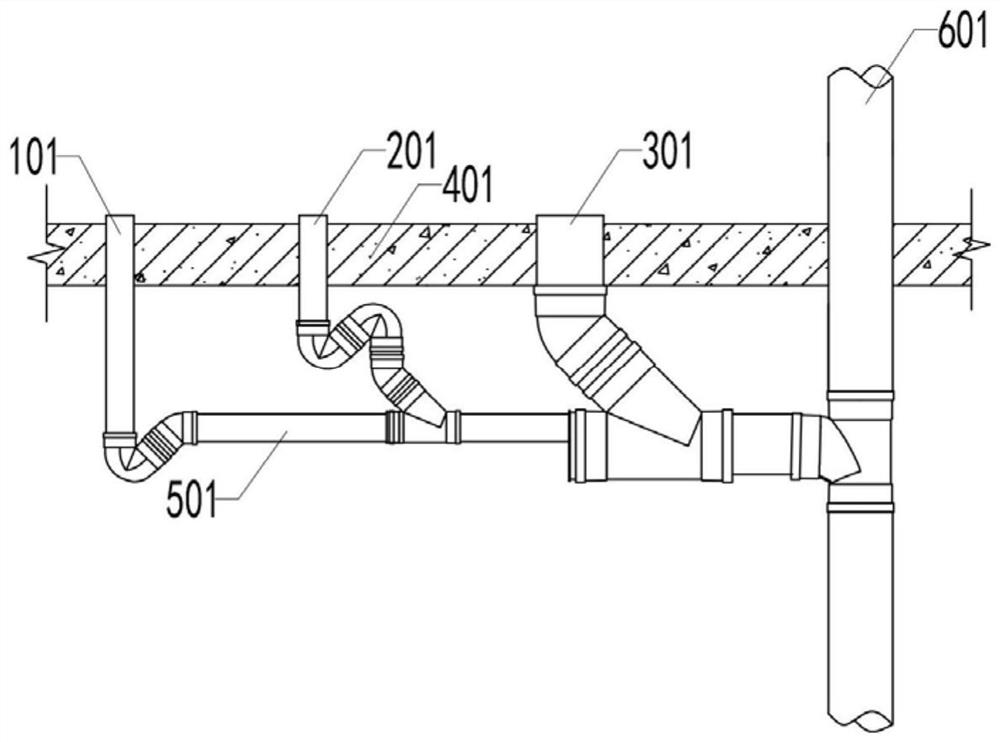

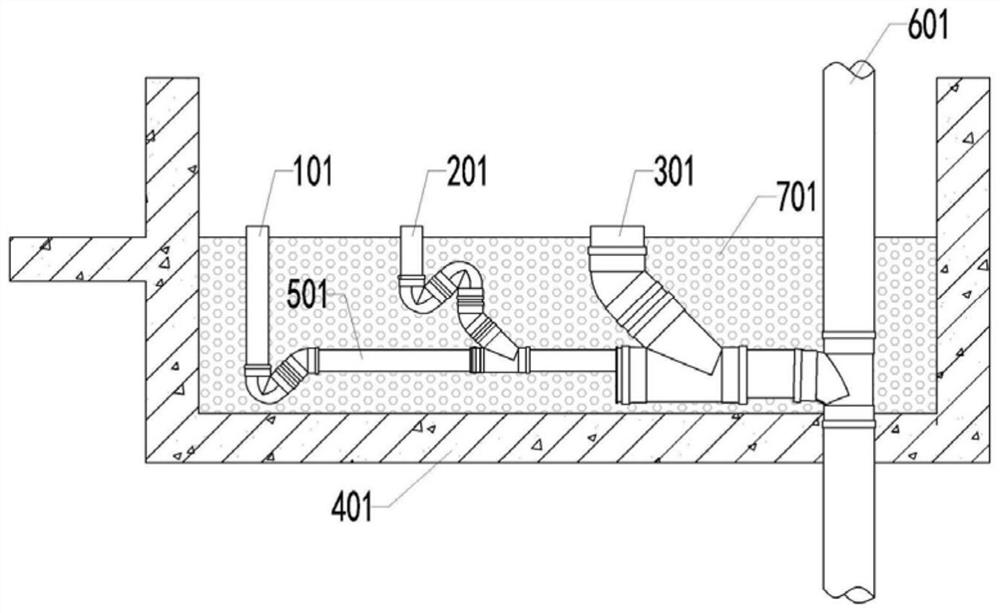

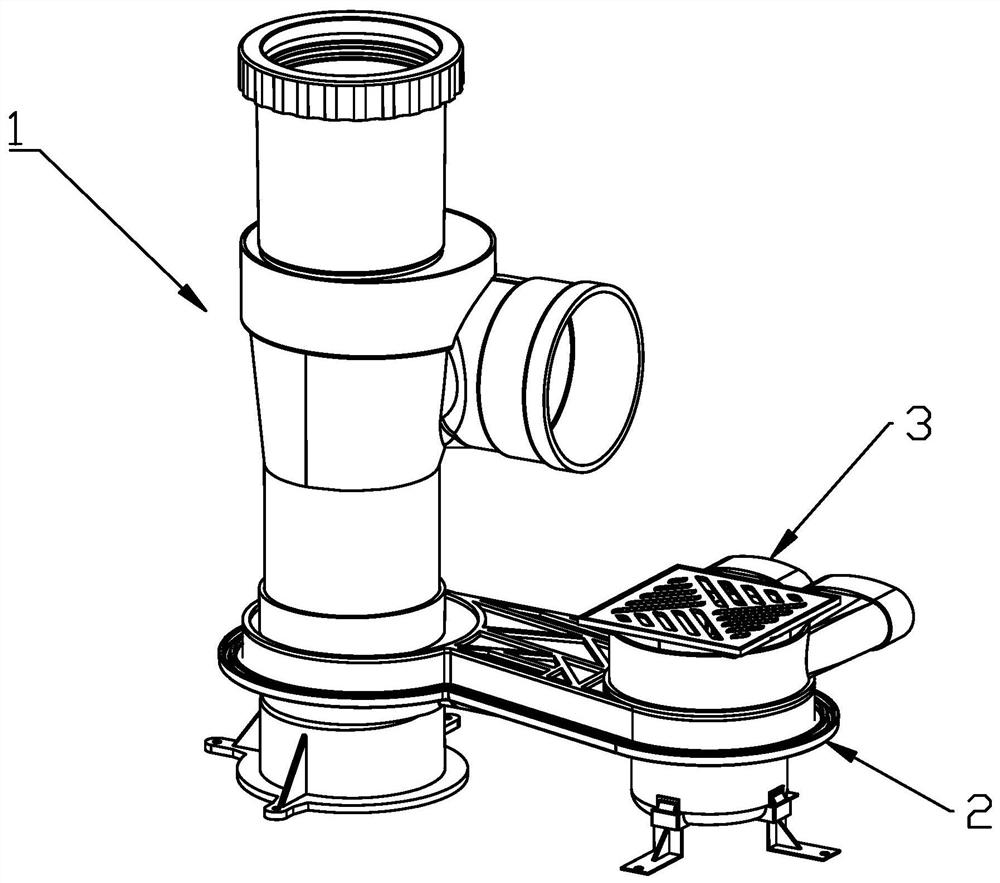

[0075] refer to Figure 3-16 , the present embodiment provides a building drainage collection system, said building drainage collection system is inscribed between the sewage main drainage pipes during actual installation, and communicates with the main sewage drainage pipes up and down. It includes a drain pipe assembly 1, a horizontal pipe drainage assembly 2 communicated with the drain pipe assembly 1, and a water seal assembly 3 communicated with the horizontal pipe drainage assembly 2. In this embodiment, the sewage refers to the water discharged from the toilet, and the waste water refers to the water discharged from the shower, washbasin and the like.

[0076] see Figure 3-Figure 10 The drain pipe assembly 1 includes a first water inlet pipe 11, a second water inlet pipe 12, a first standpipe 13 and a second standpipe 14; the first water inlet pipe 11 is connected to the second water inlet pipe 12 and internally communicated, and The inner edge of the second water in...

Embodiment 2

[0109] see Figure 18-20 , this embodiment only improves the positional relationship between the first filter screen 3223, the opening end 311 of the water storage part 31 and the inner wall of the second assembly part 22 in embodiment 1, and the rest of the structures and connection relationships are not adjusted.

[0110] The first filter screen 3223 is replaced by a check valve 5, the check valve includes a plurality of cover sheets 51, and the cover sheets 51 include a fan-shaped main body 511, and the fan-shaped main body 511 is away from the side of the fan-shaped circle center. The lower part is provided with a gravity block 512;

[0111] A cover plate support frame 52, a positioning bar 521 is arranged on the cover plate support frame 52, and the positioning bar 521 extends downward, and a stopper 522 is provided at the bottom end of the positioning bar 521;

[0112] The cover sheet 51 is rotatably mounted on the cover sheet support frame 52, and the cover sheet suppo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com