Turbine-driven circumferential sliding sleeve type pulse generation tool

A pulse generation and sliding sleeve technology, applied in the field of hydraulic fracturing tools, can solve the problems of poor reliability and easy clogging of the pressurization mechanism, and achieve the effect of good sealing reliability, not easy to clog, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

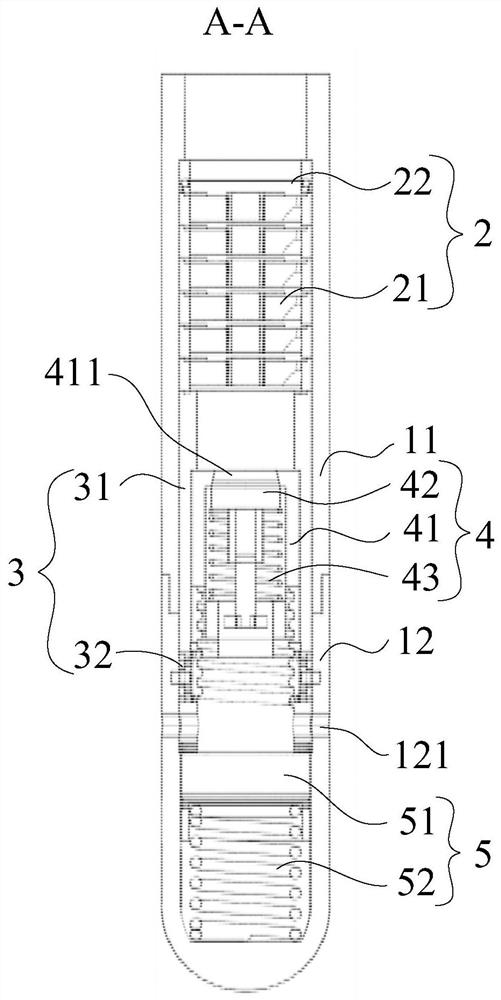

[0019] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, wherein the accompanying drawings constitute a part of the application and together with the embodiments of the present invention are used to explain the principle of the present invention and are not intended to limit the scope of the present invention.

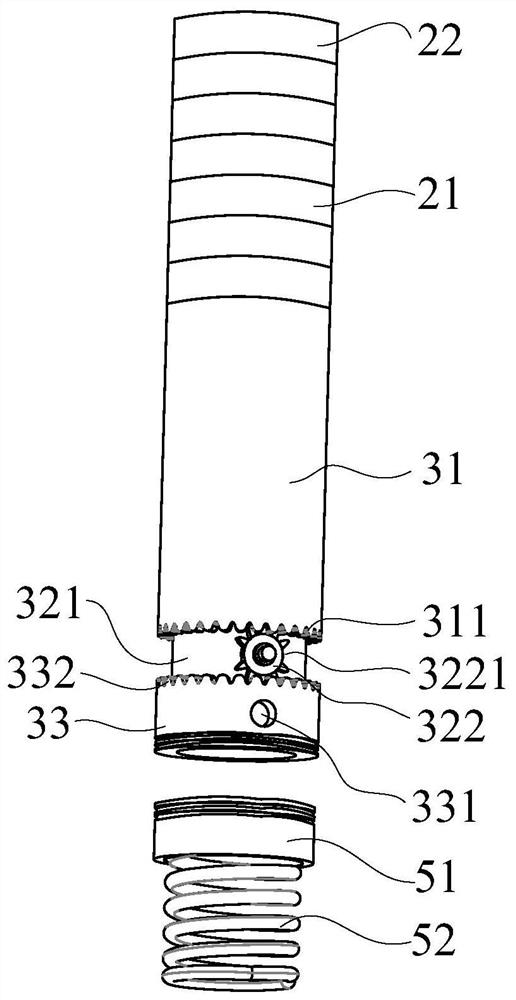

[0020] Please refer to Figure 1-Figure 6 , the present invention provides a turbine-driven circumferential sliding sleeve pulse generating tool, including a housing 1 , a turbine mechanism 2 , a transmission mechanism 3 and a check valve 4 .

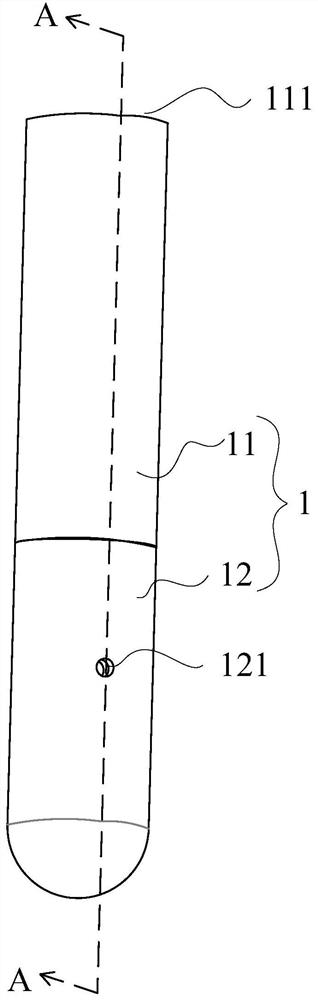

[0021] Please refer to figure 1 with figure 2 , the housing 1 has a cylindrical airtight cavity, the housing 1 has a female button end processed with a female button 111, and the side wall of the housing 1 is provided with a hole communicating with the cavity. 121 of the perforations.

[0022] Please refer to figure 1 with figure 2 , the turbo m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com