Multilayer functional gradient vertical shaft wall structure and construction process

A technology with functional gradient and layer structure, which is applied in sinking, shaft equipment, shaft lining, etc., can solve the problems of rubber and other materials aging, poor water sealing, and complex shaft wall composition, so as to reduce the inner stress concentration and strengthen the overall sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

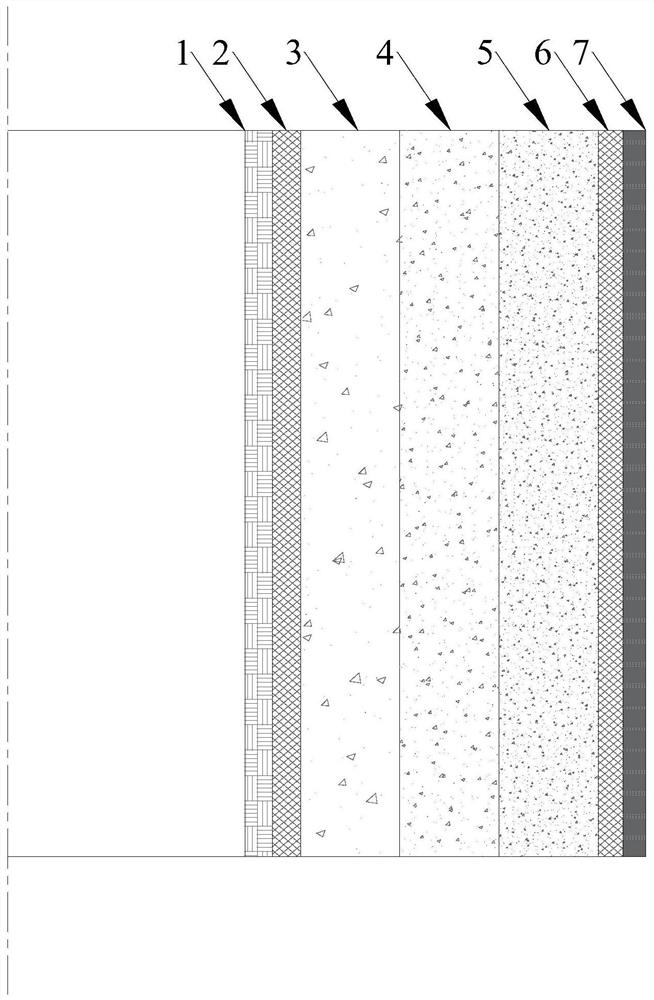

[0064] Such as figure 1As shown, a multi-layer functional gradient shaft wall structure is mainly composed of a fire-resistant layer 1, an inner anti-seepage layer 2, an inner layer anti-water pressure layer structure layer 3, an intermediate layer anti-water pressure layer structure layer 4, and an outer layer The water pressure-resistant layer structure layer 5, the outer layer impermeable layer 6, and the anti-corrosion layer 7; the elastic modulus of the concrete of different water pressure-resistant layer structure layers is ranked as the outer layer anti-water pressure layer structure layer 5 > the middle layer anti-water pressure Structural layer 4> Inner layer anti-water pressure layer structural layer 3; fire-resistant layer concrete is high-temperature-resistant concrete, impermeable layer is high-impermeability concrete, and anti-corrosion layer is anti-corrosion concrete; according to the design strength of the shaft wall structure, according to the specification D...

Embodiment 2

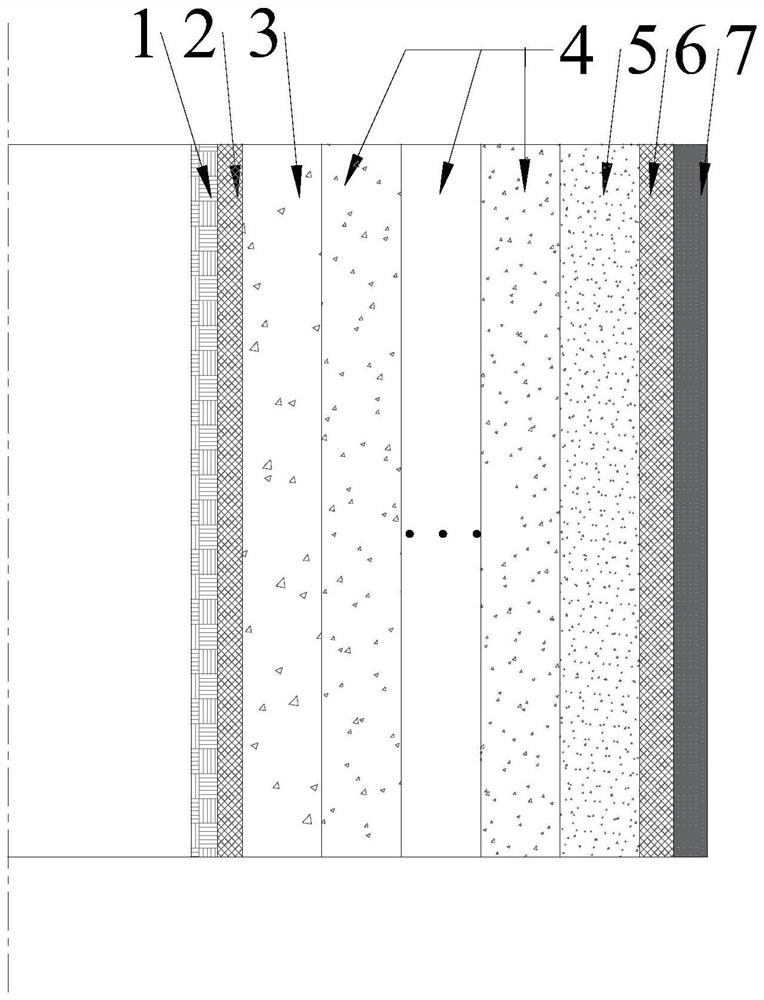

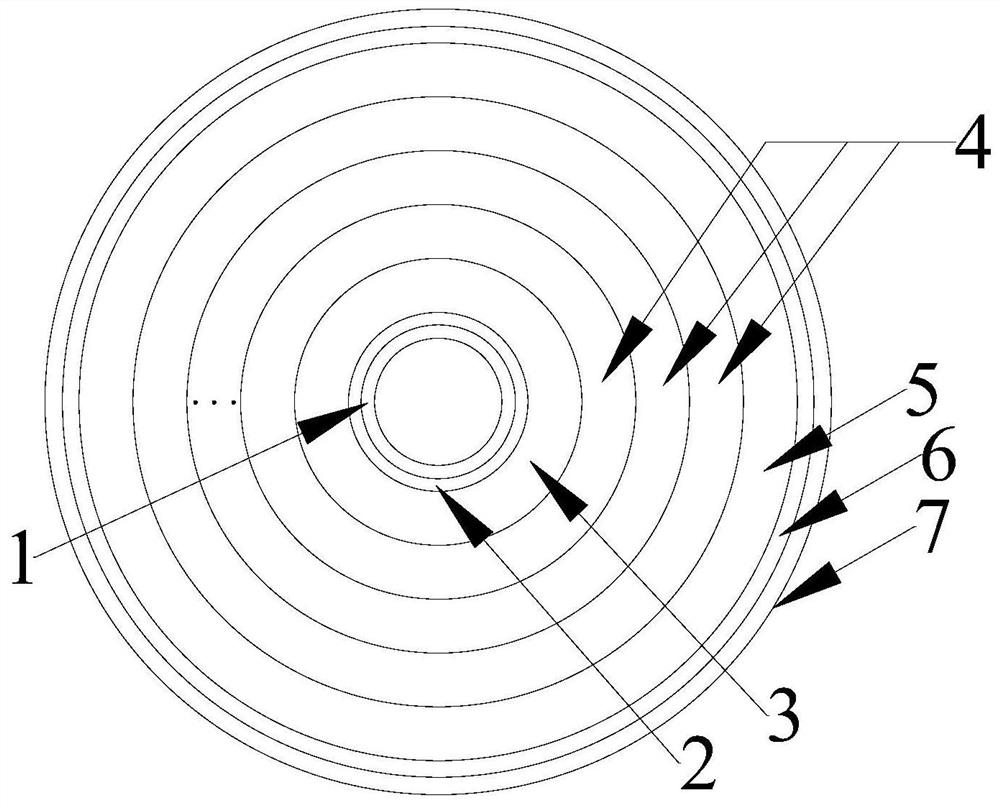

[0067] Such as figure 2 , image 3 As shown, a multi-layer functional gradient shaft wall structure of the present invention is mainly composed of a fire-resistant layer 1, an inner anti-seepage layer 2, an inner layer anti-water pressure layer structure layer 3, and an intermediate layer water pressure-resistant layer structure layer 4 1. The outer layer anti-water pressure layer structure layer 5, the outer layer impermeable layer 6, and the anti-corrosion layer 7 are composed. Wherein, the middle layer anti-water pressure layer structure layer 4 is multi-layered, and the modulus of elasticity decreases from outside to inside. Each layer of concrete structure is the same concrete material, which has the same physical parameters such as elastic modulus and compressive strength. The concrete material of the concrete structure layer needs to be formulated according to the formula. The fire-resistant layer concrete is high-temperature-resistant concrete, the impermeable laye...

Embodiment 3

[0069] Such as Figure 4 As shown, a multi-layer functional gradient shaft wall structure of the present invention mainly consists of a fire-resistant layer 1, an inner anti-seepage layer 2, an inner layer anti-water pressure layer structure layer 3, and an outer layer water pressure-resistant layer structure layer 5 , Outer anti-permeability layer 6, anti-corrosion layer 7 composition. The structural layer of the anti-water pressure layer consists of two layers, and the elastic modulus decreases from the outside to the inside. The elastic modulus of concrete is changed by adding polypropylene fiber, basalt fiber, carbon fiber and steel fiber, and the fluidity of concrete material is increased by adding water reducing agent. The fire-resistant layer concrete is high-temperature-resistant concrete, the impermeable layer is high-impermeability concrete, and the anti-corrosion layer is corrosion-resistant concrete. The shaft wall structure needs to prepare five functionally gra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com