Primary support structure of tunnel steel pipe arches and support method of primary support structure

A technology of primary support and steel pipe arch, applied in tunnels, tunnel linings, earthwork drilling and mining, etc., can solve problems such as project cost waste, achieve the effects of reducing project waste, creating economic benefits, and optimizing structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

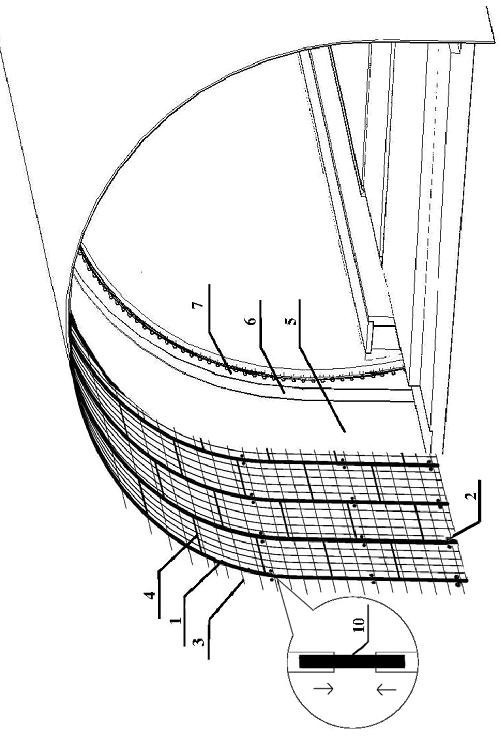

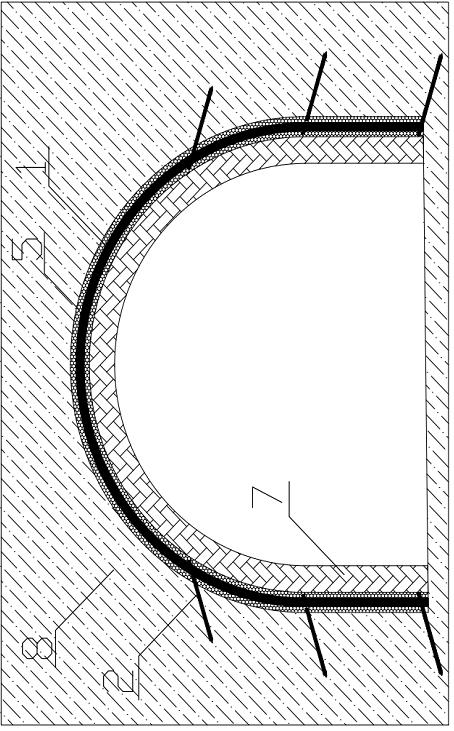

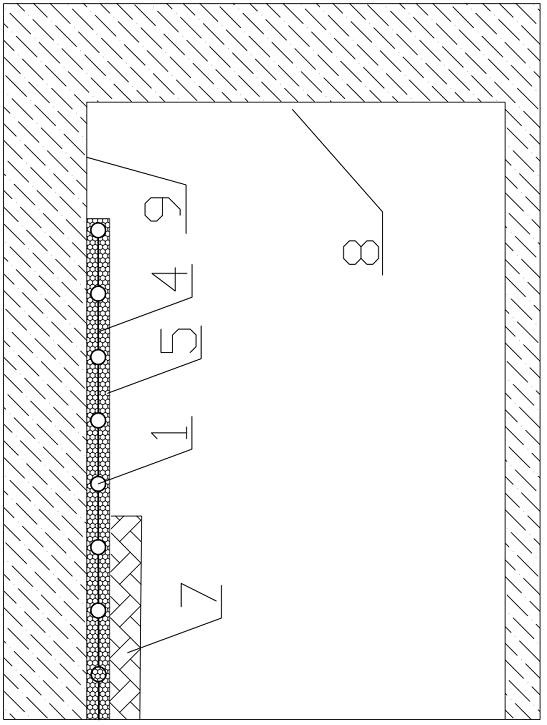

[0034] Such as Figure 1~3 As shown, a tunnel steel pipe arch primary support structure, the structure includes several sections of steel pipe arch 1 laid on the surrounding rock 8 of the tunnel face and connected together by connecting steel bars 4, and the surrounding rock 9 surface of the free face The steel mesh sheet 3 on the top.

[0035] Each section of steel pipe arch 1 is formed by connecting several seamless steel pipes through socketed steel bars 10; a pair of locking foot anchor pipes 2 are respectively provided at the top of the steel pipe arch 1 and at the waist and foot of the arch; Steel mesh 3; steel pipe arch 1, steel mesh 3, connecting steel bar 4 and anchor pipe 2 are provided with primary lining shotcrete 5, and the primary lining shotcrete 5 is successively provided with waterproof board 6 and secondary lining 7.

[0036] Wherein: the socketed steel bar 10 is a Φ25 steel bar with a length of 40cm, and one end extends into the seamless steel pipe, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com