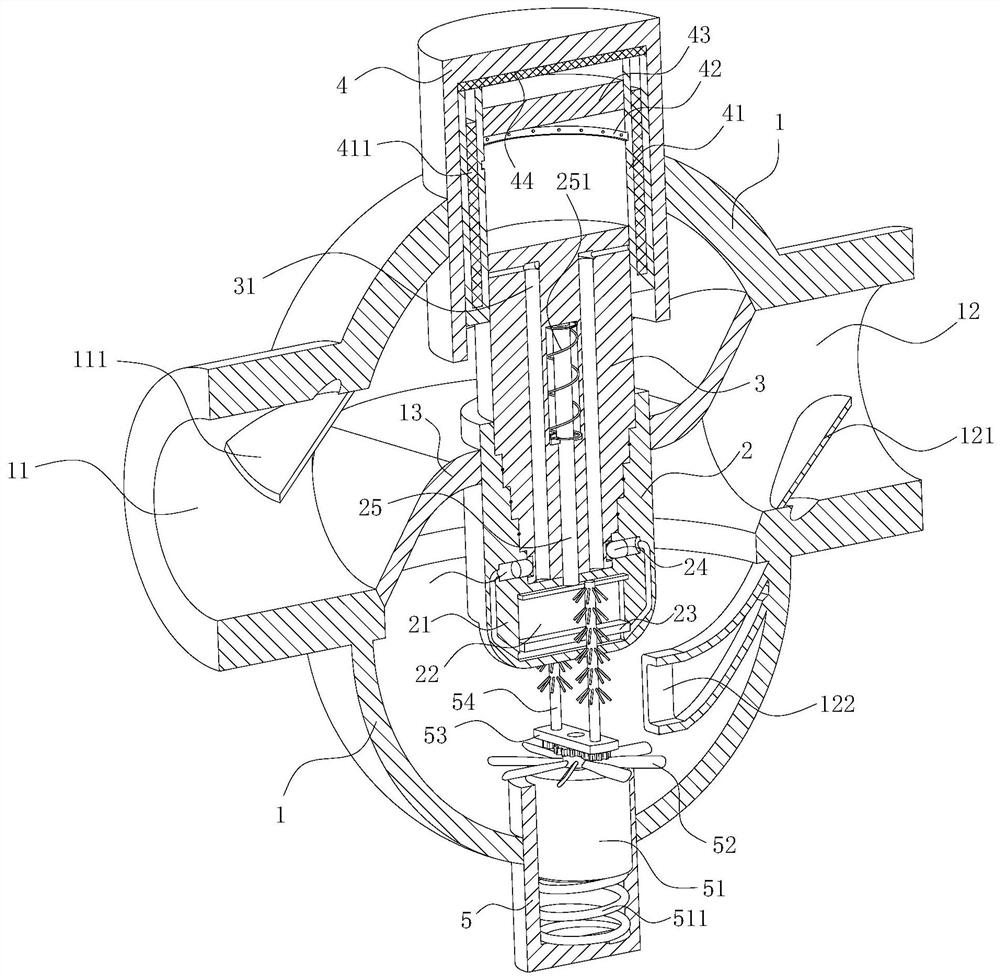

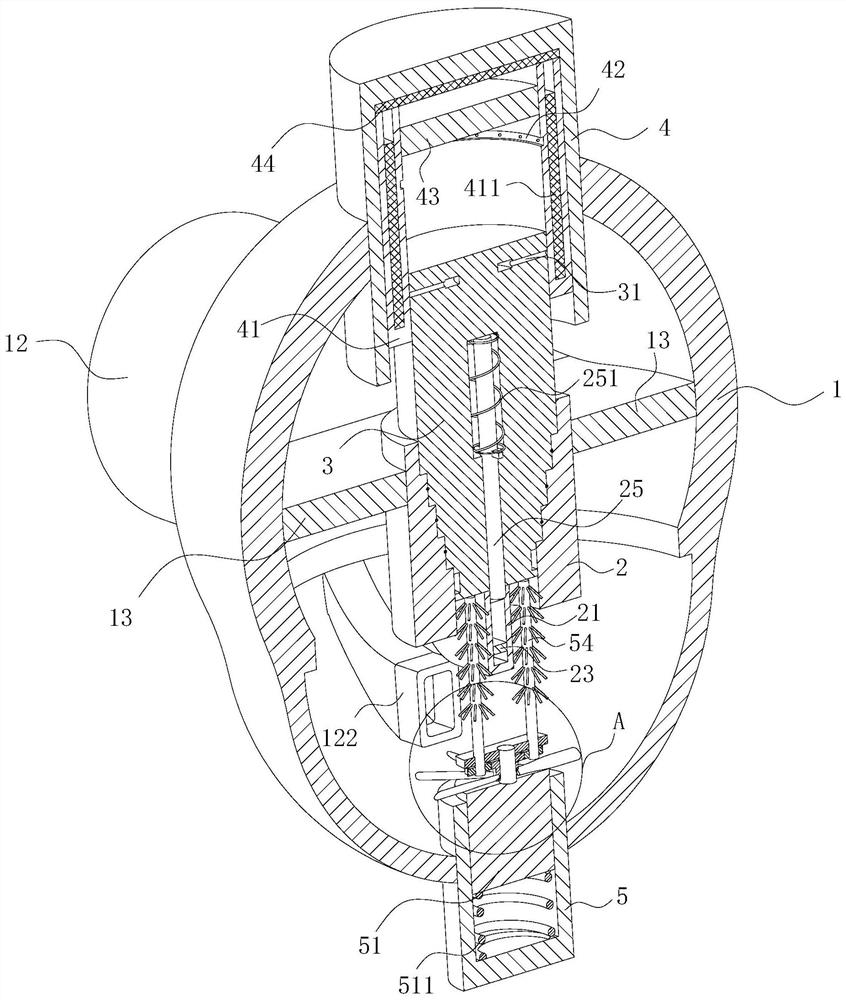

Bidirectional electromagnetic valve

A two-way solenoid valve and valve body technology, applied in the field of solenoid valves, can solve problems such as unreliable work, medium leakage, and increased production costs, and achieve the effects of increasing the effective working surface area, ensuring reliability, and improving sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

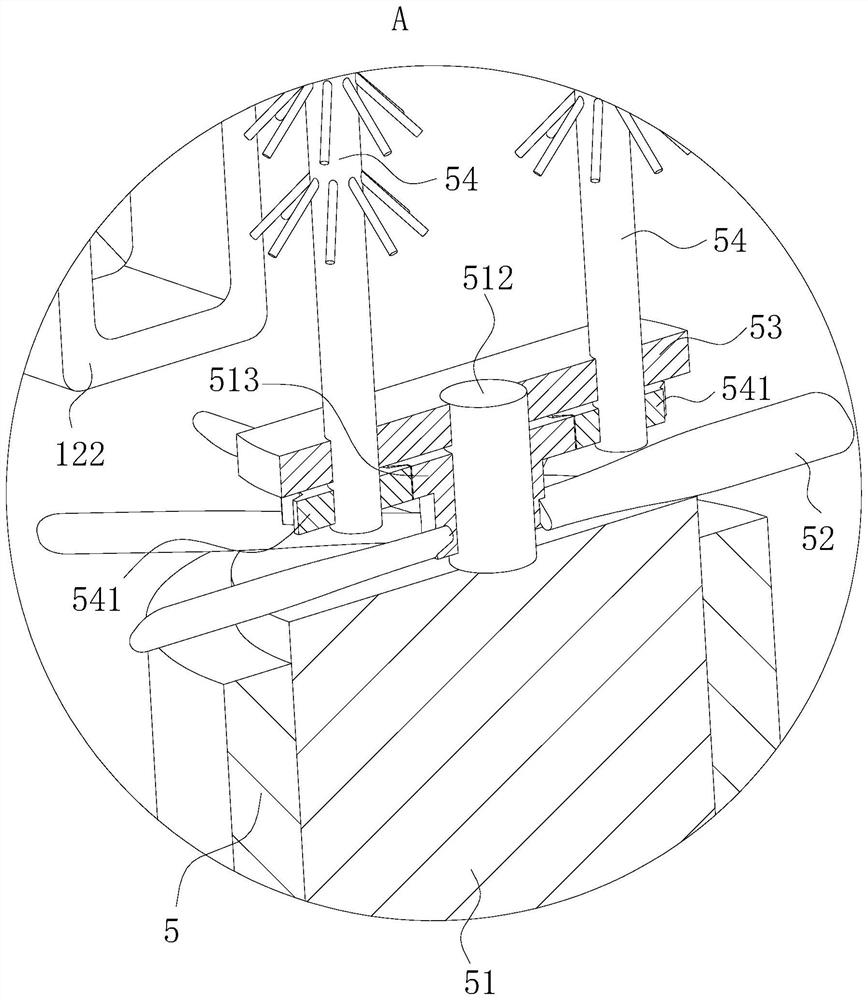

Method used

Image

Examples

Embodiment approach

[0038] As an embodiment of the present invention, a sealing ring is arranged on the stepped spool 3; the sealing ring is located on the side of the stepped step at the lower end of the stepped spool 3; between 2;

[0039] When working, when the solenoid valve is connected to the power supply of the coil 411 by the controller, and the stepped valve core 3 is pushed and inserted into the stepped seat 2, the sealing ring provided on the side of the stepped step on the stepped valve core 3 and the step in the stepped seat 2 The side surfaces of the stepped steps contact each other, thereby improving the sealing performance between the stepped valve core 3 and the stepped seat 2. At the same time, the sealing ring can ensure that the wear between the stepped valve core 3 and the stepped seat 2 is serious for a long time, resulting in After the gap between the two is increased, the sealing ring can still ensure that the sealing between the two is on the qualified line, effectively p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com