Low-nitrogen water tube boiler saving energy and bearing pressure

A water-tube boiler and boiler body technology, which is applied in water-tube steam boilers, boiler water tubes, steam boilers, etc., can solve the problems of water-cooled tube bundles that are prone to carbon deposition and blockage, difficult to clean, and inconvenient to maintain the furnace body. The effect of large burner power and improvement of average heat transfer coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The patent will be described in detail below with reference to the accompanying drawings and specific embodiments.

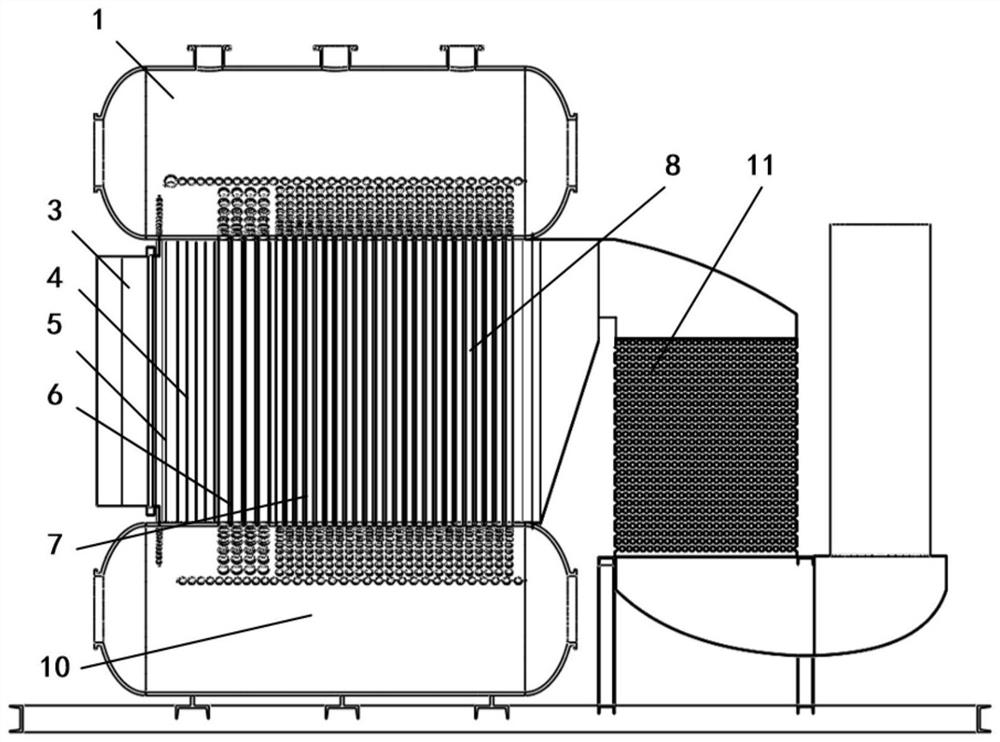

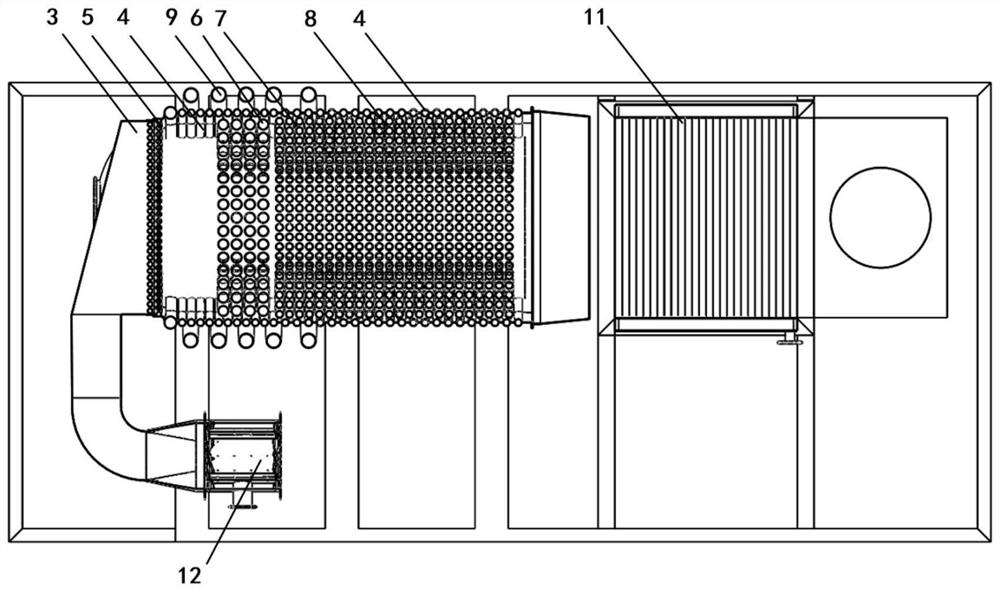

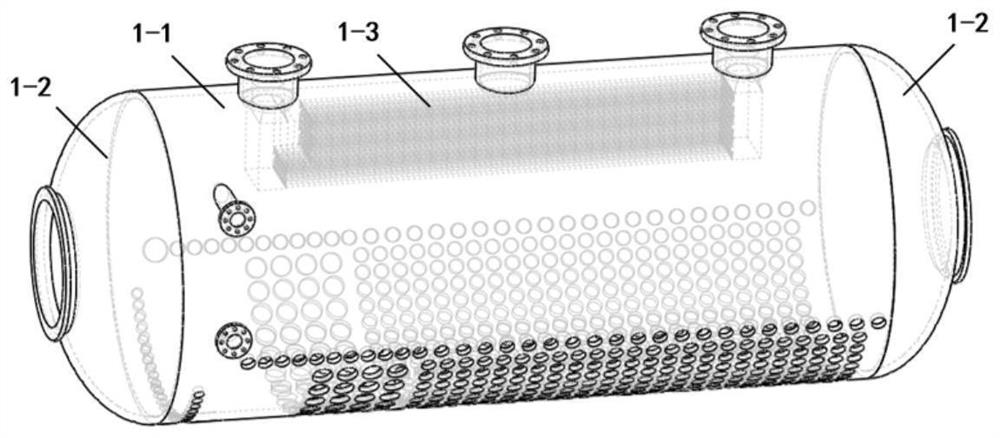

[0034] like Figure 1a and Figure 1b As shown in the figure, a high-efficiency and low-nitrogen pressurized water-tube boiler of the present invention includes an upper drum 1, a casing, a burner distribution head 3, a membrane-type water-cooled wall tube bundle 4, a water-cooled flame tube bundle 5, a radiant tube bundle 6, a high-temperature convection tube bundle 7, Low temperature convection tube bundle 8, descending tube bundle 9, lower drum 10, external condenser 11, pre-mixer 12 and supporting fans, feed water pumps, gas valve groups, controllers, etc. The burner distribution head (3), membrane type water-cooled wall tube bundle (4), water-cooled flame tube bundle (5), radiant tube bundle (6), high temperature convection tube bundle (7), low temperature convection tube bundle (8), descending tube bundle (9) ) are located between the upper drum (1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com