Vehicle body welding spot defect detection device and method based on STFT time-frequency analysis

A technology of defect detection and time-frequency analysis, which is applied to measuring devices, analyzing materials, and analyzing solids using sound waves/ultrasonic waves/infrasonic waves, etc. It can solve problems such as low artificial timeliness and incomplete detection information, and achieve long-term detection and operation. Simple, Accuracy-Enhancing Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

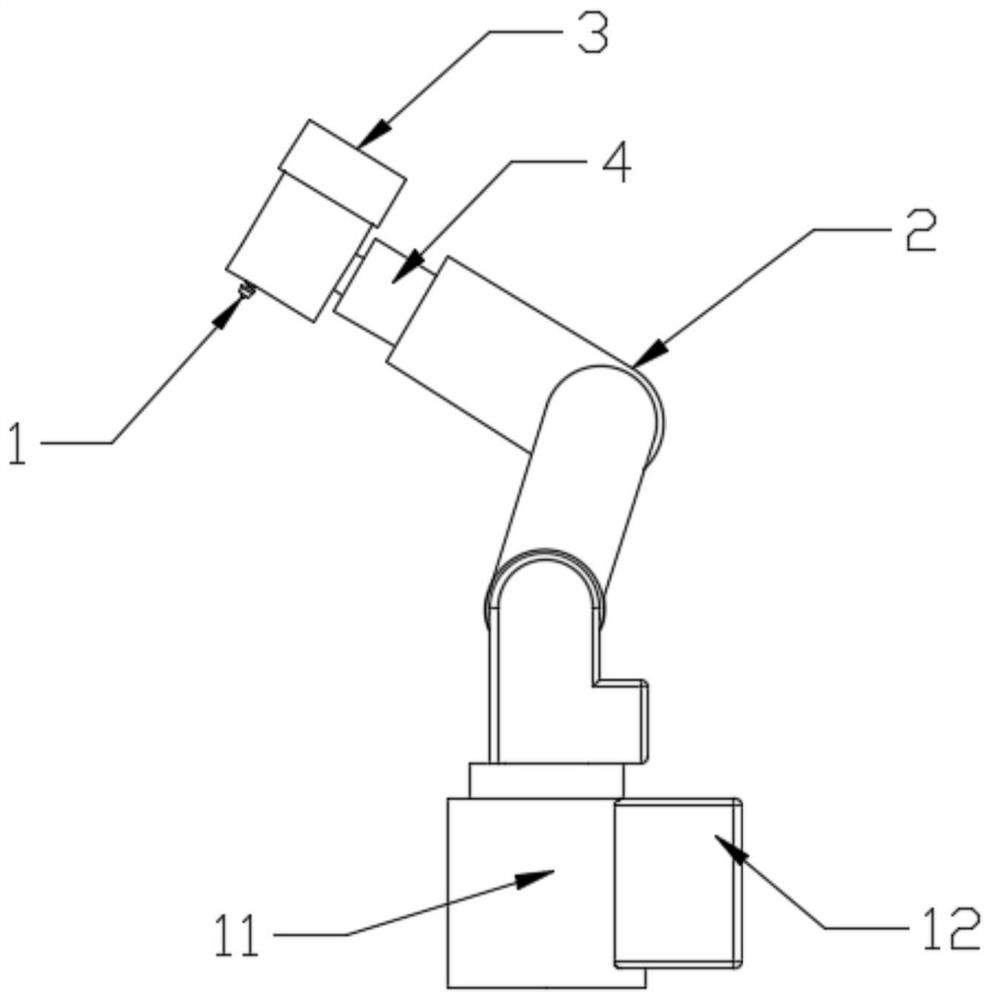

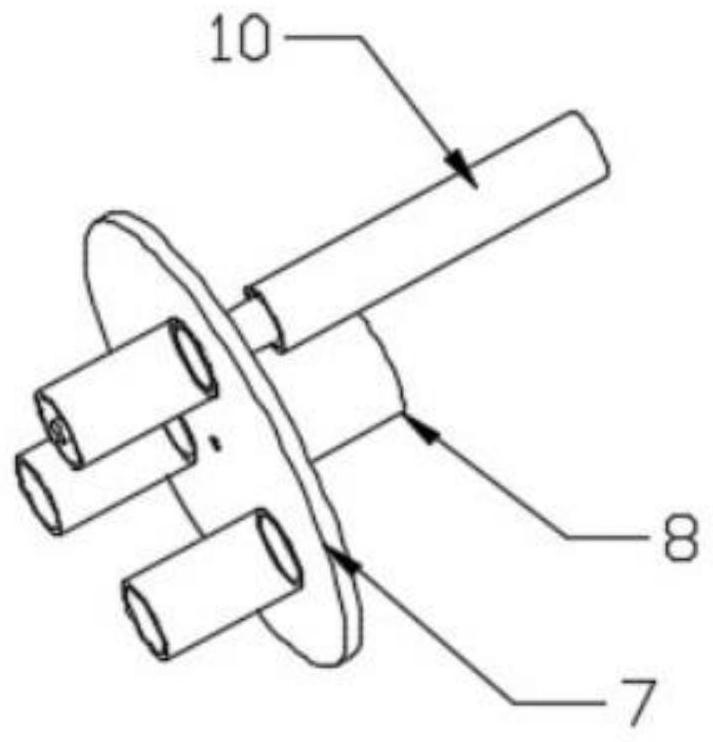

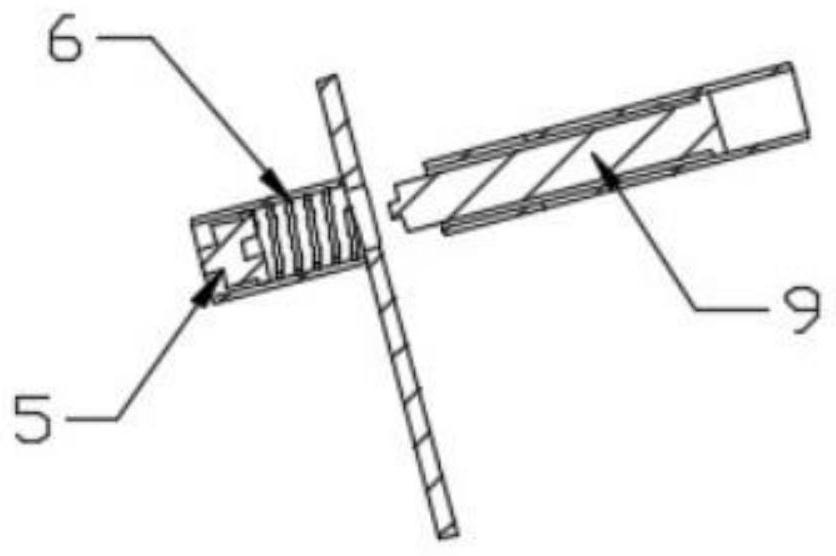

[0039] Such as figure 1 , figure 2 and image 3 As shown, a vehicle body solder joint defect detection device based on STFT time-frequency analysis includes an ultrasonic detection module 1, a six-degree-of-freedom robot 2, a hydraulic pump and a hydraulic oil reservoir 3, an ultrasonic generator 4, an ultrasonic probe 5, and a return spring 6. Rotary disk 7, motor 8, push rod 9, hydraulic cylinder 10, control module 11, upper computer 12. The ultrasonic detection module 1 is located in front of the upper part of the six-degree-of-freedom robot 2 . The hydraulic pump and hydraulic oil reservoir 3 are located behind the upper part of the six-degree-of-freedom robot 2 and are connected to the ultrasonic detection module 1 . The ultrasonic generator 4 is located at the connection between the ultrasonic detection module 1 and the six-degree-of-freedom robot 4 . The ultrasonic probe 5, return spring 6, rotating disc 7, motor 8, push rod 9, hydraulic cylinder 10, etc. are built...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com