A kind of thin film piezoelectric acoustic wave filter and its manufacturing method

A piezoelectric sound wave and manufacturing method technology, applied in the direction of electrical components, impedance networks, etc., can solve the problems of low reliability of the packaging process, thick cavity filter, poor cover stability, etc., to achieve low cost and reduced structural strength , the effect of size reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

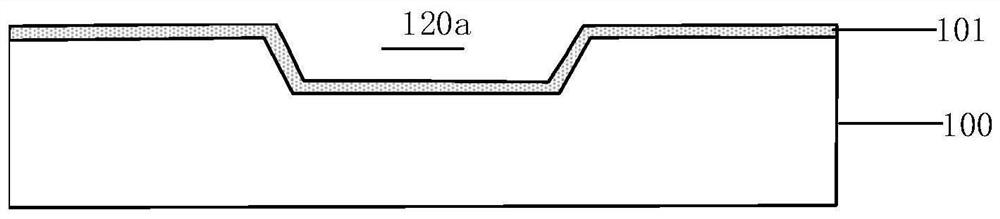

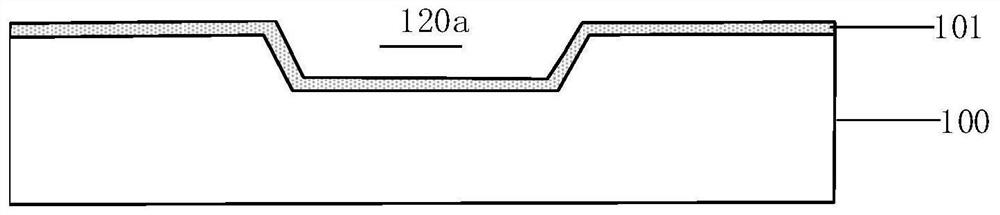

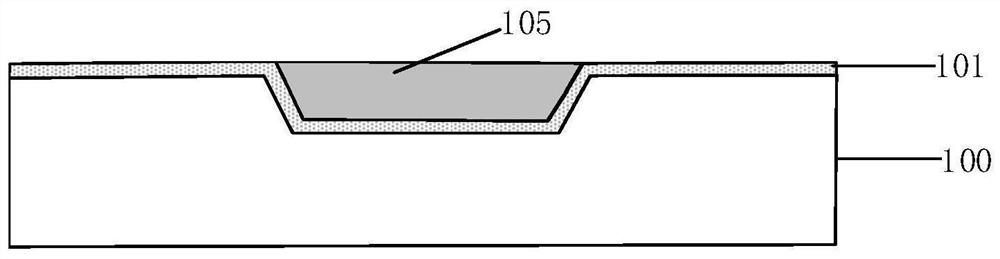

[0081] This embodiment provides a thin film piezoelectric acoustic wave resonator, Figure 13 A schematic diagram of the structure of the thin film piezoelectric acoustic wave resonator in this embodiment is shown, refer to Figure 13 , thin-film piezoelectric acoustic resonators include:

[0082] The first substrate 100, the upper surface of the first substrate 100 is provided with a plurality of mutually isolated first cavities 120a, and the mutually isolated parts of the adjacent first cavities 120a are made of semiconductor material;

[0083] The piezoelectric laminated structure is disposed on the upper surface of the first substrate 100 to cover the first cavity 120a, and the piezoelectric laminated structure includes a first electrode 102 and a piezoelectric layer stacked in sequence from bottom to top 103 and the second electrode 104;

[0084] The acoustic wave resonator unit is composed of the piezoelectric laminated structure above the first cavity 120a, and the bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com