System and method for improving denitrification of MSBR process

A denitrification and process technology, which is applied in the system field of improved MSBR process denitrification, can solve the problems of affecting effluent water quality and poor denitrification effect, so as to improve nitrification reaction efficiency and organic matter removal efficiency, increase hydraulic retention time, increase The effect of microbial biomass

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The method that the system for improving MSBR process denitrification provided by the present invention carries out denitrification is:

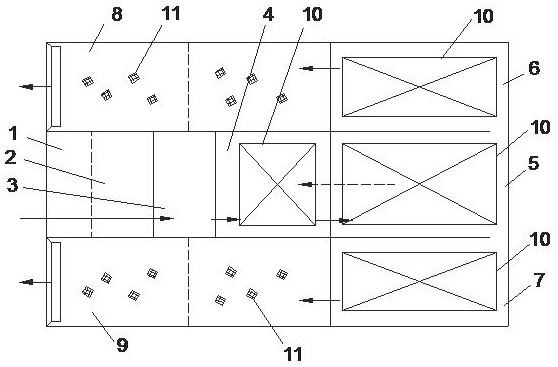

[0031] The sewage enters the anaerobic zone 3 through the water inlet pipe, and at the same time, the sludge lift pump lifts the sludge in the pre-anoxic zone 1 to the anaerobic zone 3, and the effluent from the anaerobic zone 3 enters the anoxic zone I zone 4, and the anoxic zone I zone 4 effluent Enter the anoxic zone II zone 5, and the effluent from the anoxic zone II zone 5 enters the aerobic zone 1 zone 6 and the aerobic zone II zone 7 respectively through the outlet, and the nitrifying liquid in the aerobic zone 1 zone 6 and the aerobic zone II zone 7 flows back through the nitrifying liquid return pipe To anoxic zone I zone 4, the effluent from aerobic zone I zone 6 enters SBBR I zone 8, the effluent from aerobic zone II zone 7 enters SBBR II zone 9, and the remaining sludge from SBBR I zone 8 and SBBR II zone 9 flows back to pr...

Embodiment 2

[0034] The method that the system for improving MSBR process denitrification provided by the present invention carries out denitrification is:

[0035]The sewage enters the anaerobic zone 3 through the water inlet pipe, and at the same time, the sludge lift pump lifts the sludge in the pre-anoxic zone 1 to the anaerobic zone 3, and the effluent from the anaerobic zone 3 enters the anoxic zone I zone 4, and the anoxic zone I zone 4 effluent Enter the anoxic zone II zone 5, and the effluent from the anoxic zone II zone 5 enters the aerobic zone 1 zone 6 and the aerobic zone II zone 7 respectively through the outlet, and the nitrifying liquid in the aerobic zone 1 zone 6 and the aerobic zone II zone 7 flows back through the nitrifying liquid return pipe To anoxic zone I zone 4, the effluent from aerobic zone I zone 6 enters SBBR I zone 8, the effluent from aerobic zone II zone 7 enters SBBR II zone 9, and the remaining sludge from SBBR I zone 8 and SBBR II zone 9 flows back to pre...

Embodiment 3

[0038] The method that the system for improving MSBR process denitrification provided by the present invention carries out denitrification is:

[0039] The sewage enters the anaerobic zone 3 through the water inlet pipe, and at the same time, the sludge lift pump lifts the sludge in the pre-anoxic zone 1 to the anaerobic zone 3, and the effluent from the anaerobic zone 3 enters the anoxic zone I zone 4, and the anoxic zone I zone 4 effluent Enter the anoxic zone II zone 5, and the effluent from the anoxic zone II zone 5 enters the aerobic zone 1 zone 6 and the aerobic zone II zone 7 respectively through the outlet, and the nitrifying liquid in the aerobic zone 1 zone 6 and the aerobic zone II zone 7 flows back through the nitrifying liquid return pipe To anoxic zone I zone 4, the effluent from aerobic zone I zone 6 enters SBBR I zone 8, the effluent from aerobic zone II zone 7 enters SBBR II zone 9, and the remaining sludge from SBBR I zone 8 and SBBR II zone 9 flows back to pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com