Non-methane total hydrocarbon on-line monitoring device and monitoring method

A non-methane total hydrocarbon and monitoring device technology, applied in the detection field, can solve the problems of inaccurate detection, inconvenient remote transportation, and low degree of automation, and achieve the effects of fast and accurate detection, convenient remote transportation, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

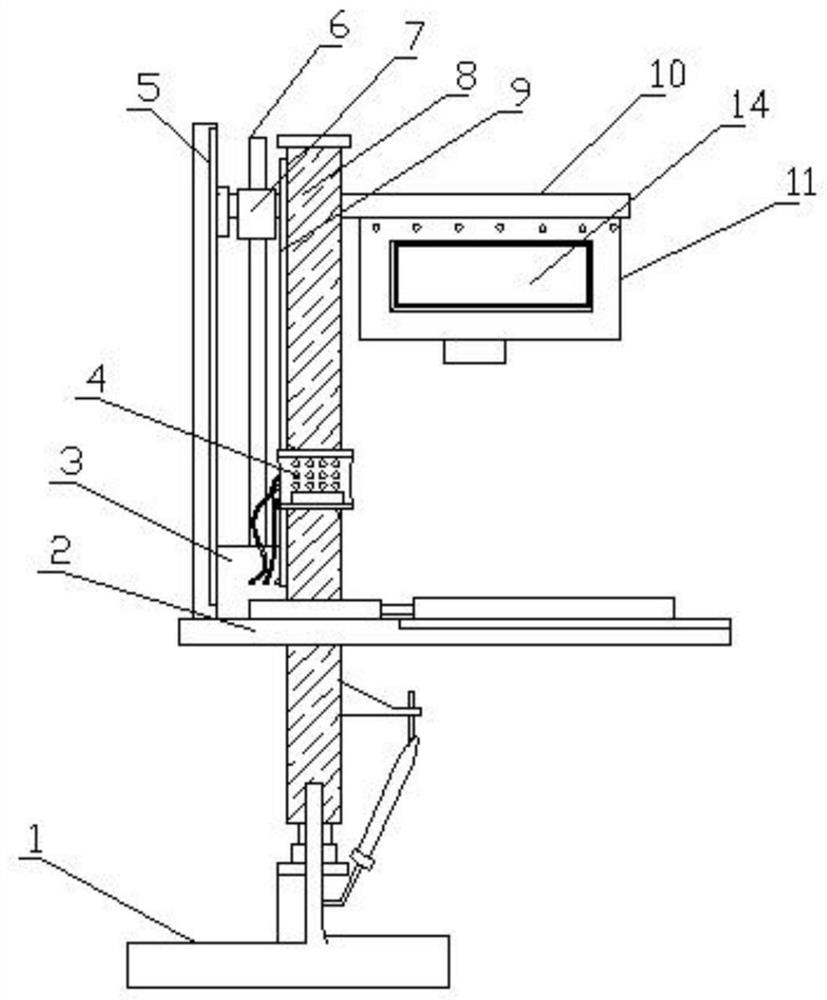

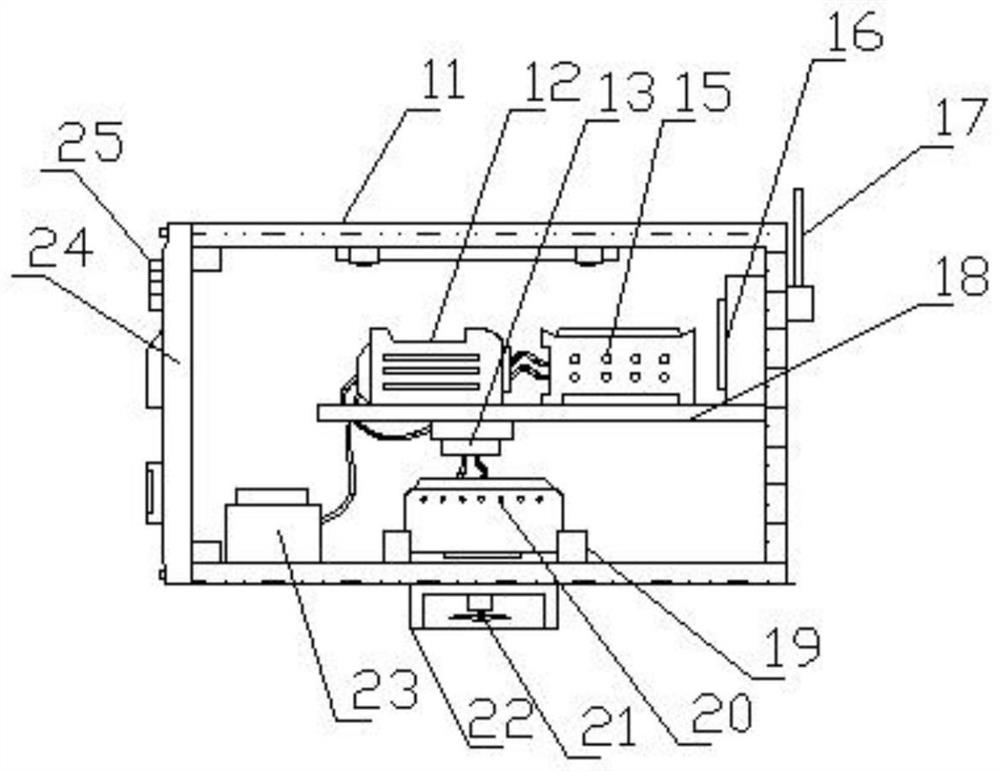

[0029] An online monitoring device for non-methane total hydrocarbons, comprising a base 1 and a support column 8, the top of the base 1 is equipped with a support column 8 through bolts, and the bottom end of the support column 8 is equipped with a bearing plate 2 through bolts, the One end of the top of the bearing plate 2 is installed with a servo motor 3 through a mounting seat, the output shaft of the servo motor 3 is connected with a screw 6 through a coupling, and the top end of the screw 6 is sleeved with a wire block 7, and the support A slide groove 9 runs through the column 8, and a top plate 10 runs through the slide groove 9, and one end of the top plate 10 is welded on one side of the wire block 7, and the bottom of the top plate 10 is equipped with a detection housing 11 by bolts, so One side of the detection housing 11 is equipped with a display screen 14 through the installation groove and rubber sealing strip, and the inner bottom of the detection housing 11 i...

Embodiment 2

[0047] An online monitoring device for non-methane total hydrocarbons, comprising a base 1 and a support column 8, the top of the base 1 is equipped with a support column 8 through bolts, and the bottom end of the support column 8 is equipped with a bearing plate 2 through bolts, the One end of the top of the bearing plate 2 is installed with a servo motor 3 through a mounting seat, the output shaft of the servo motor 3 is connected with a screw 6 through a coupling, and the top end of the screw 6 is sleeved with a wire block 7, and the support A slide groove 9 runs through the column 8, and a top plate 10 runs through the slide groove 9, and one end of the top plate 10 is welded on one side of the wire block 7, and the bottom of the top plate 10 is equipped with a detection housing 11 by bolts, so One side of the detection housing 11 is equipped with a display screen 14 through the installation groove and rubber sealing strip, and the inner bottom of the detection housing 11 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com