Device and system for detecting power transmission tower node quality based on laser

A technology for laser detection and transmission towers, applied in measurement devices, radio wave measurement systems, optical devices, etc., can solve the problem that the transmission tower can withstand wind and earthquake magnitudes, reduce the bearing capacity of transmission tower nodes, and loosen, fall off or even damage the bolts and other problems, to achieve the effect of fast detection speed, reliable installation and fixation, and avoidance of errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

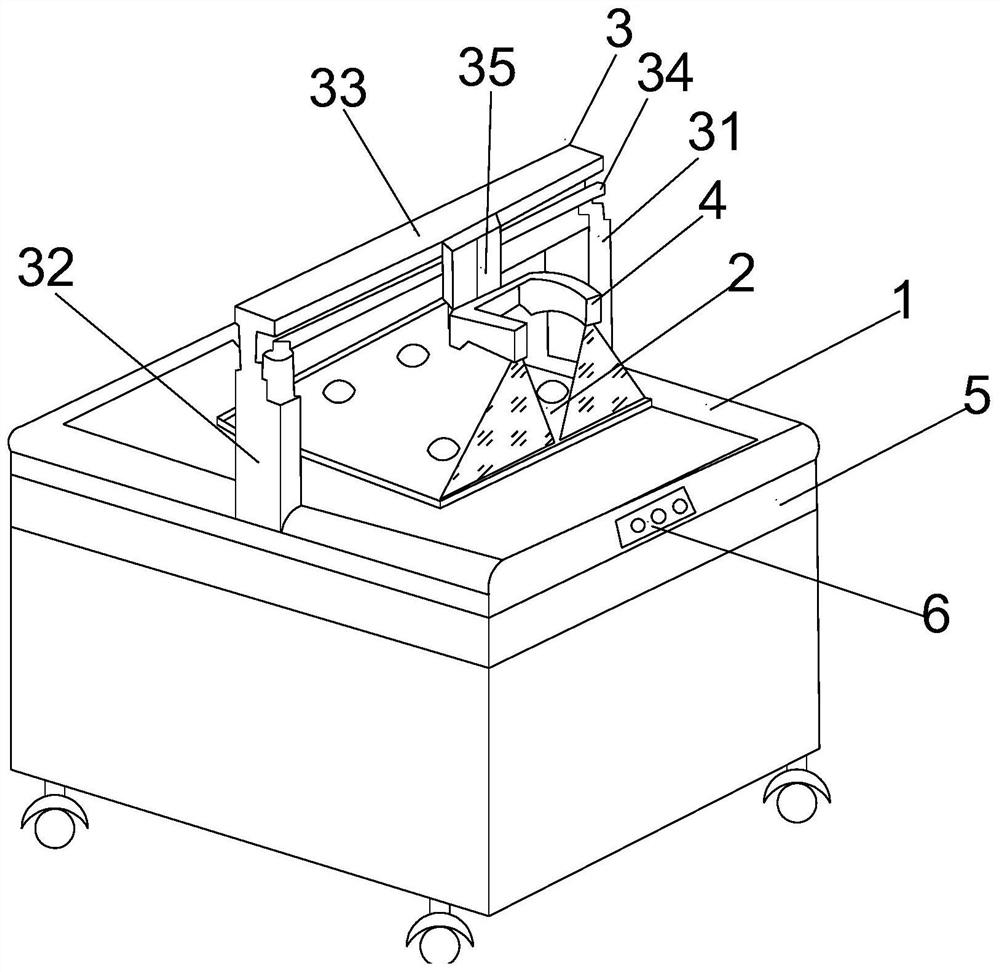

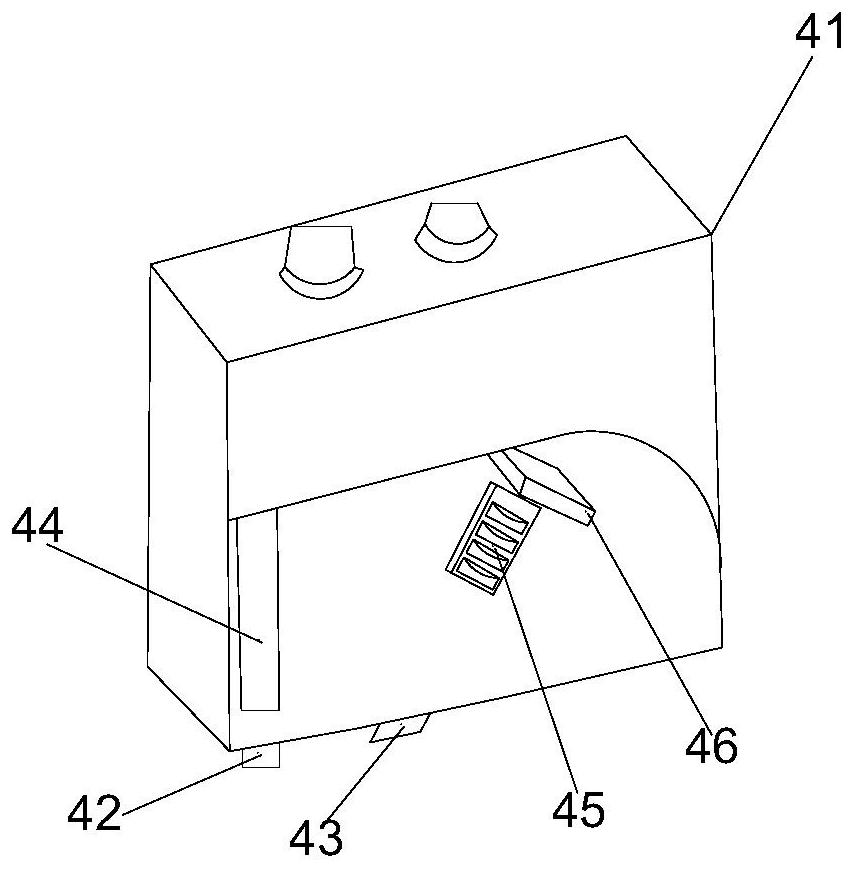

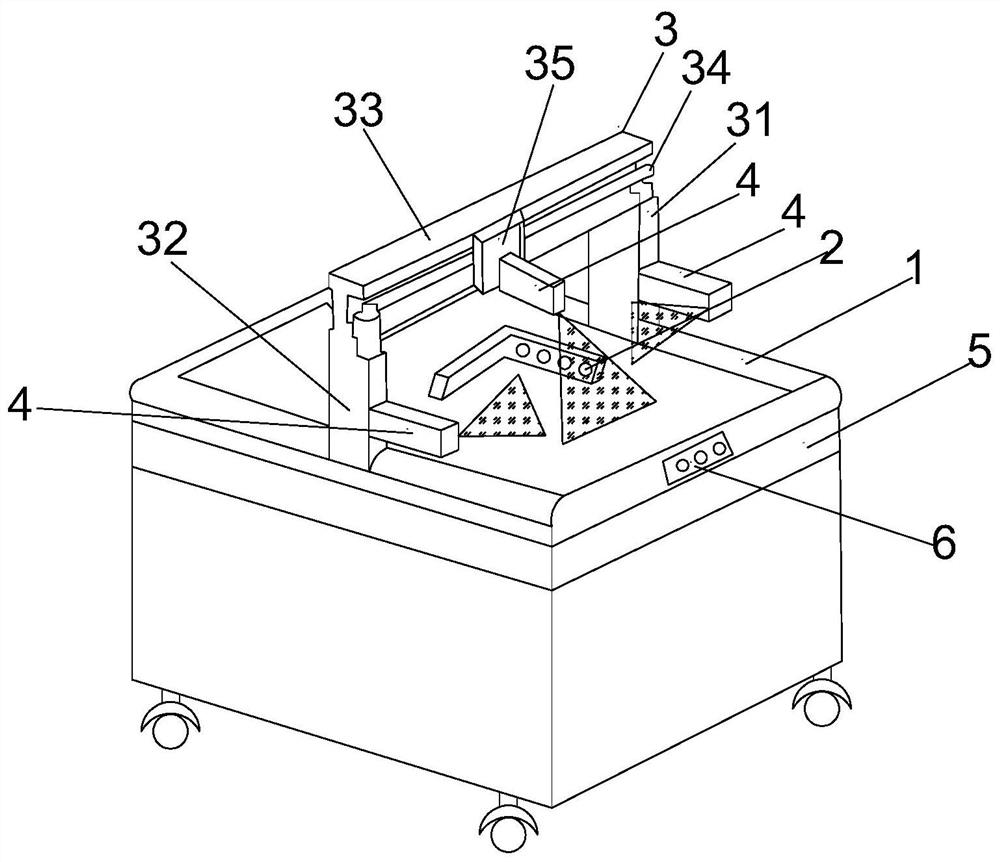

[0040] like figure 1 and figure 2 As shown, the present invention is a device for detecting the quality of transmission tower nodes based on laser, which includes a workbench 1 and a component to be detected 2. A gantry 3 is erected, and a laser detector 4 is installed on the gantry 3. The working surface is connected with a drive device 5 that drives the horizontal movement of the parts to be detected 2. 2. The moving direction is vertical. When the component to be detected 2 moves to the bottom of the laser detector 4, the laser detector 4 works, and the scanning area of the laser detector 4 covers the component to be detected 2. There is an equipment control device inside the workbench 1, and the equipment control device Control the driving device 5 and then control the movement range of the parts to be detected 2 on the surface of the working surface; the laser detector 4 includes a laser detector 4 box body, and the laser detector 4 box body is provided with a light s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com