Equipment maintenance prompting method and device, equipment and storage medium

A kind of equipment maintenance and equipment technology, applied in the electronic field, can solve the problems that affect the use effect and service life of the equipment, fail to check and maintain the equipment in time, manual maintenance is prone to mistakes, etc., and achieve the effect of improving the use effect and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

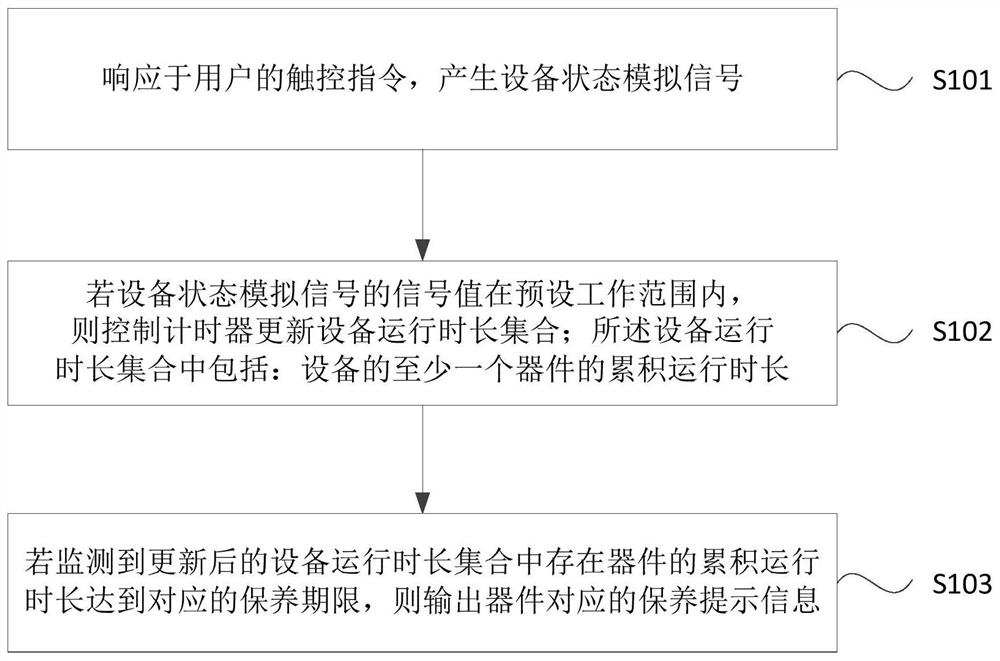

[0026] figure 1 It is a flow chart of an equipment maintenance reminder method provided by Embodiment 1 of the present invention. This embodiment can be applied to the situation of reminding any kind of equipment maintenance including the upper computer and the lower computer. For example, it can be a PCB drill The situation where the maintenance of the hole milling machine is prompted. The method can be implemented by an equipment maintenance prompting device or equipment, and the device can be implemented in the form of software and / or hardware. The method specifically includes the following steps:

[0027] S101. Generate a device state simulation signal in response to a user's touch command.

[0028] Among them, the user's touch command can refer to the command generated by the user by triggering a physical button on the device (such as a PCB drilling and edge milling machine), or a virtual button on the device display interface, and the touch command can include controlli...

example

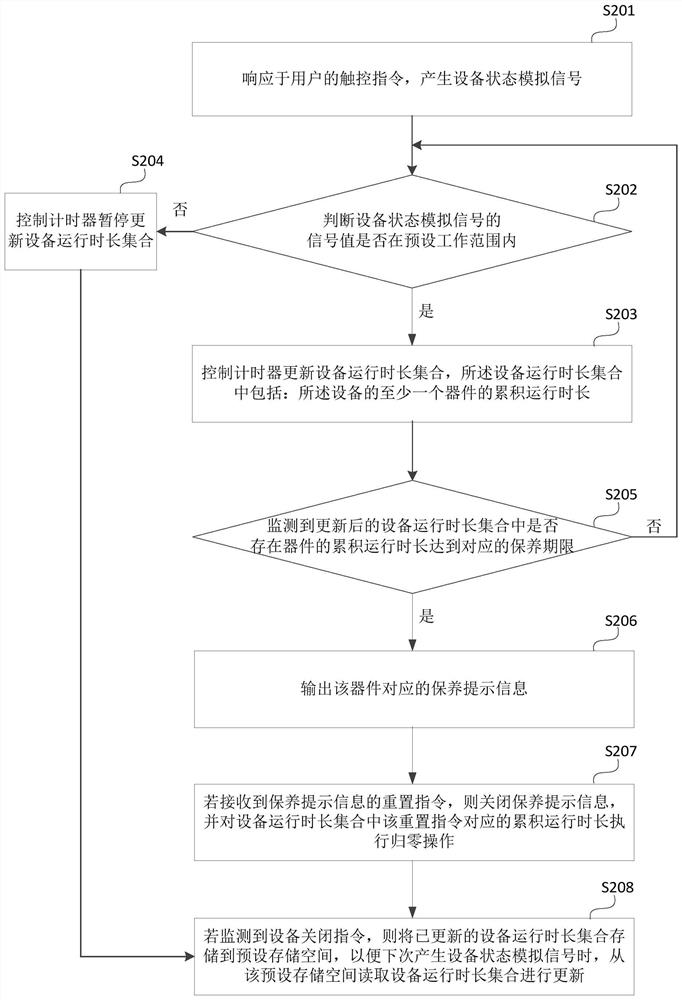

[0046] figure 2 It is a flow chart of an equipment maintenance reminder method provided by Embodiment 2 of the present invention. This embodiment is further optimized on the basis of the above embodiments, and a preferred example is provided. The method specifically includes:

[0047] S201. Generate a device state analog signal in response to a user's touch command.

[0048] S202, judging whether the signal value of the equipment status analog signal is within a preset working range, if yes, execute S203, and if not, execute S204.

[0049] Exemplarily, it may be judged whether the analog status signal of the device is within the preset working range. If so, it means that the device is in the working state, and S203 needs to be executed to update the cumulative running time of each device in the device running time set. If not, it means that the device is in a non-working state, then execute S204, and control the timer to stop updating the set of running time of the device. ...

Embodiment 3

[0065] image 3 A structural block diagram of an equipment maintenance reminder device provided by Embodiment 3 of the present invention. This device can be configured in any kind of mechanical equipment including an upper computer and a lower computer. The device can execute the above-mentioned Embodiment 1 and Embodiment 1 of the present invention. 2. The equipment maintenance reminder method provided, the corresponding functional modules and beneficial effects of the specific implementation method. Such as image 3 As shown, the device includes:

[0066] A state signal generating module 301, configured to generate a device state analog signal in response to a user's touch command;

[0067] The runtime update module 302 is configured to control the timer to update the device runtime set if the signal value of the device status analog signal is within the preset working range; the device runtime set includes: at least one of the devices The cumulative runtime of the device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com