A multipurpose automatic leveling device and leveling method

A level adjustment device and multi-purpose technology, which is applied in the direction of elastic deformation gauge fluid pressure measurement, instruments, instrument parts, etc., can solve the problems of low adjustment accuracy and low adjustment efficiency of ordinary automatic level adjustment devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

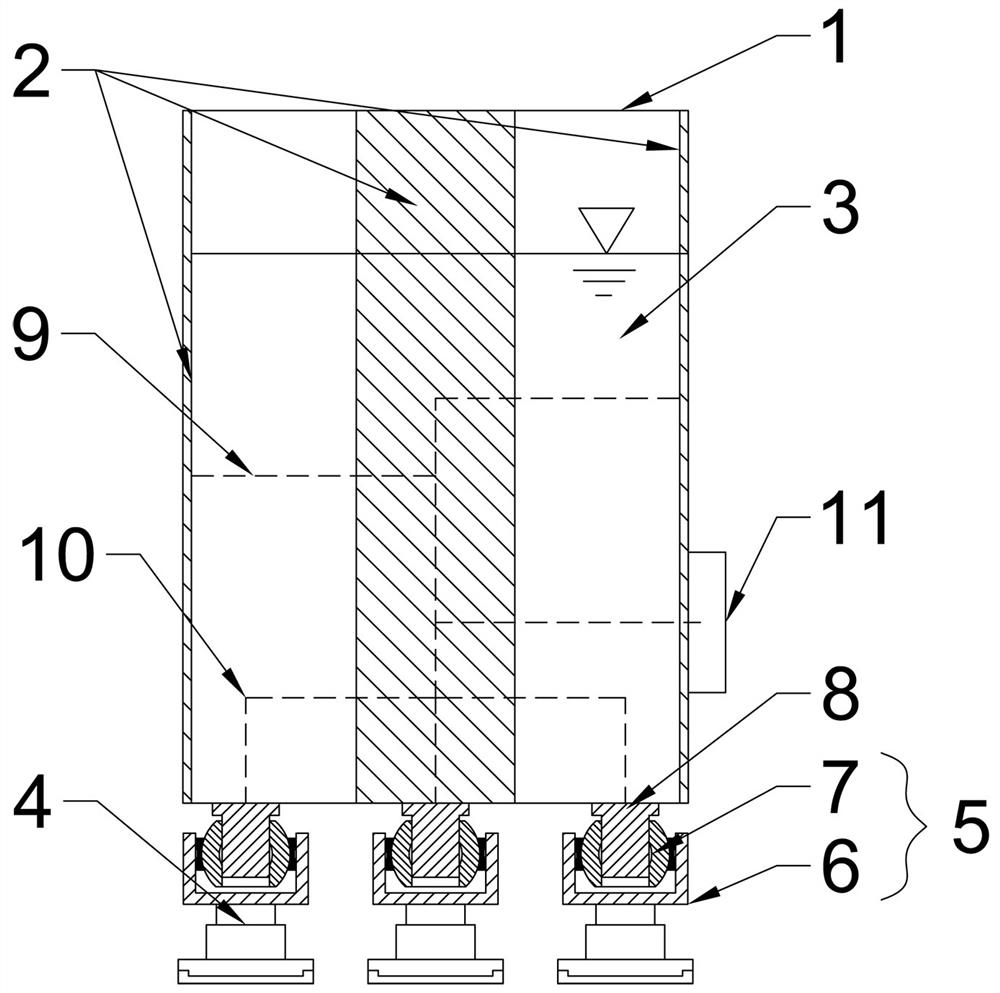

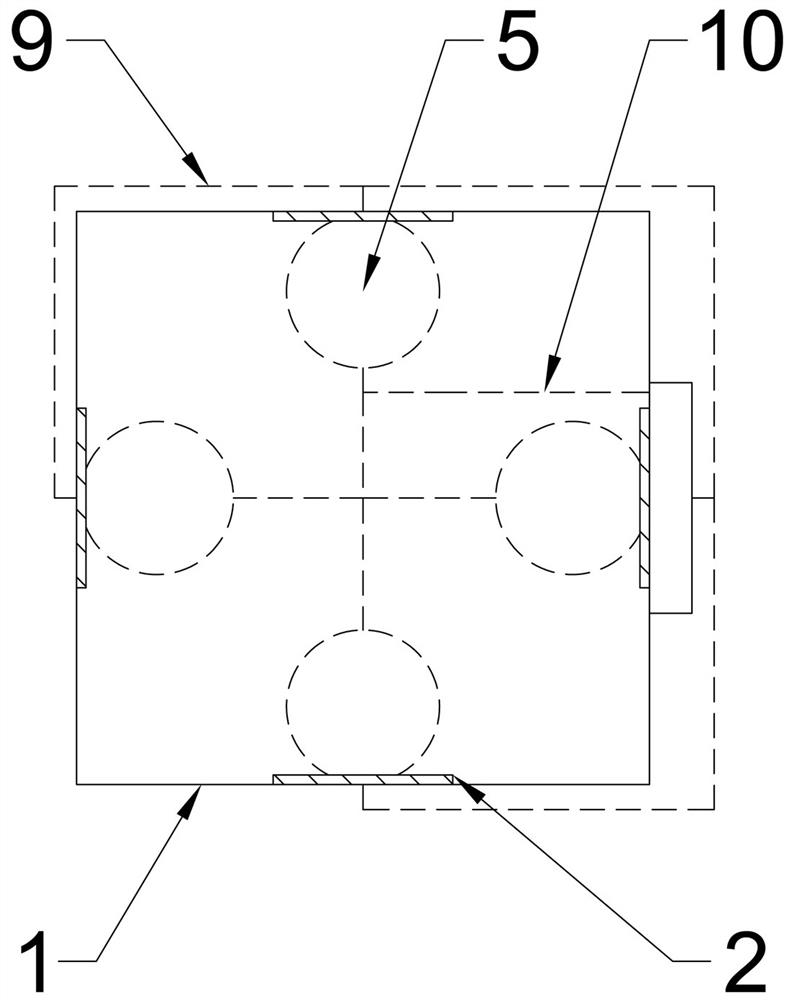

[0043] As shown in Figures 1 to 3, a multi-purpose automatic level adjustment device includes a pressure measurement assembly, an adjustment assembly, and a controller 11. A thin-film strain gauge pressure sensor 2 and a measuring liquid 3 stored in the liquid container 1;

[0044] The adjustment assembly includes a height adjustment member 4 and a direction adjuster 5, the height adjustment member 4 is arranged at the lower end and fixedly connected with the ground or the installation platform, and the direction adjuster 5 includes a fixed sleeve connected to the top of the height adjustment member 4 6 and the spherical joint 7 fitted in the fixed sleeve, the top of the spherical joint 7 is provided with a top plate 8 connected to the bottom of the liquid container 1; the pressure measurement assembly and the adjustment assembly are both connected to the controller 11.

[0045] The cross section of the liquid container 1 is square and the liquid container 1 is sealed as a who...

Embodiment 2

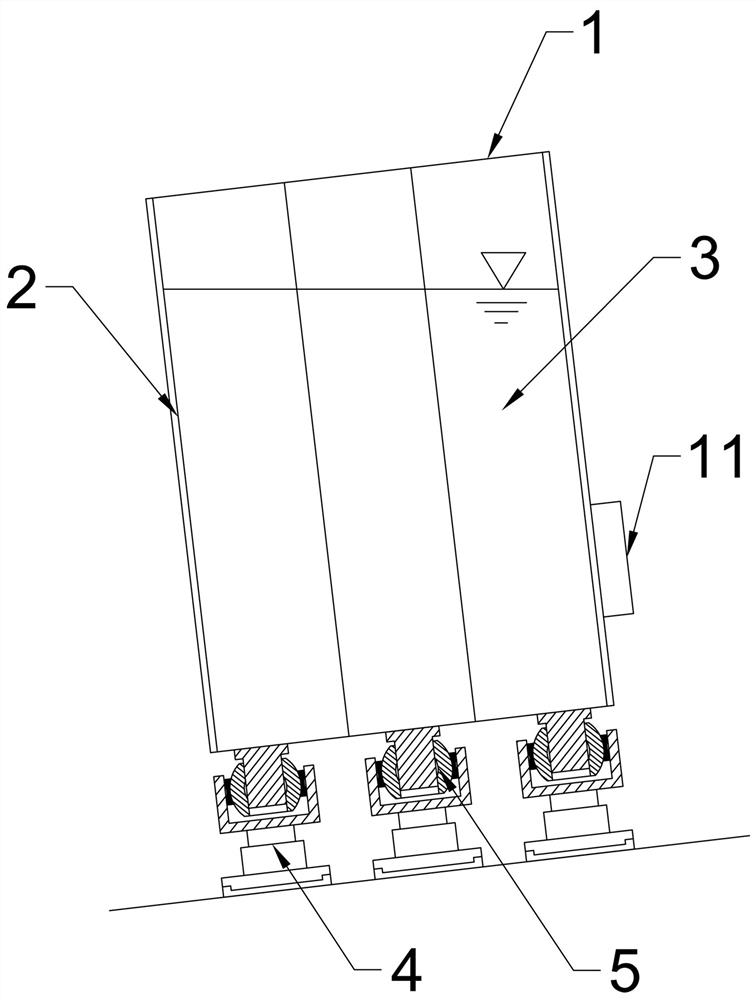

[0051] Such as Figure 4~8 As shown, a leveling method of a multi-purpose automatic level adjustment device includes a multi-purpose automatic level adjustment device described in Embodiment 1, and the leveling method includes the following steps:

[0052] Step 1.1, the thin film strain gauge pressure sensor 2 measures the pressure of the measuring liquid 3, and sends the measured pressure to the controller 11 through the pressure sensing data line 9;

[0053] Step 1.2, the controller 11 performs pressure data processing and analysis, and sends the action command to the height adjustment part 4 through the height adjustment data line 10;

[0054] In step 1.3, the height adjustment member 4 ends its action under the control of the controller 11 or performs a large-scale coarse adjustment program and a small-scale fine-adjustment program in sequence;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com